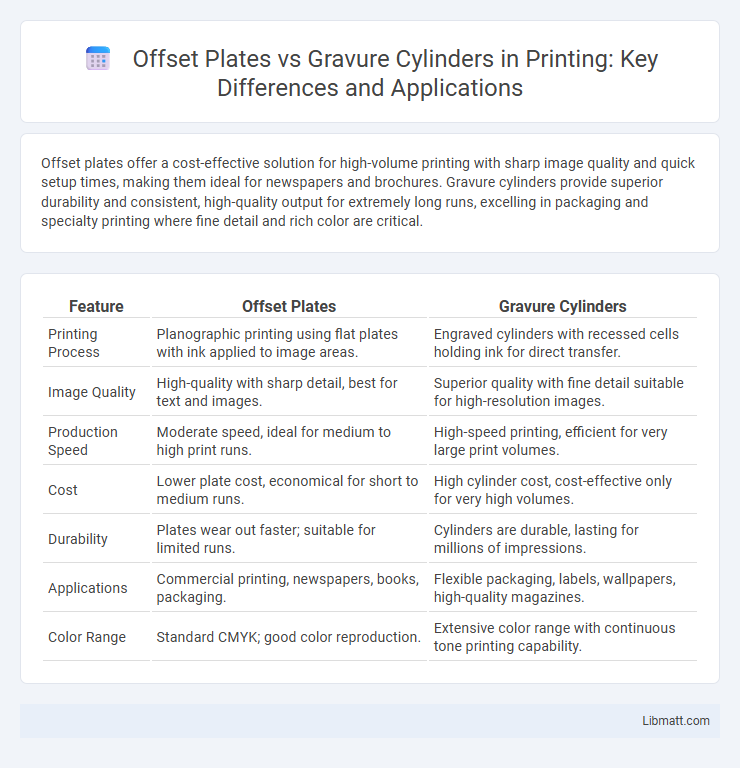

Offset plates offer a cost-effective solution for high-volume printing with sharp image quality and quick setup times, making them ideal for newspapers and brochures. Gravure cylinders provide superior durability and consistent, high-quality output for extremely long runs, excelling in packaging and specialty printing where fine detail and rich color are critical.

Table of Comparison

| Feature | Offset Plates | Gravure Cylinders |

|---|---|---|

| Printing Process | Planographic printing using flat plates with ink applied to image areas. | Engraved cylinders with recessed cells holding ink for direct transfer. |

| Image Quality | High-quality with sharp detail, best for text and images. | Superior quality with fine detail suitable for high-resolution images. |

| Production Speed | Moderate speed, ideal for medium to high print runs. | High-speed printing, efficient for very large print volumes. |

| Cost | Lower plate cost, economical for short to medium runs. | High cylinder cost, cost-effective only for very high volumes. |

| Durability | Plates wear out faster; suitable for limited runs. | Cylinders are durable, lasting for millions of impressions. |

| Applications | Commercial printing, newspapers, books, packaging. | Flexible packaging, labels, wallpapers, high-quality magazines. |

| Color Range | Standard CMYK; good color reproduction. | Extensive color range with continuous tone printing capability. |

Introduction to Offset Plates and Gravure Cylinders

Offset plates and gravure cylinders serve distinct roles in printing technology, each optimized for specific types of print jobs. Offset plates are flat and use a process where ink is transferred from the plate to a rubber blanket before reaching the paper, allowing high-quality image reproduction on various surfaces. Gravure cylinders are engraved with tiny cells that hold the ink, enabling precise, high-speed printing ideal for long runs and detailed images; your choice depends on the print volume and quality requirements.

Key Differences Between Offset and Gravure Printing

Offset plates utilize a flat surface where ink transfers from a plate to a rubber blanket and then onto paper, delivering sharp and consistent images ideal for short to medium print runs. Gravure cylinders feature engraved cells that hold ink, enabling high-quality, continuous-tone printing suited for long runs and fine detail reproduction. Your choice depends on production volume, image quality needs, and cost efficiency.

