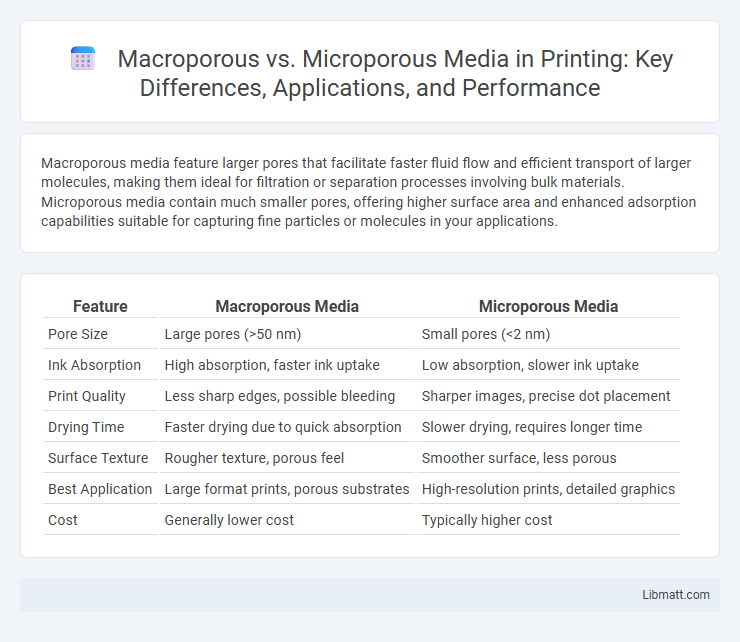

Macroporous media feature larger pores that facilitate faster fluid flow and efficient transport of larger molecules, making them ideal for filtration or separation processes involving bulk materials. Microporous media contain much smaller pores, offering higher surface area and enhanced adsorption capabilities suitable for capturing fine particles or molecules in your applications.

Table of Comparison

| Feature | Macroporous Media | Microporous Media |

|---|---|---|

| Pore Size | Large pores (>50 nm) | Small pores (<2 nm) |

| Ink Absorption | High absorption, faster ink uptake | Low absorption, slower ink uptake |

| Print Quality | Less sharp edges, possible bleeding | Sharper images, precise dot placement |

| Drying Time | Faster drying due to quick absorption | Slower drying, requires longer time |

| Surface Texture | Rougher texture, porous feel | Smoother surface, less porous |

| Best Application | Large format prints, porous substrates | High-resolution prints, detailed graphics |

| Cost | Generally lower cost | Typically higher cost |

Introduction to Porous Media

Porous media are materials containing interconnected voids or pores that allow fluids or gases to pass through, classified primarily into macroporous and microporous types based on pore size. Macroporous media feature pore diameters typically greater than 50 nanometers, facilitating higher permeability and faster fluid flow, essential in applications like filtration and catalysis. Microporous media possess pore sizes less than 2 nanometers, offering high surface area and selective adsorption capabilities crucial for gas separation and molecular sieving.

Defining Macroporous Media

Macroporous media are characterized by pore sizes typically larger than 50 nanometers, enabling enhanced flow rates and efficient mass transfer in applications like filtration and chromatography. These large pores facilitate the rapid transport of fluids and larger molecules, making macroporous materials ideal for processes requiring minimal resistance and high permeability. The structural attributes of macroporous media distinguish them from microporous counterparts, which contain much smaller pores below 2 nanometers, primarily affecting adsorption and separation at the molecular level.

Defining Microporous Media

Microporous media consist of materials with pore sizes typically less than 2 nanometers, enabling high surface area and selective molecular sieving properties. This fine porosity allows your filtration or separation processes to target very small particles or molecules, making microporous media ideal for applications like gas separation, catalysis, and fine filtration. Understanding the precise pore structure and distribution is crucial for optimizing performance in these highly specialized systems.

Key Differences Between Macroporous and Microporous Media

Macroporous media contain larger pores, typically greater than 50 nanometers, allowing for enhanced fluid flow and the passage of bigger molecules or particles. In contrast, microporous media have pore sizes smaller than 2 nanometers, offering higher surface area for adsorption but limiting permeability and fluid transport. These differences make macroporous materials ideal for filtration and support structures, while microporous materials excel in applications requiring selective adsorption and high surface interaction such as catalysis and gas separation.

Material Composition and Structure

Macroporous media consist of larger pores, typically greater than 50 nanometers, allowing high flow rates and enhanced permeation due to interconnected voids often made from polymers, ceramics, or metals. Microporous media feature pore sizes below 2 nanometers, providing selective permeability and high surface area, commonly composed of materials like activated carbon, zeolites, or microporous polymers. Your choice between these media depends on the required filtration precision and material compatibility for your specific application.

Surface Area and Pore Size Distribution

Macroporous media feature larger pore sizes typically greater than 50 nanometers, which allows for easier fluid flow but results in lower surface area compared to microporous media. Microporous media contain pores smaller than 2 nanometers, providing a significantly higher surface area and enhanced adsorption capacity, ideal for applications requiring fine filtration or chemical reactions. Your choice between these media depends on whether maximizing surface area or optimizing flow rate through pore size distribution is more critical for the specific application.

Applications of Macroporous Media

Macroporous media, characterized by larger pore sizes typically greater than 50 nanometers, are extensively used in applications such as filtration, chromatography, and catalysis where high flow rates and low pressure drops are essential. These materials facilitate rapid mass transfer and are often employed in water treatment, bioreactor supports, and gas separation processes. Their structural properties enable efficient adsorption and separation of large molecules and suspended particles, making them ideal for industrial and environmental applications.

Applications of Microporous Media

Microporous media are widely used in gas separation, filtration, and catalyst supports due to their high surface area and selective permeability. Their pore sizes, typically less than 2 nanometers, enable precise molecular sieving, making them ideal for applications in air purification, water treatment, and chemical processing. These materials are critical in industries requiring high-efficiency separation, such as petrochemical refining and environmental engineering.

Performance Considerations: Filtration and Adsorption

Macroporous media provide superior filtration capabilities due to larger pore sizes that efficiently trap suspended solids and particulates, making them ideal for processes requiring high flow rates and minimal pressure drop. Microporous media excel in adsorption performance by offering a high surface area in small pores that effectively capture dissolved contaminants and molecules at the molecular level. Selecting between macroporous and microporous media depends on the targeted application, balancing filtration efficiency against adsorption capacity for optimal contaminant removal.

Choosing the Right Media for Your Application

Choosing the right media for your application depends on the particle size and flow rate requirements, with macroporous media offering larger pores for high flow rates and rapid mass transfer, while microporous media provide smaller pores ideal for selective filtration and adsorption of fine particles or molecules. Macroporous media is suitable for applications needing minimal pressure drop and enhanced throughput, such as wastewater treatment or chromatography with large biomolecules. Your selection should consider the specific separation goals, media surface area, and compatibility with the target substances to optimize performance and efficiency.

Macroporous vs Microporous Media Infographic

libmatt.com

libmatt.com