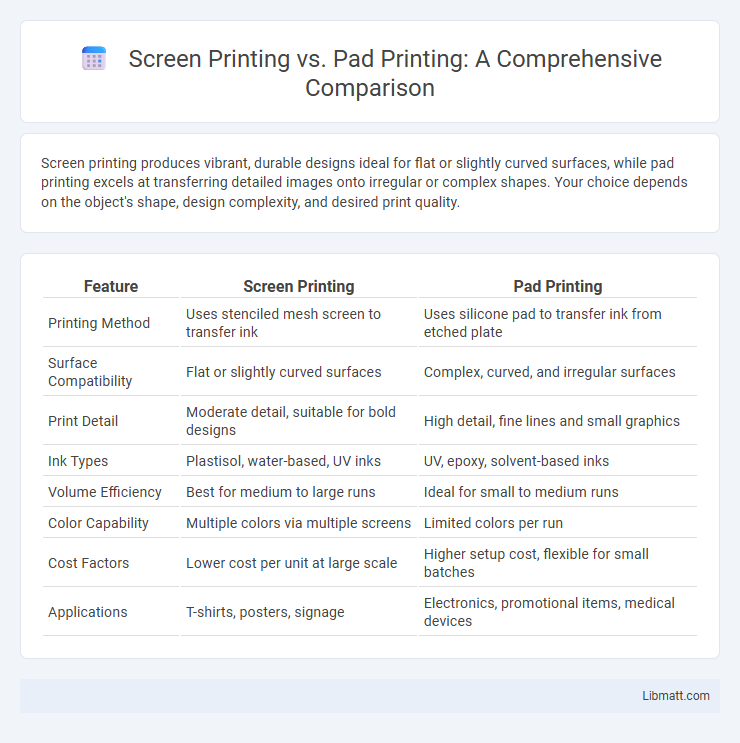

Screen printing produces vibrant, durable designs ideal for flat or slightly curved surfaces, while pad printing excels at transferring detailed images onto irregular or complex shapes. Your choice depends on the object's shape, design complexity, and desired print quality.

Table of Comparison

| Feature | Screen Printing | Pad Printing |

|---|---|---|

| Printing Method | Uses stenciled mesh screen to transfer ink | Uses silicone pad to transfer ink from etched plate |

| Surface Compatibility | Flat or slightly curved surfaces | Complex, curved, and irregular surfaces |

| Print Detail | Moderate detail, suitable for bold designs | High detail, fine lines and small graphics |

| Ink Types | Plastisol, water-based, UV inks | UV, epoxy, solvent-based inks |

| Volume Efficiency | Best for medium to large runs | Ideal for small to medium runs |

| Color Capability | Multiple colors via multiple screens | Limited colors per run |

| Cost Factors | Lower cost per unit at large scale | Higher setup cost, flexible for small batches |

| Applications | T-shirts, posters, signage | Electronics, promotional items, medical devices |

Introduction to Printing Techniques

Screen printing employs a mesh stencil to transfer ink onto flat or slightly curved surfaces, making it ideal for textiles, posters, and signage. Pad printing uses a silicone pad to pick up ink from an etched plate and transfer it onto irregular or three-dimensional objects, commonly used for promotional products, electronics, and medical devices. Both techniques offer distinct advantages based on surface type, print complexity, and production volume.

Overview of Screen Printing

Screen printing is a versatile printing technique that uses a mesh screen to transfer ink onto a substrate, making it ideal for producing bold and vibrant designs on various materials such as textiles, plastics, and paper. This method excels in high-volume production runs due to its durability and ability to create thick layers of ink, resulting in long-lasting prints with excellent color saturation. Understanding the advantages of screen printing can help you choose the best option for projects requiring detailed, vibrant graphics and durable finishes.

Overview of Pad Printing

Pad printing is a versatile printing technique that transfers 2D images onto 3D objects using a silicone pad, enabling high-precision decoration on irregular surfaces. It excels in printing on small, curved, or textured items such as electronics, medical devices, and promotional products, where screen printing may be limited. The process uses a recessed etched plate and specialized inks, allowing for fine details and multiple colors with minimal setup time.

Materials and Substrates Compatibility

Screen printing excels with flat, rigid materials like textiles, paper, glass, and metal, offering vibrant, durable prints on large surfaces. Pad printing adapts seamlessly to irregular, curved, or textured substrates such as plastic, ceramics, and electronic components, ensuring precise ink transfer in hard-to-reach areas. Your choice between these methods depends largely on the shape, texture, and material of the item you want to print on.

Print Quality and Detail Comparison

Screen printing offers vibrant colors and thick ink layers ideal for bold designs, but struggles with fine details compared to pad printing. Pad printing excels in precision, allowing intricate patterns and delicate lines on irregular or small surfaces, ensuring high-definition prints. If your project demands detailed imagery on complex shapes, pad printing provides superior quality and accuracy over screen printing.

Speed and Efficiency

Screen printing offers high speed and efficiency for large production runs, delivering consistent prints quickly on flat or slightly curved surfaces. Pad printing excels in printing on irregular, complex, or small objects with precision but generally operates at a slower pace than screen printing. Your choice depends on production volume and the shape of the items being printed.

Cost Analysis

Screen printing generally offers lower costs for large production runs due to its efficient ink application and faster setup times, making it ideal for bulk orders. Pad printing involves higher per-unit costs but excels in printing on irregular or curved surfaces with precision, often resulting in increased expenses for complex designs or small batches. Your choice between these methods should consider the balance between initial setup costs and the volume of items to achieve the most cost-effective outcome.

Durability and Longevity of Prints

Screen printing offers superior durability with thick ink layers that resist fading and wear, making it ideal for long-lasting designs on textiles and promotional products. Pad printing, while excellent for detailed and intricate prints, produces thinner ink deposits that may wear faster on high-friction surfaces. Choosing the right method depends on your product's usage and desired print longevity to ensure prints remain vibrant and intact over time.

Common Applications and Industries

Screen printing excels in producing vibrant, large graphics on textiles, posters, and promotional merchandise, making it popular in the apparel, advertising, and packaging industries. Pad printing suits intricate designs on irregular or small surfaces such as electronics, medical devices, and automotive parts, commonly utilized in consumer electronics, healthcare, and industrial manufacturing sectors. Both techniques serve diverse markets by adapting to different material surfaces and design complexities.

Choosing the Right Printing Method

Choosing the right printing method depends on your project requirements, such as surface type, print complexity, and volume. Screen printing excels in producing vibrant, durable designs on flat or slightly curved surfaces, while pad printing is ideal for detailed images on irregular or small objects. Your decision should consider factors like color range, cost-effectiveness for bulk orders, and the intricacy of the artwork.

Screen printing vs pad printing Infographic

libmatt.com

libmatt.com