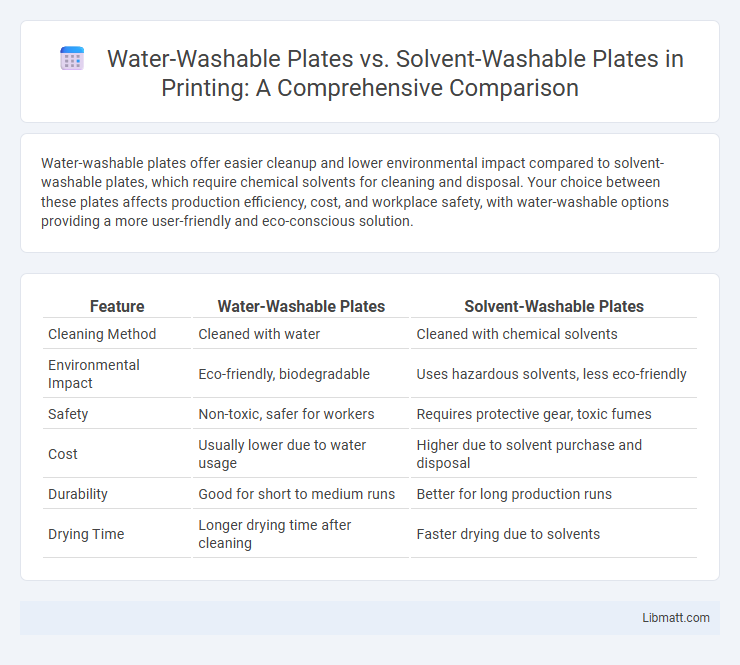

Water-washable plates offer easier cleanup and lower environmental impact compared to solvent-washable plates, which require chemical solvents for cleaning and disposal. Your choice between these plates affects production efficiency, cost, and workplace safety, with water-washable options providing a more user-friendly and eco-conscious solution.

Table of Comparison

| Feature | Water-Washable Plates | Solvent-Washable Plates |

|---|---|---|

| Cleaning Method | Cleaned with water | Cleaned with chemical solvents |

| Environmental Impact | Eco-friendly, biodegradable | Uses hazardous solvents, less eco-friendly |

| Safety | Non-toxic, safer for workers | Requires protective gear, toxic fumes |

| Cost | Usually lower due to water usage | Higher due to solvent purchase and disposal |

| Durability | Good for short to medium runs | Better for long production runs |

| Drying Time | Longer drying time after cleaning | Faster drying due to solvents |

Introduction to Photopolymer Plates

Photopolymer plates are essential in modern flexographic printing, offering high-resolution image reproduction and consistent performance. Water-washable plates use water and mild detergents for cleanup, making them environmentally friendly and safer for workers, while solvent-washable plates require chemical solvents that provide faster drying times but involve health and environmental risks. Your choice depends on the balance between eco-friendliness and production speed in your printing process.

Overview: Water-Washable vs Solvent-Washable Plates

Water-washable plates utilize water-based emulsions that eliminate the need for harsh chemicals, offering a more environmentally friendly and safer cleaning process ideal for frequent use in flexographic printing. Solvent-washable plates rely on chemical solvents to remove ink residues, providing quick cleaning and superior ink release, but require careful handling due to potential health and environmental risks. Choosing between these plates depends on production volume, environmental considerations, and cleaning efficiency requirements within the printing workflow.

Plate Material Composition

Water-washable plates typically consist of photopolymer materials designed to be cleaned with water, featuring hydrophilic polymer layers that facilitate easy and environmentally friendly rinsing. Solvent-washable plates are composed of traditional photopolymers with hydrophobic properties, requiring organic solvents like alcohol or specialized chemicals for effective ink removal and cleaning. The difference in plate material composition directly affects the cleaning process, environmental impact, and compatibility with printing inks.

Processing and Washout Methods

Water-washable plates use a process that eliminates the need for harsh chemicals by dissolving the image area with water, allowing easier and safer cleanup while reducing environmental impact. Solvent-washable plates require chemical solvents to remove unexposed polymer, offering potentially faster processing times but demanding careful handling and disposal of hazardous materials. Your choice between these plates affects workflow efficiency, safety protocols, and environmental considerations based on the preferred washout method.

Environmental Impact and Sustainability

Water-washable plates significantly reduce environmental impact by eliminating the use of harmful solvents, leading to lower VOC emissions and reduced hazardous waste generation. These plates promote sustainability through easier recycling and safer disposal processes, ultimately preserving ecosystems and improving workplace safety. In contrast, solvent-washable plates require chemical solvents that contribute to pollution and increase the carbon footprint of printing operations.

Cost Efficiency and Operational Considerations

Water-washable plates reduce costs by eliminating the need for expensive solvents, lowering both material expenses and disposal fees, while also minimizing health risks and environmental impact. Solvent-washable plates often require specialized handling equipment and ventilation systems, increasing operational complexity and maintenance costs. Choosing water-washable plates enhances cost efficiency through simpler cleaning processes and faster turnaround, making them ideal for high-volume printing environments.

Print Quality and Performance

Water-washable plates offer sharp, high-resolution prints with consistent dot quality, making them ideal for fine detail and vibrant color reproduction. Solvent-washable plates provide excellent durability and chemical resistance, resulting in reliable performance during long print runs and in harsh production environments. Your choice should align with the specific demands of your print job, balancing enhanced print clarity against the need for plate longevity and chemical resilience.

Safety and Workplace Health

Water-washable plates significantly enhance workplace safety by reducing exposure to harmful chemicals and volatile organic compounds commonly found in solvent-washable plates, thereby minimizing respiratory risks and skin irritation for your employees. These plates eliminate the need for toxic solvents, creating a healthier environment and lowering the risk of fire hazards associated with flammable cleaning agents. Prioritizing water-washable plates contributes to compliance with occupational health standards and promotes a safer, more sustainable printing operation.

Maintenance and Storage Requirements

Water-washable plates require less maintenance since they can be cleaned with water, reducing the need for harsh chemicals and simplifying storage by eliminating flammable solvents. Solvent-washable plates demand careful handling and storage in well-ventilated areas due to the flammable and toxic nature of the solvents used, increasing maintenance complexity. Your choice impacts the ease of cleaning routines and the safety measures necessary for proper storage.

Choosing the Best Plate for Your Application

Water-washable plates are ideal for applications requiring fast, eco-friendly cleaning and reduced solvent exposure, improving operator safety and minimizing environmental impact. Solvent-washable plates offer superior chemical resistance and are preferred for applications involving heavy ink deposits or solvent-based inks, ensuring durability and consistent print quality. Selecting the best plate depends on factors such as ink type, cleaning method compatibility, environmental regulations, and production workflow demands.

Water-washable plates vs solvent-washable plates Infographic

libmatt.com

libmatt.com