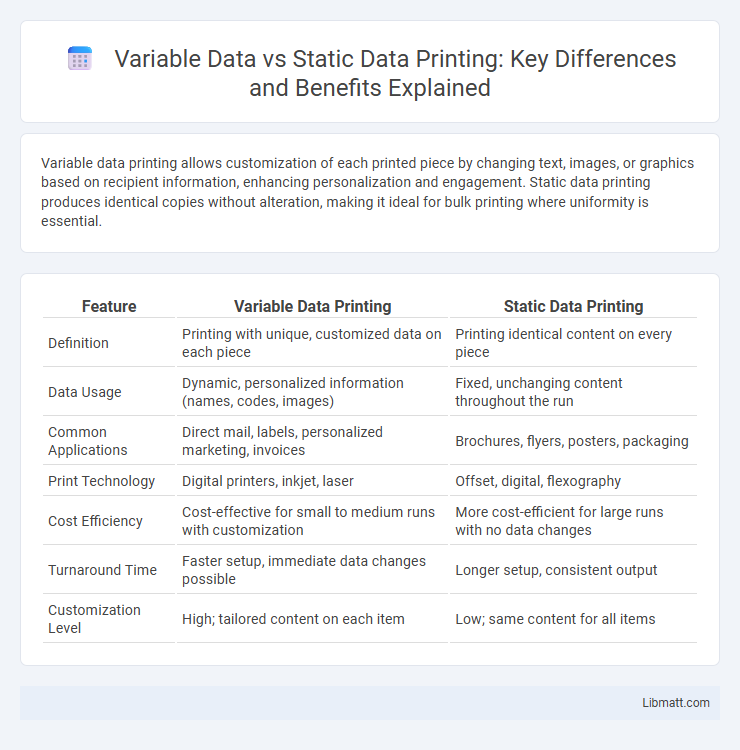

Variable data printing allows customization of each printed piece by changing text, images, or graphics based on recipient information, enhancing personalization and engagement. Static data printing produces identical copies without alteration, making it ideal for bulk printing where uniformity is essential.

Table of Comparison

| Feature | Variable Data Printing | Static Data Printing |

|---|---|---|

| Definition | Printing with unique, customized data on each piece | Printing identical content on every piece |

| Data Usage | Dynamic, personalized information (names, codes, images) | Fixed, unchanging content throughout the run |

| Common Applications | Direct mail, labels, personalized marketing, invoices | Brochures, flyers, posters, packaging |

| Print Technology | Digital printers, inkjet, laser | Offset, digital, flexography |

| Cost Efficiency | Cost-effective for small to medium runs with customization | More cost-efficient for large runs with no data changes |

| Turnaround Time | Faster setup, immediate data changes possible | Longer setup, consistent output |

| Customization Level | High; tailored content on each item | Low; same content for all items |

Understanding Variable Data Printing

Variable data printing (VDP) allows customization of printed materials by changing elements such as text, images, or graphics from one piece to the next without stopping the print run, providing personalized marketing and communication solutions. Unlike static data printing, where each copy is identical, VDP uses digital files and databases to tailor content, enhancing customer engagement and response rates. This method is widely used in direct mail campaigns, invoices, and customized promotional materials to increase relevance and effectiveness.

Defining Static Data Printing

Static data printing involves producing consistent, unchanging information on each printed item, commonly used for materials like flyers, brochures, and packaging labels. This method ensures uniformity and cost-efficiency when mass-producing identical copies without personalization. Your print jobs with static data remain constant, making it ideal for standard marketing collateral and product information.

Key Differences Between Variable and Static Data Printing

Variable data printing customizes each printed piece with unique information such as names, addresses, or images, enabling personalized marketing campaigns and targeted communications. Static data printing uses the same content on every printed piece, ideal for bulk production of consistent materials like brochures or flyers. Understanding these key differences helps you choose the right printing method for your project's goals and budget efficiency.

Benefits of Variable Data Printing

Variable Data Printing (VDP) offers significant advantages over static data printing by enabling personalized content for each printed piece, which increases engagement and response rates. This technology allows for cost-effective, on-demand customization, reducing waste and lead times while targeting specific audiences with tailored messages. Your marketing campaigns become more impactful through relevant communication that drives higher conversion rates and customer loyalty.

Advantages of Static Data Printing

Static data printing ensures consistent, high-quality output ideal for mass production, reducing setup times and minimizing errors. It simplifies the printing process by maintaining uniform information across all copies, which is cost-effective for large print runs. This method streamlines inventory management and speeds up workflow when variable data customization is unnecessary.

Common Applications of Variable Data Printing

Variable data printing is widely utilized in personalized direct mail campaigns, enabling unique text, images, and graphics tailored to each recipient. It is essential in customized marketing materials, such as brochures and flyers, that adapt messages based on customer demographics or purchasing behavior. Other common applications include personalized labels, invoices, and event tickets, which require dynamic content for identification and tracking purposes.

Use Cases for Static Data Printing

Static data printing is ideal for producing materials such as brochures, flyers, labels, and packaging where consistent information appears across multiple copies. Industries like manufacturing, retail, and publishing rely on this method for branding and mass communication because it ensures uniformity and cost-effectiveness. Your business benefits from static data printing when uniformity and high-volume output with fixed content are essential.

Personalization in Variable Data Printing

Variable data printing enables high levels of personalization by dynamically changing text, images, and graphics for each printed piece, unlike static data printing where the content remains constant. By using databases and digital files, variable data printing tailors marketing materials, invoices, and direct mail to individual recipients, increasing engagement and response rates. Your brand can leverage this technology to create customized communication that resonates with recipients on a personal level, driving better customer relationships and campaign performance.

Workflow and Technology Comparison

Variable data printing (VDP) utilizes digital printing technology to customize each printed piece with unique information, enabling highly personalized marketing materials and direct mail campaigns. Static data printing relies on traditional offset or letterpress methods, producing large volumes of identical copies with consistent content, optimizing speed and cost-efficiency for repetitive jobs. VDP workflows incorporate complex software for data management and variable image processing, whereas static printing workflows emphasize plate creation and press setup, resulting in fundamentally different technology requirements and production timelines.

Choosing Between Variable and Static Data Printing

Choosing between variable and static data printing depends on your project requirements; variable data printing customizes each printed piece with unique information, ideal for personalized marketing or direct mail campaigns. Static data printing produces identical copies, suitable for consistent branding materials or large-scale manufacturing. Your decision should factor in the need for customization, production volume, and cost-efficiency to ensure the best printing solution.

Variable data vs static data printing Infographic

libmatt.com

libmatt.com