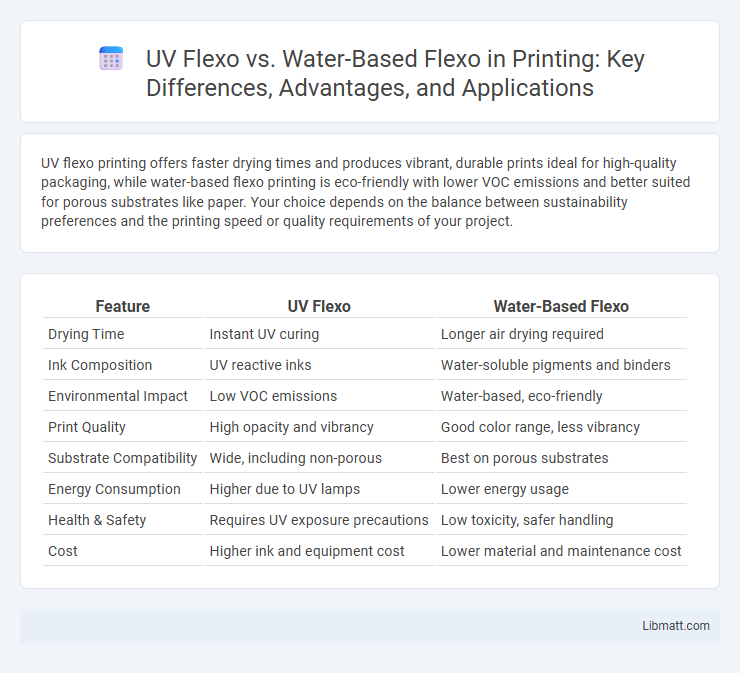

UV flexo printing offers faster drying times and produces vibrant, durable prints ideal for high-quality packaging, while water-based flexo printing is eco-friendly with lower VOC emissions and better suited for porous substrates like paper. Your choice depends on the balance between sustainability preferences and the printing speed or quality requirements of your project.

Table of Comparison

| Feature | UV Flexo | Water-Based Flexo |

|---|---|---|

| Drying Time | Instant UV curing | Longer air drying required |

| Ink Composition | UV reactive inks | Water-soluble pigments and binders |

| Environmental Impact | Low VOC emissions | Water-based, eco-friendly |

| Print Quality | High opacity and vibrancy | Good color range, less vibrancy |

| Substrate Compatibility | Wide, including non-porous | Best on porous substrates |

| Energy Consumption | Higher due to UV lamps | Lower energy usage |

| Health & Safety | Requires UV exposure precautions | Low toxicity, safer handling |

| Cost | Higher ink and equipment cost | Lower material and maintenance cost |

Introduction to Flexographic Printing Techniques

UV flexo printing uses ultraviolet light to cure inks instantly, providing faster drying times and sharper image quality compared to water-based flexo, which relies on evaporation for ink drying. Water-based flexo inks are eco-friendly, offering lower VOC emissions and easier cleanup, making them suitable for sustainable packaging solutions. Your choice between UV and water-based flexo depends on factors like substrate compatibility, production speed, and environmental considerations.

Overview of UV Flexo Inks

UV flexo inks cure instantly under ultraviolet light, providing rapid drying and superior print quality on various substrates. These inks offer high resistance to scratching, chemicals, and fading, making them ideal for packaging and labels requiring durability. Your choice of UV flexo inks ensures vibrant colors and enhanced production efficiency compared to traditional water-based flexo options.

Overview of Water-Based Flexo Inks

Water-based flexo inks use water as the primary solvent, making them eco-friendly and low in volatile organic compounds (VOCs), which improves air quality and worker safety. These inks provide vibrant colors and good adhesion on a variety of substrates, especially porous materials like paper and corrugated board, with fast drying times through evaporation. The formulation supports easy cleanup with water, reducing solvent handling and disposal costs compared to UV flexo inks that cure via ultraviolet light.

Print Quality Comparison: UV vs Water-Based Flexo

UV flexo printing delivers higher print quality with sharper details, vibrant colors, and better opacity due to instant curing and less ink absorption. Water-based flexo printing often shows softer images with slight color variation and slower drying times, which can affect precision on porous substrates. UV inks provide superior durability and resistance to fading, making them ideal for packaging requiring long shelf life.

Drying and Curing Processes in Flexography

UV flexo printing utilizes ultraviolet light to instantly cure inks through photopolymerization, resulting in faster drying times and enhanced print durability. Water-based flexo relies on evaporation to dry inks, which requires higher temperatures and longer curing periods, impacting production speed and energy consumption. The choice between UV and water-based flexo significantly affects the drying mechanism, environmental considerations, and substrate compatibility in flexographic printing processes.

Substrate Compatibility: UV Flexo vs Water-Based Flexo

UV flexo printing excels on a wider range of substrates, including non-porous materials like plastics, foils, and coated papers, due to the instant curing of UV inks. Water-based flexo inks perform best on porous substrates such as paper and cardboard, offering strong adhesion and vibrant color without compromising recyclability. Substrate compatibility directly influences print durability and environmental considerations in packaging and labeling applications.

Environmental Impact and Regulatory Considerations

UV flexo printing uses ultraviolet light to cure inks instantly, reducing volatile organic compound (VOC) emissions and minimizing hazardous waste compared to water-based flexo, which relies on water as a solvent but can emit VOCs during drying. Regulatory agencies increasingly favor UV flexo for its lower environmental footprint, stricter air quality standards, and compliance with VOC reduction policies in regions like the EU and California. The disposal and recycling requirements for UV inks demand adherence to specific hazardous waste protocols, while water-based inks generally allow easier cleanup but may require monitoring for water discharge regulations.

Cost Analysis: UV Flexo vs Water-Based Flexo

UV flexo printing usually involves higher initial equipment costs due to specialized UV curing units and ink formulations, but offers faster drying times that can improve overall production efficiency. Water-based flexo tends to have lower upfront expenses and simpler ink handling but may incur higher ongoing costs related to longer drying processes and increased energy consumption. Your choice between UV and water-based flexo should consider both the short-term investment and long-term operational costs to optimize budget and workflow.

Application Suitability for Different Industries

UV flexo printing excels in industries requiring fast curing and high durability, such as electronics, automotive, and food packaging due to its resistance to chemicals and moisture. Water-based flexo is preferred in the packaging and label sectors valuing environmental sustainability and systems compatible with porous surfaces like paper and cardboard. Your choice depends on the specific industry's needs for print quality, substrate compatibility, and regulatory compliance.

Future Trends in Flexographic Printing Technologies

Future trends in flexographic printing technologies emphasize increased adoption of UV flexo due to its faster curing times and higher print quality, which enhances production efficiency and color vibrancy. Water-based flexo continues to develop with advancements in eco-friendly inks and improved drying systems, meeting stringent environmental regulations worldwide. Innovations in hybrid printing systems that combine UV and water-based flexographic methods are emerging to maximize substrate versatility and sustainability.

UV flexo vs water-based flexo Infographic

libmatt.com

libmatt.com