Anti-set-off powder prevents ink from smudging by creating a protective barrier on freshly printed surfaces, ensuring clean and crisp prints. Infrared drying uses radiant heat to quickly cure inks and coatings, enhancing drying speed and overall print quality.

Table of Comparison

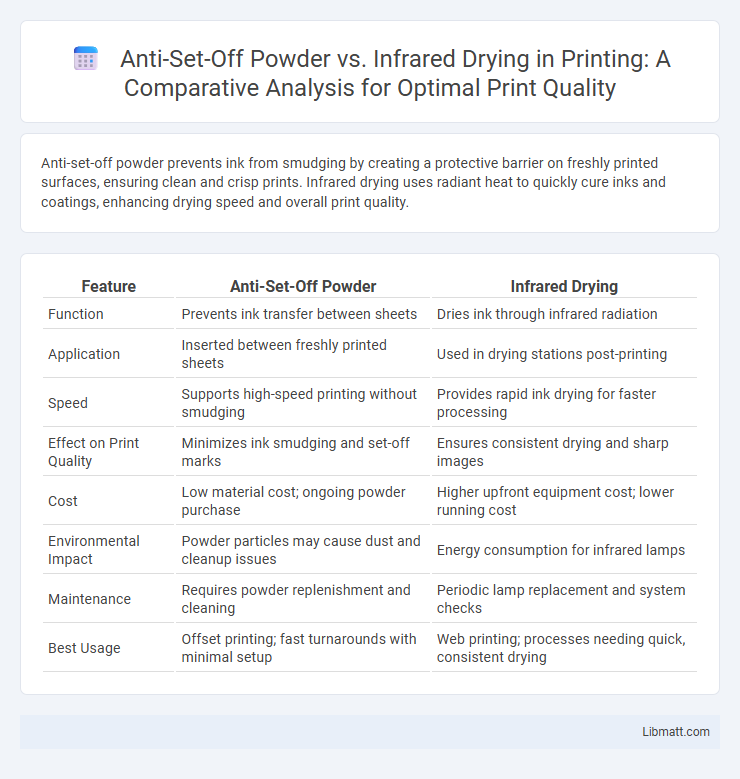

| Feature | Anti-Set-Off Powder | Infrared Drying |

|---|---|---|

| Function | Prevents ink transfer between sheets | Dries ink through infrared radiation |

| Application | Inserted between freshly printed sheets | Used in drying stations post-printing |

| Speed | Supports high-speed printing without smudging | Provides rapid ink drying for faster processing |

| Effect on Print Quality | Minimizes ink smudging and set-off marks | Ensures consistent drying and sharp images |

| Cost | Low material cost; ongoing powder purchase | Higher upfront equipment cost; lower running cost |

| Environmental Impact | Powder particles may cause dust and cleanup issues | Energy consumption for infrared lamps |

| Maintenance | Requires powder replenishment and cleaning | Periodic lamp replacement and system checks |

| Best Usage | Offset printing; fast turnarounds with minimal setup | Web printing; processes needing quick, consistent drying |

Introduction to Anti-Set-Off Powder and Infrared Drying

Anti-set-off powder is a fine, inert substance applied to freshly printed sheets to prevent ink transfer and smudging during stacking, ensuring high-quality print finishes and improved handling. Infrared drying utilizes infrared radiation to rapidly heat and cure inks or coatings on printed materials, enhancing production speed and drying efficiency without compromising print integrity. Both technologies optimize print production by minimizing defects and accelerating the drying process.

Understanding Set-Off Issues in Printing

Set-off issues in printing occur when wet ink transfers from one printed sheet to another, causing smudging and loss of print quality. Anti-set-off powder is applied as a fine layer of inert particles between sheets to prevent direct ink contact, ensuring crisp, clean prints. Infrared drying uses targeted heat to rapidly cure ink, reducing drying times and minimizing set-off risks by solidifying ink before stacking.

How Anti-Set-Off Powder Works

Anti-set-off powder consists of fine particles applied to freshly printed sheets to prevent ink from transferring during stacking and handling. The powder creates a microscopic barrier that separates sheets, allowing air to circulate and facilitating faster drying without interfering with ink adhesion. By using anti-set-off powder, you can maintain print quality while optimizing drying time in offset printing processes.

Infrared Drying Technology Explained

Infrared drying technology uses electromagnetic waves to penetrate materials and rapidly evaporate moisture, providing efficient and uniform drying compared to anti-set-off powders that prevent ink smudging on printed sheets. This method reduces drying time and energy consumption while minimizing material distortion, making it ideal for delicate or heat-sensitive substrates. Your production process benefits from infrared drying by achieving faster turnaround and superior finish quality without the residue concerns associated with powder usage.

Efficiency Comparison: Powder vs Infrared Drying

Anti-set-off powder offers efficient drying by absorbing excess ink quickly, preventing smudging in high-speed printing environments. Infrared drying uses radiant heat to cure inks rapidly, allowing faster drying times and enhanced print durability. While anti-set-off powder is cost-effective for offset presses, infrared drying provides superior efficiency in digital and specialty ink applications.

Impact on Print Quality and Consistency

Anti-set-off powder enhances print quality by preventing ink smudging and maintaining sharp image clarity, ensuring consistent results throughout large print runs. Infrared drying accelerates ink drying times, reducing production delays and minimizing the risk of ink transfer, which improves overall print consistency on various paper stocks. Combining anti-set-off powder with infrared drying creates a balanced approach that safeguards both ink stability and drying efficiency, resulting in superior print quality.

Environmental Considerations and Safety

Anti-set-off powder reduces ink smudging on printed sheets, minimizing the need for solvent-based cleaning agents and lowering volatile organic compound (VOC) emissions, contributing to a safer and more environmentally friendly printing process. Infrared drying accelerates ink curing through rapid heat application, but it consumes significant energy and may emit heat-related pollutants, requiring careful ventilation and safety measures to avoid operator exposure. Choosing between anti-set-off powder and infrared drying depends on balancing energy consumption, emission controls, and workplace safety protocols to optimize environmental impact.

Cost Analysis: Initial Investment and Operational Expenses

Anti-set-off powder requires a moderate initial investment primarily for purchasing powder applicators and storage equipment, while infrared drying systems demand a higher upfront cost due to advanced heating technology and control units. Operational expenses for anti-set-off powder include ongoing powder replenishment and maintenance of applicators, whereas infrared drying incurs energy costs that fluctuate based on drying intensity and frequency. Long-term cost efficiency favors infrared drying in high-volume operations due to reduced material waste and faster drying times, despite higher initial capital outlay.

Maintenance and Workflow Implications

Anti-set-off powder requires regular replenishment and cleaning to prevent clogging and residue buildup, impacting maintenance frequency and workflow efficiency. Infrared drying systems minimize downtime due to less frequent maintenance needs and faster drying times, helping your production line maintain steady output. Both methods influence operational procedures, but infrared drying often enhances workflow continuity through reduced manual intervention.

Choosing the Best Solution for Your Printing Needs

Anti-set-off powder prevents ink smudging by creating a fine barrier between printed sheets, ideal for high-speed offset printing where quick drying is essential. Infrared drying uses targeted heat to cure inks rapidly, offering precise control and efficiency for various ink types, including UV and solvent-based. Evaluating factors such as drying speed, ink type, production volume, and finish quality helps determine whether anti-set-off powder or infrared drying best suits your printing requirements.

anti-set-off powder vs infrared drying Infographic

libmatt.com

libmatt.com