Material Composition: Plates vs Cylinders

Offset plates are typically made from aluminum or polyester, coated with a photosensitive polymer that reacts to light exposure for image creation. Gravure cylinders consist of a steel or copper base, often copper-plated and then chrome-plated for durability and precision engraving of image cells. The distinct material compositions influence the printing quality and longevity, with offset plates favoring cost-effective, high-volume runs and gravure cylinders enabling ultra-fine image detail for long press runs.

Image Transfer Processes Compared

Offset plates use a planographic process where ink adheres to the image area and water repels the non-image area, transferring ink first to a rubber blanket and then to paper, ensuring high-quality, flexible printing ideal for varied substrates. Gravure cylinders employ an intaglio process with engraved cells holding ink that directly transfers to the substrate, delivering consistent, high-resolution images and vibrant colors suited for long print runs. The offset process excels in sharpness and fine detail on textured surfaces, while gravure offers superior ink density and durability for continuous, high-volume production.

Printing Quality and Resolution

Offset plates deliver high printing quality with sharp, crisp images ideal for detailed text and graphics, thanks to their ability to produce fine lines and smooth gradients. Gravure cylinders excel in resolution by engraving microscopic cells, which enables exceptional detail and vibrant color reproduction, especially in long-run printing jobs. Your choice between the two depends on the desired print resolution and image sharpness, with offset favoring precision and gravure excelling in rich, continuous-tone quality.

Cost Analysis: Production and Maintenance

Offset plates typically incur lower initial production costs compared to gravure cylinders, making them more cost-effective for short to medium print runs. Gravure cylinders involve higher upfront expenses due to intricate engraving processes but offer longer durability and consistent print quality, reducing maintenance frequency over time. Maintenance costs for offset plates are generally higher in the long run, as plates require frequent replacement and cleaning, whereas gravure cylinders demand specialized upkeep but benefit from extended lifecycle usage.

Durability and Lifespan

Offset plates typically offer moderate durability with a lifespan suited for short to medium print runs of up to 100,000 impressions, making them cost-effective for diverse printing needs. Gravure cylinders, constructed from engraved metal and coated for enhanced protection, provide exceptional durability and can sustain high-volume production exceeding 1 million impressions without significant quality degradation. The superior wear resistance of gravure cylinders ensures consistent image quality over long runs, whereas offset plates require more frequent replacement due to abrasion and chemical wear.

Prepress Preparation and Workflow

Offset plates require a precise prepress preparation process involving imaging with laser platesetters and chemical or thermal development to create the image area, ensuring accurate ink transfer during printing. Gravure cylinders are prepared through direct engraving or etching, often using laser technology, which creates microscopic cells that hold ink and deliver consistent quality in high-volume runs. The offset workflow emphasizes plate mounting and press calibration, while gravure demands meticulous cylinder inspection and maintenance for optimal print fidelity.

Typical Applications in the Printing Industry

Offset plates are commonly used in commercial printing for newspapers, brochures, and packaging due to their high-quality image reproduction and cost-effectiveness for medium to large print runs. Gravure cylinders dominate in high-volume printing applications such as magazines, labels, and flexible packaging, where fine detail and consistent print quality are essential. Your choice between offset plates and gravure cylinders ultimately depends on the specific production volume, image detail requirements, and substrate compatibility for your printing project.

Choosing the Right Method for Your Project

Choosing between offset plates and gravure cylinders depends on project requirements such as print volume, image quality, and budget. Offset plates offer high-quality prints with faster turnaround times, ideal for medium to large runs with detailed images. Gravure cylinders deliver superior color consistency and durability suited for very high-volume printing, making them cost-effective for long production runs with fine detail.

Offset plates vs gravure cylinders Infographic

libmatt.com

libmatt.com