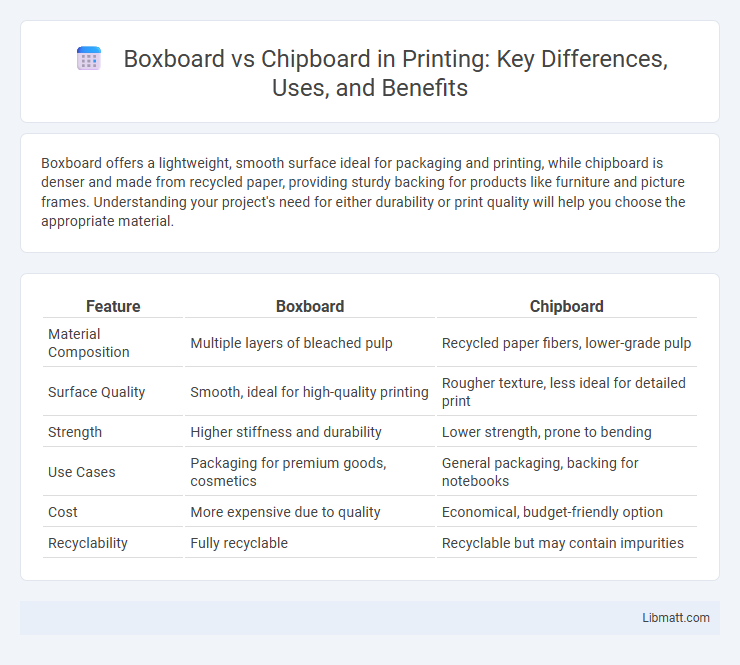

Boxboard offers a lightweight, smooth surface ideal for packaging and printing, while chipboard is denser and made from recycled paper, providing sturdy backing for products like furniture and picture frames. Understanding your project's need for either durability or print quality will help you choose the appropriate material.

Table of Comparison

| Feature | Boxboard | Chipboard |

|---|---|---|

| Material Composition | Multiple layers of bleached pulp | Recycled paper fibers, lower-grade pulp |

| Surface Quality | Smooth, ideal for high-quality printing | Rougher texture, less ideal for detailed print |

| Strength | Higher stiffness and durability | Lower strength, prone to bending |

| Use Cases | Packaging for premium goods, cosmetics | General packaging, backing for notebooks |

| Cost | More expensive due to quality | Economical, budget-friendly option |

| Recyclability | Fully recyclable | Recyclable but may contain impurities |

Introduction to Boxboard and Chipboard

Boxboard, typically made from multiple layers of paperboard, offers rigidity and lightweight strength, making it ideal for packaging and printing applications. Chipboard, produced from recycled paper pulp, is denser and more economical, commonly used in backing for notepads, book covers, and furniture components. Both materials differ in composition and performance properties, influencing their suitability across various industrial uses.

Defining Boxboard: Key Features

Boxboard is a lightweight, multi-ply paperboard known for its smooth surface and superior printing quality, making it ideal for packaging and folding cartons. It typically consists of a bleached virgin fiber top layer, offering excellent stiffness and durability compared to chipboard. The versatility and enhanced strength of boxboard provide better resistance to bending and moisture, distinguishing it from the more porous and rough-textured chipboard.

Defining Chipboard: Key Features

Chipboard, commonly known as particle board, is engineered from wood chips, sawdust, and adhesive resin, pressed into dense, rigid sheets. Its key features include affordability, moderate strength, and a rough texture, making it ideal for low-cost furniture, packaging, and backing materials. Unlike boxboard, chipboard lacks smooth surface finishes, requiring lamination or coating for enhanced durability and aesthetic appeal.

Material Composition Differences

Boxboard primarily consists of multiple layers of bleached chemical pulp, providing a smooth surface and high strength, ideal for consumer packaging. Chipboard is made from recycled paper fibers and wood chips, resulting in a denser, rougher texture with lower durability. The material composition differences affect their recyclability, print quality, and structural performance in packaging applications.

Strength and Durability Comparison

Boxboard features multiple layers of paperboard, providing superior strength and durability compared to chipboard, which is made from recycled paper fibers and often contains visible wood chips. The stiffness and resistance to bending in boxboard make it ideal for packaging that requires protection during handling and shipping. Your choice depends on the level of durability needed, with boxboard excelling in robustness while chipboard suits lightweight or less demanding applications.

Common Applications of Boxboard

Boxboard is widely used in packaging for products such as cereals, cosmetics, and pharmaceuticals due to its lightweight yet sturdy nature. Its smooth surface allows for high-quality printing, making it ideal for retail displays and folding cartons that require attractive branding. You can rely on boxboard for eco-friendly packaging solutions that also provide adequate protection during shipping.

Common Uses of Chipboard

Chipboard is commonly used in packaging, bookbinding, and furniture manufacturing due to its cost-effectiveness and durability. It serves as a backing material for notepads, picture frames, and as the core in laminate flooring and cabinets. Your choice of chipboard benefits from its versatility in producing sturdy yet lightweight products across various industries.

Environmental Impact and Sustainability

Boxboard typically has a lower environmental impact than chipboard due to its higher recyclability and the use of renewable fiber sources. Chipboard often contains recycled content but may include adhesives and coatings that hinder biodegradability and recycling processes. Choosing boxboard can enhance your sustainability efforts by supporting materials with better end-of-life options and reduced ecological footprints.

Cost Comparison: Boxboard vs Chipboard

Boxboard generally costs more than chipboard due to its higher quality, durability, and smoother surface, which makes it ideal for packaging that requires printing and aesthetics. Chipboard is an economical option often used for less demanding applications such as backing or filler material, offering a sturdy but rougher texture. Your choice hinges on balancing budget constraints with the required performance and appearance of the final product.

Choosing the Right Material for Your Packaging Needs

Boxboard offers superior printability and smooth surface quality, making it ideal for high-end retail packaging and product presentation. Chipboard provides cost-effective rigidity and durability, suitable for structural support in shipping containers or backing materials. Selecting between boxboard and chipboard depends on balancing aesthetics, strength requirements, and budget constraints to optimize packaging performance.

boxboard vs chipboard Infographic

libmatt.com

libmatt.com