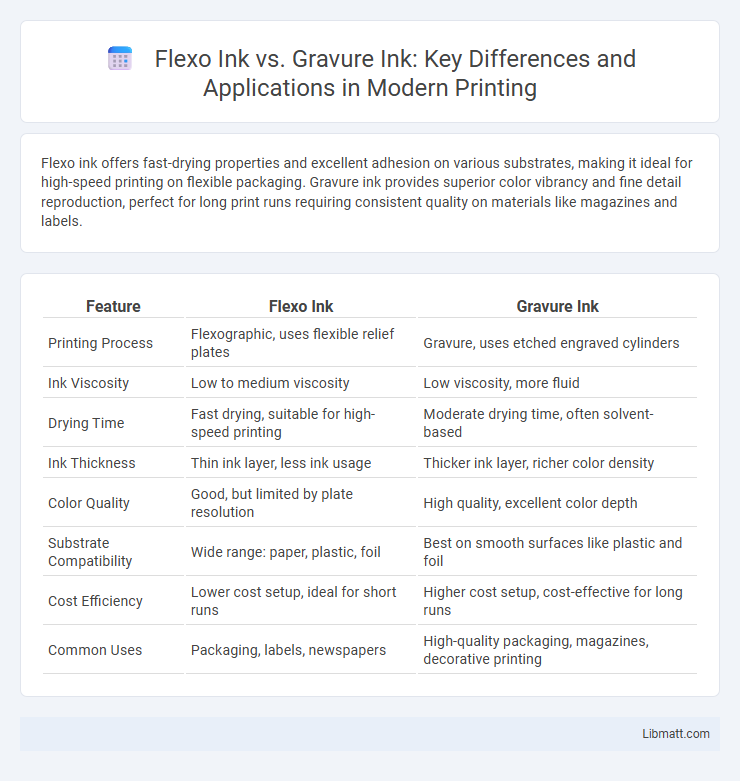

Flexo ink offers fast-drying properties and excellent adhesion on various substrates, making it ideal for high-speed printing on flexible packaging. Gravure ink provides superior color vibrancy and fine detail reproduction, perfect for long print runs requiring consistent quality on materials like magazines and labels.

Table of Comparison

| Feature | Flexo Ink | Gravure Ink |

|---|---|---|

| Printing Process | Flexographic, uses flexible relief plates | Gravure, uses etched engraved cylinders |

| Ink Viscosity | Low to medium viscosity | Low viscosity, more fluid |

| Drying Time | Fast drying, suitable for high-speed printing | Moderate drying time, often solvent-based |

| Ink Thickness | Thin ink layer, less ink usage | Thicker ink layer, richer color density |

| Color Quality | Good, but limited by plate resolution | High quality, excellent color depth |

| Substrate Compatibility | Wide range: paper, plastic, foil | Best on smooth surfaces like plastic and foil |

| Cost Efficiency | Lower cost setup, ideal for short runs | Higher cost setup, cost-effective for long runs |

| Common Uses | Packaging, labels, newspapers | High-quality packaging, magazines, decorative printing |

Introduction to Flexo Ink and Gravure Ink

Flexo ink and gravure ink are specialized printing inks used in different printing techniques, each offering unique properties tailored to specific applications. Flexo ink, designed for flexible packaging and labels, provides fast drying and excellent adhesion on various substrates. Gravure ink is known for its high-quality image reproduction and is commonly used in high-volume printing processes such as magazines and packaging, delivering rich, vibrant colors with precision.

Overview of Flexographic and Gravure Printing

Flexo Ink is designed for flexographic printing, a process that uses flexible relief plates for high-speed, cost-effective printing on various substrates such as plastic, paper, and foil. Gravure Ink is formulated for gravure printing, which employs engraved cylinders to produce high-quality, detailed images with vibrant color consistency, commonly used for packaging and labels. Understanding the differences in ink composition and printing techniques helps you choose the best option for your specific print project.

Key Differences in Ink Composition

Flexo ink is typically water-based or UV-curable, designed for fast drying and compatibility with flexible substrates, while gravure ink is solvent-based or UV ink, offering higher pigment concentration for superior print quality on high-speed rotary presses. The key difference lies in viscosity; flexo ink has lower viscosity to accommodate the anilox roller's metering system, whereas gravure ink has higher viscosity to fill engraved cells precisely. Understanding these ink composition differences helps optimize print results based on your packaging or labeling requirements.

Printing Substrate Compatibility

Flexo ink offers excellent compatibility with a wide range of printing substrates, including flexible films, paper, and corrugated materials, making it ideal for packaging applications. Gravure ink performs best on smooth, non-porous surfaces such as plastic films and metallic foils, providing superior image quality and color vibrancy. Understanding your printing substrate ensures optimal ink selection for durability and print clarity.

Color Reproduction and Print Quality

Flexo ink offers faster drying times and is ideal for high-speed printing but may produce less vibrant color reproduction compared to gravure ink, which delivers superior print quality with rich, consistent colors due to its ability to hold more ink in its engraved cells. Gravure ink's precision enhances image sharpness and detail, making it the preferred choice for premium packaging and high-resolution graphics. Your print project's quality demands will determine whether the vibrant intensity of gravure or the efficient coverage of flexo ink is more suitable.

Drying and Curing Processes

Flexo ink dries primarily through evaporation, which allows for faster drying times suitable for high-speed printing on porous substrates. Gravure ink requires a longer drying process, often relying on solvent evaporation and heat curing to ensure ink adhesion and durability on non-porous surfaces. Your choice between flexo and gravure inks depends on the drying efficiency needed for your specific printing application and material compatibility.

Environmental Impact and Sustainability

Flexo ink typically offers a lower environmental impact due to its water-based formulations and faster drying times, which reduce volatile organic compound (VOC) emissions compared to gravure ink. Gravure ink often contains higher solvent content, resulting in increased VOC emissions and greater ecological concerns during production and disposal. Sustainable printing practices favor flexo inks for their recyclability and reduced energy consumption, promoting greener packaging solutions.

Cost Considerations and Efficiency

Flexo ink generally offers lower cost considerations compared to gravure ink due to simpler plate production and faster setup times, making it suitable for shorter runs and quick job changes. Gravure ink, though more expensive upfront due to cylinder engraving and higher ink usage, provides greater efficiency in high-volume printing with consistent, high-quality output and reduced waste. Your choice between flexo and gravure ink should balance production volume and budget priorities to optimize overall printing efficiency.

Typical Applications and Industry Usage

Flexo ink is widely used in packaging industries for printing on flexible materials such as plastic films, paper, and cardboard, making it ideal for labels, bags, and corrugated boxes. Gravure ink is preferred in high-volume printing applications like magazines, catalogs, and decorative laminates due to its ability to produce fine detail and consistent color quality on materials like paper, plastic, and foil. Both inks serve crucial roles in commercial and industrial printing, with flexo favored for its fast-drying properties in flexible packaging and gravure for long-run, high-resolution print jobs.

Choosing the Right Ink for Your Printing Needs

Flexo ink offers fast drying times and excellent adhesion on a variety of substrates, making it ideal for flexible packaging and labels. Gravure ink provides superior color vibrancy and consistency, suited for high-quality, long-run printing projects such as magazines and premium packaging. Your choice should balance production speed, print quality, and substrate compatibility to ensure optimal results for your specific printing needs.

Flexo Ink vs Gravure Ink Infographic

libmatt.com

libmatt.com