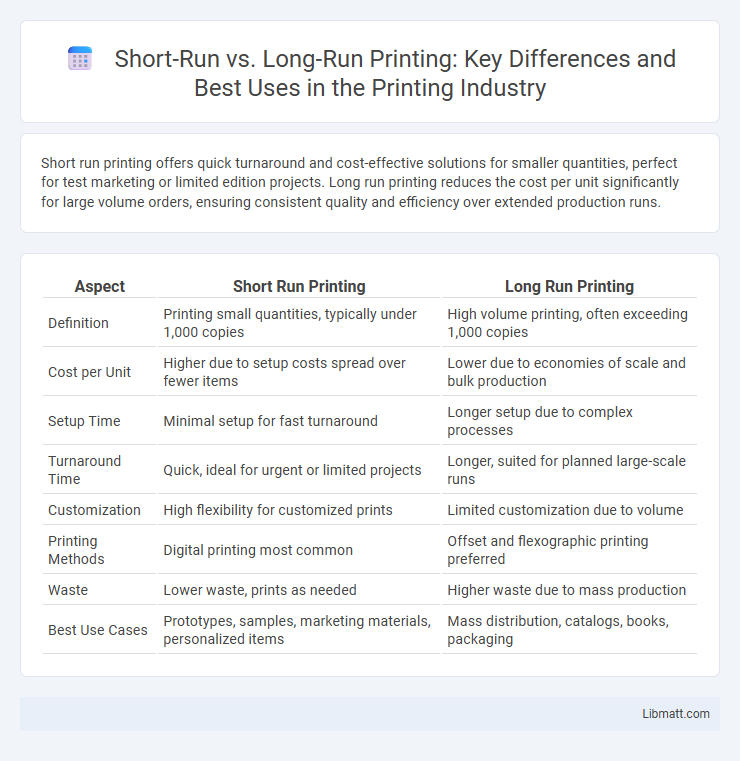

Short run printing offers quick turnaround and cost-effective solutions for smaller quantities, perfect for test marketing or limited edition projects. Long run printing reduces the cost per unit significantly for large volume orders, ensuring consistent quality and efficiency over extended production runs.

Table of Comparison

| Aspect | Short Run Printing | Long Run Printing |

|---|---|---|

| Definition | Printing small quantities, typically under 1,000 copies | High volume printing, often exceeding 1,000 copies |

| Cost per Unit | Higher due to setup costs spread over fewer items | Lower due to economies of scale and bulk production |

| Setup Time | Minimal setup for fast turnaround | Longer setup due to complex processes |

| Turnaround Time | Quick, ideal for urgent or limited projects | Longer, suited for planned large-scale runs |

| Customization | High flexibility for customized prints | Limited customization due to volume |

| Printing Methods | Digital printing most common | Offset and flexographic printing preferred |

| Waste | Lower waste, prints as needed | Higher waste due to mass production |

| Best Use Cases | Prototypes, samples, marketing materials, personalized items | Mass distribution, catalogs, books, packaging |

Introduction to Short Run and Long Run Printing

Short run printing involves producing a limited quantity of printed materials, typically ranging from a few copies to several hundred, ideal for customized, time-sensitive, or budget-conscious projects. Long run printing focuses on large volume production, often thousands or millions of copies, suitable for mass distribution and achieving lower unit costs through economies of scale. Both methods utilize distinct technologies and workflows to optimize quality, turnaround time, and cost efficiency based on project scope and demand.

Defining Short Run Printing

Short run printing refers to the production of a limited quantity of printed materials, typically ranging from a few copies to several hundred. This method utilizes digital printing technology, offering quick turnaround times and cost-effective solutions for small-scale projects. Your business benefits from flexible print runs without the need for large inventory or extended commitments.

Understanding Long Run Printing

Long run printing involves producing large quantities of materials, typically exceeding several thousand units, which reduces the cost per unit due to economies of scale. It is ideal for businesses seeking consistent, high-volume output with uniform quality over time. Understanding long run printing helps you optimize budget planning and ensure timely fulfillment of extensive marketing or production campaigns.

Key Differences Between Short Run and Long Run Printing

Short run printing involves producing a limited quantity of materials, ideal for customized or time-sensitive projects, while long run printing caters to large volume orders with lower per-unit costs. Short run printing offers faster turnaround times and flexibility, whereas long run printing benefits from economies of scale and consistency in color and quality. Understanding these key differences helps you choose the right printing approach based on budget, timeline, and project goals.

Cost Analysis: Short Run vs Long Run Printing

Short run printing generally incurs higher cost per unit due to setup fees and limited economies of scale, making it ideal for small quantities and tight budgets. Long run printing reduces the cost per unit significantly as fixed setup expenses are spread over a larger volume, benefiting large orders and ongoing campaigns. Evaluating print volume, turnaround time, and budget constraints is crucial to determine the most cost-effective printing solution.

Turnaround Time and Flexibility Factors

Short run printing offers faster turnaround times due to minimal setup requirements and digital printing technology, making it ideal for urgent projects and quick adjustments. Long run printing involves extended production cycles with traditional offset presses, resulting in longer lead times but lower per-unit costs for high-volume orders. Flexibility in short run printing supports frequent design changes and customization, whereas long run printing is less adaptable once the production process begins.

Quality and Customization in Both Printing Methods

Short run printing offers high-quality results with exceptional customization, ideal for limited quantities where personalized designs and quick turnaround are essential. Long run printing excels in maintaining consistent quality across large volumes, providing cost-effective solutions for standardized prints with less variation. Your choice depends on whether you prioritize flexibility and bespoke options or uniformity and scalability.

Choosing the Right Printing Option for Your Project

Short run printing offers cost-effective solutions for smaller quantities, perfect for test marketing or limited editions, making it ideal when you need quick turnaround and customization. Long run printing becomes more economical for large volume orders, providing consistent quality and lower cost per unit, which suits projects with high distribution demands. Understanding your project's scale, budget, and timeline helps you select the most efficient printing option tailored to your specific needs.

Industry Applications: When to Use Short or Long Run Printing

Short run printing is ideal for prototyping, seasonal promotions, customized marketing materials, and limited edition products where quick turnaround and cost efficiency for small quantities matter most. Long run printing suits high-volume needs such as mass production of packaging, bulk catalogs, and large-scale direct mail campaigns, benefiting from economies of scale and lower per-unit costs. Industries like retail, publishing, and manufacturing choose short runs for agile marketing, while pharmaceuticals, consumer goods, and automotive sectors rely on long run printing for consistent brand messaging and supply chain demands.

Future Trends in Printing: Adapting to Market Demands

Future trends in printing emphasize the growing demand for short run printing due to its flexibility and cost-effectiveness in meeting personalized and small-batch orders. Long run printing continues to evolve with advancements in automation and sustainable practices to serve bulk production efficiently. Integrating digital technologies and eco-friendly materials allows businesses to adapt swiftly to market demands while maintaining high-quality output.

Short Run vs Long Run Printing Infographic

libmatt.com

libmatt.com