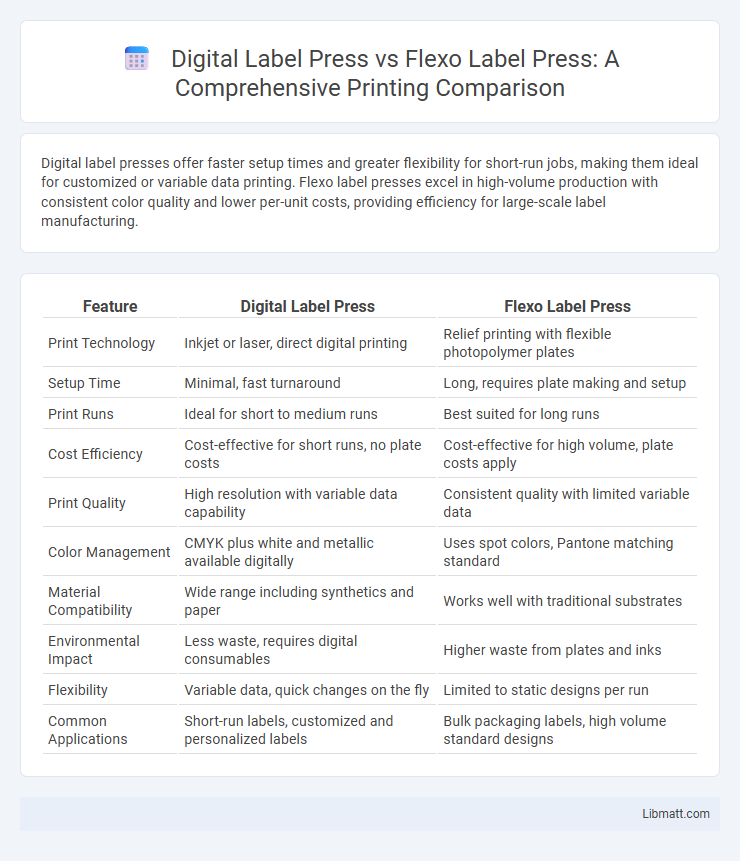

Digital label presses offer faster setup times and greater flexibility for short-run jobs, making them ideal for customized or variable data printing. Flexo label presses excel in high-volume production with consistent color quality and lower per-unit costs, providing efficiency for large-scale label manufacturing.

Table of Comparison

| Feature | Digital Label Press | Flexo Label Press |

|---|---|---|

| Print Technology | Inkjet or laser, direct digital printing | Relief printing with flexible photopolymer plates |

| Setup Time | Minimal, fast turnaround | Long, requires plate making and setup |

| Print Runs | Ideal for short to medium runs | Best suited for long runs |

| Cost Efficiency | Cost-effective for short runs, no plate costs | Cost-effective for high volume, plate costs apply |

| Print Quality | High resolution with variable data capability | Consistent quality with limited variable data |

| Color Management | CMYK plus white and metallic available digitally | Uses spot colors, Pantone matching standard |

| Material Compatibility | Wide range including synthetics and paper | Works well with traditional substrates |

| Environmental Impact | Less waste, requires digital consumables | Higher waste from plates and inks |

| Flexibility | Variable data, quick changes on the fly | Limited to static designs per run |

| Common Applications | Short-run labels, customized and personalized labels | Bulk packaging labels, high volume standard designs |

Introduction to Digital and Flexo Label Presses

Digital label presses use inkjet or laser technology to print directly from digital files, offering high-speed production and quick turnaround with minimal setup costs ideal for short runs and customization. Flexo label presses employ flexible relief plates and fast-drying inks, enabling high-volume printing with consistent quality, making them cost-effective for long runs and standard designs. Each press type caters to different production needs, with digital presses excelling in flexibility and speed, while flexo presses provide economy and durability in large-scale label manufacturing.

