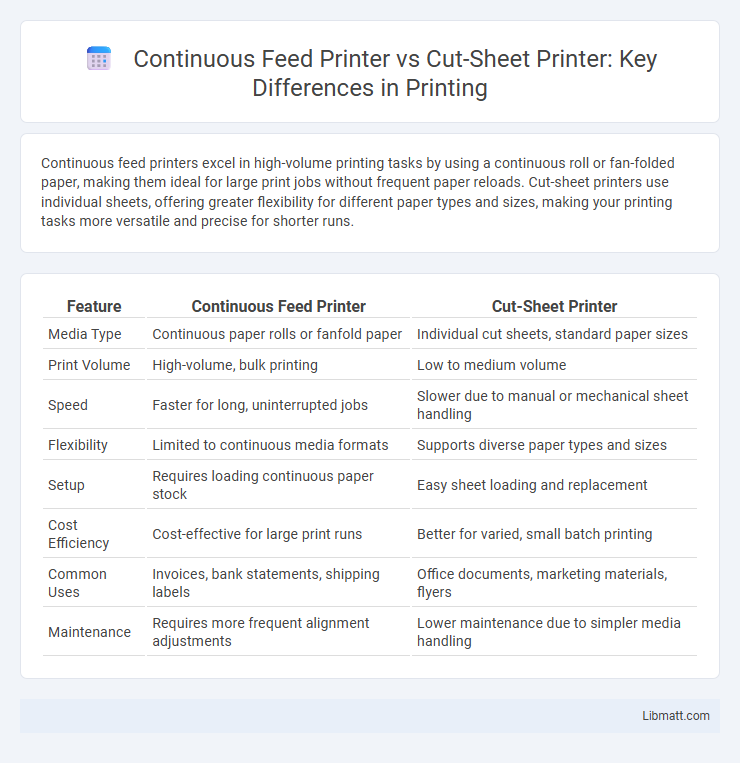

Continuous feed printers excel in high-volume printing tasks by using a continuous roll or fan-folded paper, making them ideal for large print jobs without frequent paper reloads. Cut-sheet printers use individual sheets, offering greater flexibility for different paper types and sizes, making your printing tasks more versatile and precise for shorter runs.

Table of Comparison

| Feature | Continuous Feed Printer | Cut-Sheet Printer |

|---|---|---|

| Media Type | Continuous paper rolls or fanfold paper | Individual cut sheets, standard paper sizes |

| Print Volume | High-volume, bulk printing | Low to medium volume |

| Speed | Faster for long, uninterrupted jobs | Slower due to manual or mechanical sheet handling |

| Flexibility | Limited to continuous media formats | Supports diverse paper types and sizes |

| Setup | Requires loading continuous paper stock | Easy sheet loading and replacement |

| Cost Efficiency | Cost-effective for large print runs | Better for varied, small batch printing |

| Common Uses | Invoices, bank statements, shipping labels | Office documents, marketing materials, flyers |

| Maintenance | Requires more frequent alignment adjustments | Lower maintenance due to simpler media handling |

Introduction to Continuous Feed and Cut-Sheet Printers

Continuous feed printers use long rolls or fan-folded stacks of paper that are fed through the printer automatically, enabling high-volume printing with minimal interruptions. Cut-sheet printers accept individual sheets of paper manually or via automatic feeders, offering greater flexibility for varied print sizes and types. Continuous feed models excel in large-scale, uninterrupted production environments, while cut-sheet printers are preferred for diverse, on-demand printing tasks.

How Continuous Feed Printers Work

Continuous feed printers use a long roll or stack of connected paper with perforations between sheets, allowing for uninterrupted printing of large documents or forms. This mechanism reduces paper jams and increases efficiency, making it ideal for high-volume jobs like invoices or shipping labels. Your printing process benefits from faster throughput and less manual handling compared to cut-sheet printers that handle individual sheets one at a time.

How Cut-Sheet Printers Operate

Cut-sheet printers operate by feeding individual sheets of paper through the printing mechanism one at a time, allowing precise control over paper handling and print quality. These printers use either laser or inkjet technology to apply toner or ink onto each sheet, enabling high-resolution output suitable for diverse media types and sizes. The ability to switch between different paper stocks quickly makes cut-sheet printers ideal for variable data printing and short-run jobs.

Key Differences Between Continuous Feed and Cut-Sheet Printers

Continuous feed printers use large rolls of paper, allowing for high-volume, uninterrupted printing ideal for printing lengthy documents or labels. Cut-sheet printers handle individual sheets, offering greater flexibility and precision for varied print jobs, such as brochures or flyers. Your choice depends on the required print volume, speed, and paper handling preferences.

Print Speed and Volume Comparison

Continuous feed printers excel in high-volume printing environments due to their ability to produce thousands of pages per hour without frequent paper reloads, making them ideal for large-scale tasks like invoices and statements. Cut-sheet printers operate at slower speeds, typically around 20-100 pages per minute, and require manual or automatic reloading after each batch, limiting efficiency in bulk printing. For enterprises prioritizing rapid output and uninterrupted printing, continuous feed systems significantly outperform cut-sheet printers in both speed and volume capabilities.

Print Quality and Media Flexibility

Continuous feed printers deliver superior print quality with consistent color density and sharp text, ideal for high-volume printing on continuous paper rolls. Cut-sheet printers offer greater media flexibility, capable of handling various paper sizes, weights, and types, including cardstock and specialty media. Your choice depends on whether you prioritize high-quality, continuous output or versatile media options for diverse printing needs.

Cost Efficiency and Operational Expenses

Continuous feed printers generally offer lower operational expenses due to bulk paper usage and reduced downtime from fewer reloads, making them cost-efficient for high-volume printing tasks. Cut-sheet printers, while typically requiring higher per-sheet costs and more frequent paper replacement, provide greater flexibility for variable print jobs and smaller runs. Businesses should evaluate volume demands and print job variability to determine which printer type maximizes cost efficiency and aligns with their operational budget.

Typical Applications for Each Printer Type

Continuous feed printers excel in high-volume printing tasks such as invoices, shipping labels, and bulk mailing, where large quantities of uniform documents are required efficiently. Cut-sheet printers are ideal for diverse print jobs like brochures, flyers, and personalized marketing materials, providing greater flexibility with various paper sizes and types. Your choice depends on whether you need speed and volume or versatility and customization in your printing workflow.

Advantages and Disadvantages of Continuous Feed Printers

Continuous feed printers excel in high-volume printing with minimal interruptions due to their ability to handle large stacks of paper on a roll, significantly improving efficiency in mass print jobs like invoices and labels. Their disadvantages include limited paper size flexibility and higher initial setup costs compared to cut-sheet printers, which use individual sheets, offering more versatility for varied printing tasks. Continuous feed printers also tend to consume more power and require more maintenance, impacting overall operational costs.

Choosing the Right Printer: Factors to Consider

Continuous feed printers excel in high-volume, uninterrupted printing tasks with precise alignment on fanfold paper, making them ideal for bulk invoices and forms. Cut-sheet printers offer greater versatility and faster setup for varied print jobs, supporting multiple paper sizes and types suited for office documents and marketing materials. Consider print speed, volume, media flexibility, and maintenance costs when selecting the best option for your business needs.

continuous feed printer vs cut-sheet printer Infographic

libmatt.com

libmatt.com