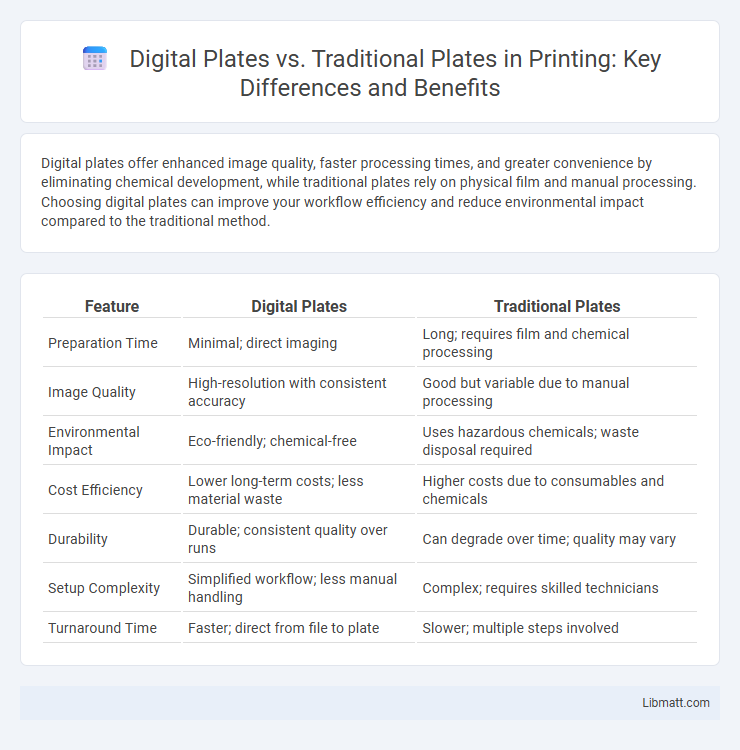

Digital plates offer enhanced image quality, faster processing times, and greater convenience by eliminating chemical development, while traditional plates rely on physical film and manual processing. Choosing digital plates can improve your workflow efficiency and reduce environmental impact compared to the traditional method.

Table of Comparison

| Feature | Digital Plates | Traditional Plates |

|---|---|---|

| Preparation Time | Minimal; direct imaging | Long; requires film and chemical processing |

| Image Quality | High-resolution with consistent accuracy | Good but variable due to manual processing |

| Environmental Impact | Eco-friendly; chemical-free | Uses hazardous chemicals; waste disposal required |

| Cost Efficiency | Lower long-term costs; less material waste | Higher costs due to consumables and chemicals |

| Durability | Durable; consistent quality over runs | Can degrade over time; quality may vary |

| Setup Complexity | Simplified workflow; less manual handling | Complex; requires skilled technicians |

| Turnaround Time | Faster; direct from file to plate | Slower; multiple steps involved |

Introduction to Plate Technologies

Digital plates utilize computer-to-plate (CTP) technology, enabling direct imaging from digital files onto printing plates, which enhances precision and reduces setup time. Traditional plates rely on analog processes such as photographic film for plate creation, often leading to increased material waste and longer production cycles. Advancements in plate technologies have significantly improved print quality, efficiency, and environmental sustainability in modern printing workflows.

What Are Digital Plates?

Digital plates are advanced metal or plastic plates embedded with electronic components that allow for dynamic data display and real-time updates. Unlike traditional plates, which are static and require physical replacement for any changes, digital plates can display variable information such as vehicle details or registration status via digital screens. Your vehicle benefits from enhanced security, customization, and instant data verification through the integration of digital plate technology.

Overview of Traditional Plates

Traditional plates, commonly used in printmaking and manufacturing, are typically made from metal or plastic materials etched or engraved to create raised or recessed images. These plates require physical handling during processes like lithography, letterpress, or flexography, relying on manual or mechanical pressure to transfer ink onto substrates such as paper or fabric. Despite their durability and tactile quality, traditional plates involve longer setup times, higher material costs, and less flexibility compared to digital alternatives.

Key Differences Between Digital and Traditional Plates

Digital plates use electronic screens to display and change information instantly, offering high customization and easy updates without physical replacements. Traditional plates rely on fixed materials like metal or plastic, requiring manual changes and physical storage. Your choice depends on flexibility needs, cost considerations, and the frequency of updates required for plate information.

Printing Quality Comparison

Digital plates deliver superior printing quality through precise image reproduction and consistent dot clarity, reducing errors and enhancing fine detail visibility. Traditional plates may experience variability in image sharpness and dot gain, leading to less consistent output, especially in high-resolution prints. The advanced technology behind digital plates ensures sharper, more vibrant images with improved color accuracy compared to conventional plate methods.

Cost Analysis: Digital vs Traditional Plates

Digital plates offer a cost-efficient alternative to traditional plates by reducing setup time and material waste in printing processes. Traditional plates often incur higher expenses due to chemical usage, manual labor, and longer production cycles. Your business can achieve significant savings and faster turnaround times by opting for digital plates in printing workflows.

Production Speed and Efficiency

Digital plates dramatically reduce production speed by eliminating time-consuming chemical processing steps required in traditional plate-making methods. The efficiency of digital plates is enhanced through direct imaging technology, which decreases setup time and waste while enabling faster turnaround for print jobs. Traditional plates rely on manual handling and chemical development, leading to slower production cycles and higher resource consumption compared to the streamlined digital process.

Environmental Impact and Sustainability

Digital plates significantly reduce environmental impact by minimizing waste associated with traditional plate-making methods, which often involve hazardous chemicals and metal disposal. They use reusable materials and require less energy and water during production, contributing to greater sustainability in printing processes. This shift supports eco-friendly practices by lowering carbon footprints and conserving natural resources compared to conventional plates.

Industry Applications and Use Cases

Digital plates enhance industry applications by offering rapid customization and cost-effective production for sectors like packaging, automotive, and textiles, outperforming traditional plates in efficiency and precision. These plates support high-resolution printing in commercial publishing and flexible label manufacturing, enabling faster turnaround times and reducing setup errors. Traditional plates remain prevalent in large-volume, long-run printing where their durability and established processes meet consistent quality demands despite longer preparation times.

Future Trends in Plate Technology

Future trends in plate technology emphasize the shift from traditional plates to digital plates, driven by advancements in high-resolution imaging and rapid processing capabilities. Digital plates offer enhanced efficiency, improved image quality, and scalability for diverse applications in medical and industrial fields. Your workflow can benefit from integration with AI-powered analysis tools, signaling a move towards fully automated, smart imaging solutions.

Digital plates vs traditional plates Infographic

libmatt.com

libmatt.com