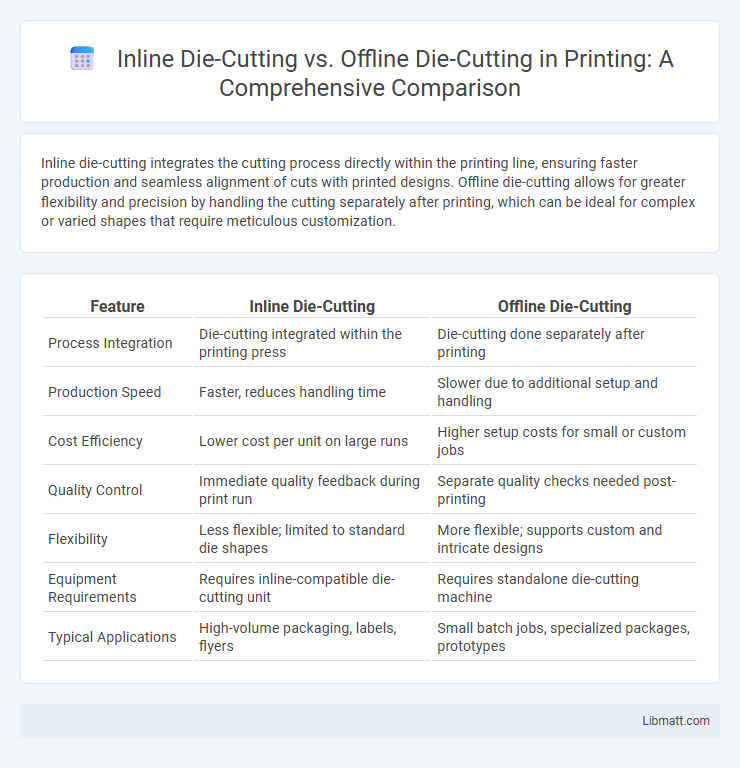

Inline die-cutting integrates the cutting process directly within the printing line, ensuring faster production and seamless alignment of cuts with printed designs. Offline die-cutting allows for greater flexibility and precision by handling the cutting separately after printing, which can be ideal for complex or varied shapes that require meticulous customization.

Table of Comparison

| Feature | Inline Die-Cutting | Offline Die-Cutting |

|---|---|---|

| Process Integration | Die-cutting integrated within the printing press | Die-cutting done separately after printing |

| Production Speed | Faster, reduces handling time | Slower due to additional setup and handling |

| Cost Efficiency | Lower cost per unit on large runs | Higher setup costs for small or custom jobs |

| Quality Control | Immediate quality feedback during print run | Separate quality checks needed post-printing |

| Flexibility | Less flexible; limited to standard die shapes | More flexible; supports custom and intricate designs |

| Equipment Requirements | Requires inline-compatible die-cutting unit | Requires standalone die-cutting machine |

| Typical Applications | High-volume packaging, labels, flyers | Small batch jobs, specialized packages, prototypes |

Introduction to Die-Cutting Methods

Inline die-cutting integrates the die-cutting process directly into the printing press, enabling faster production and seamless workflow by eliminating the need for separate handling. Offline die-cutting occurs after printing on a standalone machine, offering greater flexibility for complex cuts and smaller production runs. Choosing between inline and offline die-cutting depends on factors such as production speed, complexity of design, and volume requirements.

What is Inline Die-Cutting?

Inline die-cutting integrates the die-cutting process directly into the printing press, allowing simultaneous printing and cutting of materials such as labels or packaging. This method enhances production speed, accuracy, and reduces labor costs by eliminating separate handling steps. Inline die-cutting is ideal for high-volume runs requiring precise registration and minimal turnaround time.

What is Offline Die-Cutting?

Offline die-cutting is a production process where the die-cutting operation occurs separately from the main printing or converting line, using standalone machines designed for precise cutting of materials like paper, cardboard, or labels. This method allows for greater flexibility in handling diverse substrates and sizes, accommodating complex die shapes that may be challenging to integrate inline. Offline die-cutting is ideal for short runs, prototyping, or finishing tasks that require specialized tooling or detailed cuts beyond the capabilities of inline systems.

Key Differences: Inline vs Offline Die-Cutting

Inline die-cutting integrates directly with the printing process, allowing for faster production and reduced material handling, resulting in higher efficiency and lower costs. Offline die-cutting operates as a separate step after printing, offering greater flexibility for complex designs and specialized finishes but requiring additional time and labor. Choosing between inline and offline die-cutting depends on production volume, design complexity, and budget considerations.

Production Speed and Efficiency Comparison

Inline die-cutting integrates the die-cutting process directly into the printing line, significantly enhancing production speed by eliminating the need for separate handling and transfer between machines. This seamless workflow reduces downtime and material waste, leading to higher overall efficiency and faster turnaround times. In contrast, offline die-cutting requires moving printed sheets to a separate press, increasing production time and labor costs due to additional setup and alignment steps.

Cost Implications of Inline and Offline Approaches

Inline die-cutting integrates the cutting process directly within the printing press, reducing labor and setup costs by streamlining production, which often leads to lower overall expenses for high-volume, continuous runs. Offline die-cutting involves a separate machine for cutting, increasing handling and setup time, which can result in higher costs due to additional labor and slower turnaround but offers greater flexibility for smaller or varied jobs. Choosing between inline and offline methods depends on your production scale and budget, with inline being more cost-effective for large runs and offline preferred for customization or limited quantities.

Quality and Precision: Evaluating Results

Inline die-cutting integrates cutting processes directly within the production line, ensuring higher consistency and precision due to real-time adjustments and minimal material handling. Offline die-cutting, performed separately after printing, can lead to slight variations in alignment and quality due to repositioning and additional handling steps. Evaluating results shows that inline die-cutting generally delivers superior quality and tighter tolerances, making it ideal for high-volume, detail-sensitive applications.

Flexibility in Design and Customization

Inline die-cutting offers greater flexibility in design and customization by seamlessly integrating the cutting process directly into the printing workflow, enabling faster adjustments and consistent quality control. Offline die-cutting allows for more complex and intricate designs as it operates independently from printing, providing enhanced versatility for specialty projects. Your choice depends on the need for rapid production versus detailed customization.

Application Scenarios: When to Choose Each Method

Inline die-cutting is ideal for high-volume production where speed and integration with printing processes are essential, such as packaging and label manufacturing. Offline die-cutting suits smaller runs, prototyping, or projects requiring intricate cuts and greater flexibility, often seen in specialty printing and custom jobs. Your choice depends on throughput demands, complexity of the design, and the level of process control needed.

Conclusion: Selecting the Right Die-Cutting Solution

Selecting the right die-cutting solution depends on production volume, budget, and workflow integration. Inline die-cutting offers seamless integration with printing processes, ideal for high-speed, large-scale operations requiring efficiency and consistency. Offline die-cutting provides flexibility and precision for smaller runs or specialized designs, making it suitable for businesses prioritizing customization and quality control.

Inline die-cutting vs offline die-cutting Infographic

libmatt.com

libmatt.com