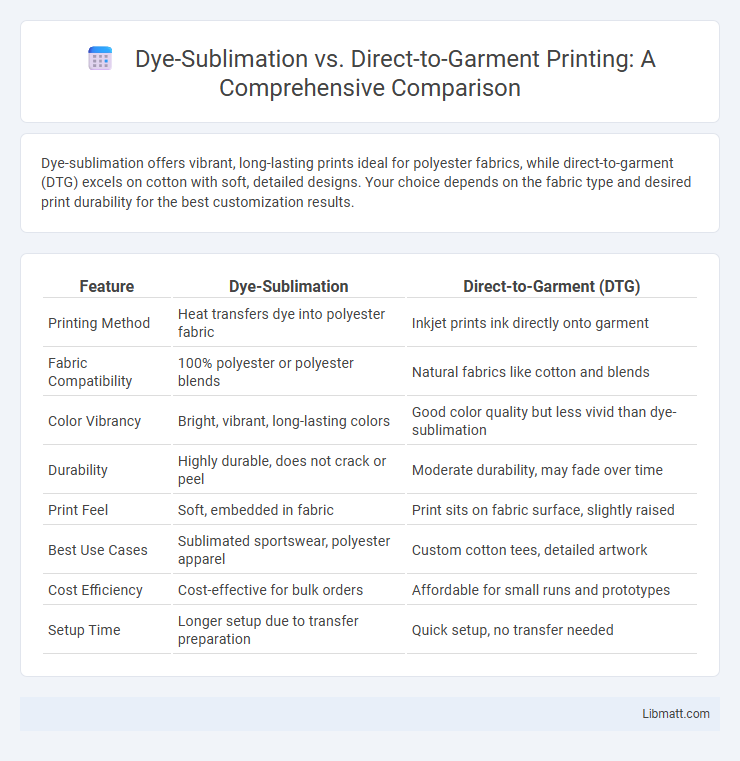

Dye-sublimation offers vibrant, long-lasting prints ideal for polyester fabrics, while direct-to-garment (DTG) excels on cotton with soft, detailed designs. Your choice depends on the fabric type and desired print durability for the best customization results.

Table of Comparison

| Feature | Dye-Sublimation | Direct-to-Garment (DTG) |

|---|---|---|

| Printing Method | Heat transfers dye into polyester fabric | Inkjet prints ink directly onto garment |

| Fabric Compatibility | 100% polyester or polyester blends | Natural fabrics like cotton and blends |

| Color Vibrancy | Bright, vibrant, long-lasting colors | Good color quality but less vivid than dye-sublimation |

| Durability | Highly durable, does not crack or peel | Moderate durability, may fade over time |

| Print Feel | Soft, embedded in fabric | Print sits on fabric surface, slightly raised |

| Best Use Cases | Sublimated sportswear, polyester apparel | Custom cotton tees, detailed artwork |

| Cost Efficiency | Cost-effective for bulk orders | Affordable for small runs and prototypes |

| Setup Time | Longer setup due to transfer preparation | Quick setup, no transfer needed |

Introduction to Fabric Printing Technologies

Dye-sublimation and direct-to-garment (DTG) are leading fabric printing technologies that offer distinct advantages for customizing apparel. Dye-sublimation infuses ink into polyester fibers, producing vibrant, long-lasting prints ideal for synthetic fabrics, while DTG uses specialized inkjet printers to apply designs directly onto cotton and natural fiber garments, enabling detailed, full-color prints. Your choice depends on the fabric type and desired print quality, with dye-sublimation excelling in durability and DTG offering versatility for diverse clothing materials.

What is Dye-Sublimation Printing?

Dye-sublimation printing is a process that uses heat to transfer dye onto materials like polyester fabric or coated surfaces, creating vibrant, permanent images. This technique involves converting solid dye into gas without passing through a liquid phase, allowing deep ink penetration that resists fading and cracking. Ideal for synthetic materials, dye-sublimation produces high-resolution, full-color designs with exceptional durability compared to other printing methods.

What is Direct-to-Garment (DTG) Printing?

Direct-to-Garment (DTG) printing is a digital process that uses specialized inkjet technology to apply water-based inks directly onto fabrics, producing high-quality, detailed designs with a soft feel. This method is ideal for small to medium print runs and excels in reproducing vibrant colors and intricate patterns on cotton and cotton-blend garments. Your custom apparel projects benefit from DTG's quick setup time and minimal waste compared to traditional screen printing techniques.

Print Quality: Comparing Results

Dye-sublimation produces vibrant, long-lasting prints with excellent color saturation and smooth gradients, especially on polyester fabrics. Direct-to-garment (DTG) excels at detailed, full-color designs on cotton garments but may show less vibrancy on darker fabrics without pre-treatment. For durability, dye-sublimation inks penetrate fabric fibers, resisting fading and cracking better than DTG's surface-level ink application.

Material Compatibility and Limitations

Dye-sublimation works best on polyester or polyester-coated materials, producing vibrant, durable prints but struggles with natural fabrics like cotton, which limits its use for all-cotton garments. Direct-to-garment (DTG) printing is compatible with 100% cotton and cotton blends, offering high detail and color range but may lack the durability of dye-sublimation on synthetic fibers. When choosing between these methods, consider your material type and the end-use of your product to ensure optimal print quality and longevity.

Color Vibrancy and Longevity

Dye-sublimation delivers exceptional color vibrancy by infusing ink directly into polyester fibers, resulting in bright, long-lasting prints that resist fading and cracking over time. Direct-to-garment (DTG) printing offers a softer feel with accurate color reproduction on cotton fabrics, but its vibrancy and durability may diminish faster with repeated washing. Choosing dye-sublimation ensures your designs maintain intense, vivid colors and extended longevity, especially on polyester-based garments.

Production Speed and Efficiency

Dye-sublimation offers faster production speeds for large, continuous runs due to its ability to print entire designs in a single pass, making it highly efficient for polyester fabrics. Direct-to-garment (DTG) printing is slower as it prints each garment individually, but excels in producing intricate, full-color designs on cotton with less setup time for small batches. For your business, choosing between dye-sublimation and DTG hinges on whether you prioritize high-volume output speed or flexible customization efficiency.

Cost Comparison: Setup and Printing

Dye-sublimation involves higher initial setup costs due to specialized heat transfer equipment and polyester-compatible inks, but offers low per-print expenses ideal for large batches. Direct-to-garment (DTG) requires less upfront investment, focusing on inkjet printers that handle various fabric types, making it cost-effective for small runs. Your choice depends on print volume and fabric compatibility, balancing setup and printing expenditures for optimal budget efficiency.

Environmental Impact and Sustainability

Dye-sublimation printing uses environmentally friendly water-based inks and produces less waste due to its precise application on polyester fabrics, making it a sustainable choice for synthetic textiles. Direct-to-garment (DTG) printing allows for lower energy consumption by printing only the required quantity, reducing overproduction and fabric waste but relies on water-intensive pre-treatment processes. Both methods benefit from advancements in eco-friendly inks and recyclable materials, with dye-sublimation favored for longevity and DTG praised for versatility in sustainable garment printing.

Choosing the Right Method for Your Project

Dye-sublimation excels in producing vibrant, long-lasting designs on polyester fabrics, making it ideal for lightweight sportswear and promotional items. Direct-to-garment printing works best on cotton or cotton-blend materials, offering versatility and high detail for customized apparel with complex color patterns. Evaluating your fabric type, design complexity, and project volume will help you determine the most effective printing method for your needs.

Dye-Sublimation vs Direct-to-Garment Infographic

libmatt.com

libmatt.com