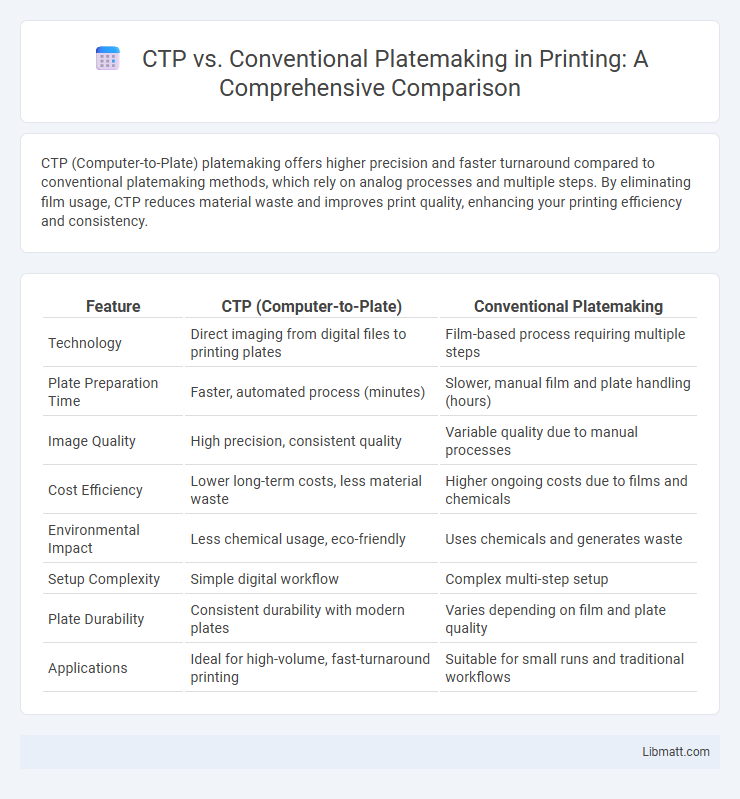

CTP (Computer-to-Plate) platemaking offers higher precision and faster turnaround compared to conventional platemaking methods, which rely on analog processes and multiple steps. By eliminating film usage, CTP reduces material waste and improves print quality, enhancing your printing efficiency and consistency.

Table of Comparison

| Feature | CTP (Computer-to-Plate) | Conventional Platemaking |

|---|---|---|

| Technology | Direct imaging from digital files to printing plates | Film-based process requiring multiple steps |

| Plate Preparation Time | Faster, automated process (minutes) | Slower, manual film and plate handling (hours) |

| Image Quality | High precision, consistent quality | Variable quality due to manual processes |

| Cost Efficiency | Lower long-term costs, less material waste | Higher ongoing costs due to films and chemicals |

| Environmental Impact | Less chemical usage, eco-friendly | Uses chemicals and generates waste |

| Setup Complexity | Simple digital workflow | Complex multi-step setup |

| Plate Durability | Consistent durability with modern plates | Varies depending on film and plate quality |

| Applications | Ideal for high-volume, fast-turnaround printing | Suitable for small runs and traditional workflows |

Introduction to Platemaking Technologies

Computer-to-Plate (CTP) technology revolutionizes platemaking by directly transferring digital images onto printing plates, eliminating intermediate film steps typical in conventional platemaking. Conventional platemaking involves creating films from digital files, which are then used to expose plates, introducing potential errors and longer processing times. CTP enhances print quality, reduces material waste, and accelerates production workflows in offset printing processes.

What is CTP (Computer-to-Plate)?

CTP (Computer-to-Plate) is a digital imaging technology that directly transfers digital files from a computer to printing plates, eliminating the need for intermediate film. This process enhances precision, reduces production time, and improves print quality by minimizing manual handling and errors associated with conventional platemaking. Compared to traditional methods, CTP offers higher consistency and cost-efficiency in prepress workflows.

Overview of Conventional Platemaking

Conventional platemaking involves creating printing plates through a film-based process where negatives are exposed onto photosensitive materials, requiring multiple manual steps and chemical processing. Unlike Computer-to-Plate (CTP) technology, this traditional method can lead to longer production times and potential quality inconsistencies due to human error. Your printing workflow may experience delays and increased costs with conventional platemaking compared to the streamlined, digital approach of CTP.

Workflow Comparison: CTP vs Conventional

Computer-to-Plate (CTP) technology streamlines the workflow by directly transferring digital files to the printing plate, eliminating intermediate steps typical in conventional platemaking, such as film processing. This leads to faster turnaround times, reduced material waste, and enhanced plate accuracy, improving overall print quality. Optimizing your printing workflow with CTP can result in consistent output and significant cost savings compared to traditional film-based methods.

Image Quality and Resolution Differences

CTP (Computer-to-Plate) technology offers superior image quality and higher resolution compared to conventional platemaking methods, providing sharper details and more accurate reproduction of fine lines and text. Your prints benefit from the consistent precision of digital imaging, which reduces errors associated with film and manual handling. Enhanced resolution in CTP results in smoother gradients and improved color fidelity, making it ideal for high-end commercial printing applications.

Speed and Efficiency: Time Savings Analyzed

CTP (Computer-to-Plate) technology significantly reduces platemaking time by eliminating film processing and manual plate making steps, resulting in faster turnaround compared to conventional platemaking. The direct digital transfer of images to plates enhances workflow efficiency, minimizing errors and rework. You benefit from expedited production schedules and cost savings due to streamlined operations.

Environmental Impact of Both Methods

CTP (Computer-to-Plate) significantly reduces environmental waste by eliminating the need for film and chemicals used in Conventional Platemaking, lowering water and solvent consumption. This method produces less hazardous waste and supports eco-friendly printing practices, enhancing sustainability in print production. Your choice of CTP can contribute to minimizing the carbon footprint and promoting greener operations in the industry.

Cost Analysis: Initial Investment and Running Costs

CTP (Computer-to-Plate) systems require a higher initial investment compared to conventional platemaking due to advanced digital equipment and software needs. However, CTP reduces running costs by eliminating film, chemicals, and manual processes, increasing overall efficiency. Your printing operation can achieve long-term savings and improved print quality despite the upfront expense.

Maintenance and Reliability Considerations

CTP (Computer-to-Plate) systems offer lower maintenance requirements and higher reliability compared to conventional platemaking, due to fewer mechanical parts and automated processes that reduce human error. Conventional platemaking involves chemical processing and manual handling, increasing the risk of equipment wear, contamination, and downtime. Your printing operations benefit from CTP's streamlined workflow and consistent plate quality, minimizing maintenance costs and improving overall pressroom efficiency.

Future Trends in Platemaking Technology

CTP (Computer-to-Plate) technology is rapidly evolving with advancements in high-resolution laser imaging and automation, increasing efficiency and print quality over Conventional Platemaking. The integration of AI-driven diagnostics and cloud-based workflows enables real-time monitoring and predictive maintenance, reducing downtime and waste. Sustainable materials and eco-friendly processes are becoming standard in CTP systems, aligning with industry trends toward greener printing solutions.

CTP vs Conventional Platemaking Infographic

libmatt.com

libmatt.com