Overview of Digital Label Printing Technology

Digital label printing technology uses advanced inkjet or laser printers to produce high-quality, short-run labels with rapid turnaround times and minimal setup costs. Unlike flexo label presses, which rely on engraved plates for each color and are ideal for large-volume jobs, digital presses enable on-demand customization and variable data printing without the need for physical plates. Your choice between digital and flexo label printing depends on print run size, design complexity, and speed requirements.

Understanding Flexographic (Flexo) Label Printing

Flexographic (Flexo) label printing uses flexible relief plates and fast-drying inks, making it ideal for high-volume production of consistent, durable labels on various substrates like paper, film, and foil. Digital label presses offer quick turnaround times and customization capabilities without the need for plates, but flexo presses excel in efficiency and cost-effectiveness for long runs. Understanding flexo printing involves recognizing its strength in producing vibrant, high-quality labels with superior adhesion and resistance, especially for packaging applications.

Print Quality: Digital vs Flexo

Digital label presses deliver superior print quality with sharp details, vibrant colors, and precise gradients due to advanced inkjet or toner technologies that enable high-resolution output. Flexo label presses, while efficient for large-volume runs, often show limitations in color consistency and fine detail reproduction because of the flexible relief plates and limited ink control. For short runs or designs requiring intricate detail and quick turnaround, digital printing provides a distinct advantage in print quality over flexo technology.

Cost Comparison: Digital and Flexo Label Presses

Digital label presses typically have lower initial setup costs compared to flexo presses, which require expensive plates and longer preparation times. Your overall expenses with digital presses are often more predictable due to minimal waste and quick job changes, while flexo presses offer lower per-unit costs for large production runs but higher upfront investment. For short to medium runs, digital presses provide better cost efficiency, whereas flexo presses become more economical as volume scales.

Speed and Production Efficiency

Digital label presses offer faster setup times and enable on-demand printing, significantly reducing downtime compared to flexo label presses, which require longer plate preparation and make-ready processes. While flexo presses excel in high-volume production with consistent print quality and lower per-unit costs, digital presses provide superior speed for short runs and frequent design changes, enhancing overall production efficiency. Advances in digital technology continue to close the speed gap, making digital presses increasingly competitive for mid-to-large scale label printing projects.

Flexibility and Customization Options

Digital label presses offer superior flexibility with quick setup times and the ability to print variable data, making them ideal for short runs and customized labels. Flexo label presses excel in high-volume production efficiency but require significant setup and plate changes, limiting customization for each print run. Choosing between digital and flexo presses depends on balancing the need for flexibility and customization against production scale and cost efficiency.

Environmental Impact and Sustainability

Digital label presses generate less waste by eliminating the need for printing plates and enabling precise, on-demand printing, which reduces overproduction and excess inventory. Flexo label presses consume more energy and produce higher levels of chemical waste due to ink solvents and plate-making processes, contributing to a larger environmental footprint. Sustainable practices in digital presses include water-based inks and recyclable substrates, making them a greener choice compared to traditional flexo printing methods.

Application Suitability: Which Press for Which Job?

Digital label presses excel in short runs, variable data printing, and quick turnaround times, making them ideal for personalized labels, prototypes, and small batch productions. Flexo label presses are better suited for high-volume runs and consistent, long-term projects, offering cost efficiency and superior ink durability on various substrates. Understanding your specific application needs ensures you choose the press that delivers optimal quality and cost-effectiveness for your labeling job.

Choosing the Right Label Press for Your Business

Digital label presses offer superior flexibility and shorter turnaround times, making them ideal for businesses needing small to medium runs and customized labels with variable data. Flexo label presses excel in high-volume production with lower per-unit costs, delivering consistent quality for long print runs and simple color schemes. Your choice depends on balancing volume, budget, and design complexity to optimize label production efficiency and cost-effectiveness.

digital label press vs flexo label press Infographic

libmatt.com

libmatt.com