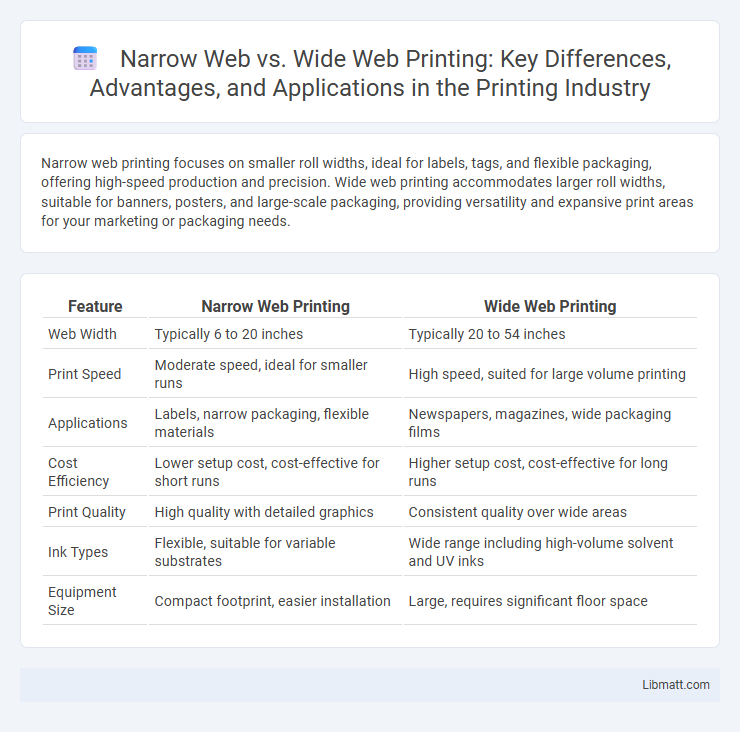

Narrow web printing focuses on smaller roll widths, ideal for labels, tags, and flexible packaging, offering high-speed production and precision. Wide web printing accommodates larger roll widths, suitable for banners, posters, and large-scale packaging, providing versatility and expansive print areas for your marketing or packaging needs.

Table of Comparison

| Feature | Narrow Web Printing | Wide Web Printing |

|---|---|---|

| Web Width | Typically 6 to 20 inches | Typically 20 to 54 inches |

| Print Speed | Moderate speed, ideal for smaller runs | High speed, suited for large volume printing |

| Applications | Labels, narrow packaging, flexible materials | Newspapers, magazines, wide packaging films |

| Cost Efficiency | Lower setup cost, cost-effective for short runs | Higher setup cost, cost-effective for long runs |

| Print Quality | High quality with detailed graphics | Consistent quality over wide areas |

| Ink Types | Flexible, suitable for variable substrates | Wide range including high-volume solvent and UV inks |

| Equipment Size | Compact footprint, easier installation | Large, requires significant floor space |

Introduction to Web Printing Technologies

Web printing technologies encompass processes that use continuous rolls of paper or other substrates for high-speed production. Narrow web printing specializes in labels, packaging, and flexible materials with widths typically below 12 inches, offering precision and efficiency in short-run or customized jobs. Wide web printing, exceeding 20 inches in width, caters to large-scale applications like banners, posters, and packaging, providing greater versatility for diverse media and higher volume output.

Defining Narrow Web Printing

Narrow web printing refers to the process of printing on web rolls that are typically less than 14 inches wide, making it ideal for labels, tags, and flexible packaging. This method offers high precision and efficiency for short to medium runs, supporting intricate designs with vibrant colors and fine details. Your choice of narrow web printing can enhance brand presentation through superior print quality and material versatility.

Understanding Wide Web Printing

Wide web printing uses large rolls of paper, typically 24 inches or wider, ideal for high-volume production like newspapers and packaging. This method enables faster printing speeds and greater flexibility in handling large-scale projects, reducing material waste and costs. Understanding wide web printing helps you choose the right process for large-format needs, balancing quality and efficiency effectively.

Key Differences Between Narrow and Wide Web Printing

Narrow web printing typically uses rolls of material that are 8 inches or less in width, ideal for producing labels, tags, and small packaging, while wide web printing handles rolls wider than 12 inches, suitable for large-format graphics and flexible packaging. Narrow web presses offer faster setup times and lower material costs, making them efficient for short to medium print runs with high-quality output, whereas wide web presses provide greater versatility for high-volume production and larger print areas. Your choice depends on the required print width, production volume, and application specificity, with narrow web excelling in precision and economical small-scale jobs, and wide web delivering scalability and broader design possibilities.

Materials and Substrate Compatibility

Narrow web printing excels in handling flexible substrates like films, foils, and labels, offering precise print quality ideal for packaging materials. Wide web printing supports a broader range of substrates, including paper, cardboard, and laminates, accommodating larger printing formats for banners and posters. Your choice depends on the material type and end-use application, ensuring optimal adhesion and durability for each substrate.

Print Quality and Resolution Considerations

Narrow web printing typically achieves higher print quality and resolution due to specialized label presses designed for fine detail and crisp images, ideal for small-format labels and intricate designs. Wide web printing, while capable of handling larger roll widths, often balances speed and volume over ultra-high resolution, making it suitable for larger graphics but less precise detail work. Choosing between the two depends on the need for sharpness and detail versus production efficiency and size requirements.

Production Speed and Efficiency

Narrow web printing offers higher production speed and efficiency due to its ability to handle continuous rolls of narrow label stock, reducing downtime for roll changes. Wide web printing, while capable of producing larger formats, often experiences slower speeds and more frequent adjustments, impacting overall efficiency. For high-volume, fast-turnaround jobs, narrow web printing maximizes throughput and minimizes material waste.

Cost Comparison: Narrow vs Wide Web Printing

Narrow web printing generally offers lower setup and material costs because it uses smaller rolls of substrate, making it ideal for short to medium runs and specialty labels. Wide web printing involves higher initial expenses due to larger press sizes and more ink usage but benefits large-volume production with reduced cost per unit. Your choice depends on balancing upfront investment against long-term efficiency based on print job volume and application.

Ideal Applications for Each Printing Method

Narrow web printing is ideal for high-quality labels, flexible packaging, and adhesive stickers, often used in food, beverage, and cosmetics industries due to its precision and cost-effectiveness for shorter runs. Wide web printing excels in producing larger items such as banners, packaging cartons, and vehicle wraps, providing efficiency and versatility for high-volume print jobs requiring broader media widths. Your choice depends on the print size, media type, and production volume to ensure optimal results and cost-efficiency.

Choosing the Right Printing Method for Your Business

Choosing the right printing method for your business depends on the type of products and volume requirements; narrow web printing excels in producing high-quality labels and flexible packaging with precision on rolls usually 8 to 20 inches wide. Wide web printing caters to larger formats such as posters, banners, and flexible packaging over 20 inches, ideal for businesses needing high-volume output and versatility. Assessing your product size, material, and run length will help determine whether narrow or wide web printing aligns with your operational efficiency and cost-effectiveness.

Narrow web vs wide web printing Infographic

libmatt.com

libmatt.com