Overprint varnish applies selectively on printed areas to enhance gloss and protection without affecting colors, while flood varnish coats the entire surface uniformly for maximum coverage and a consistent finish. Your choice depends on whether you want targeted embellishment or full-surface durability and sheen.

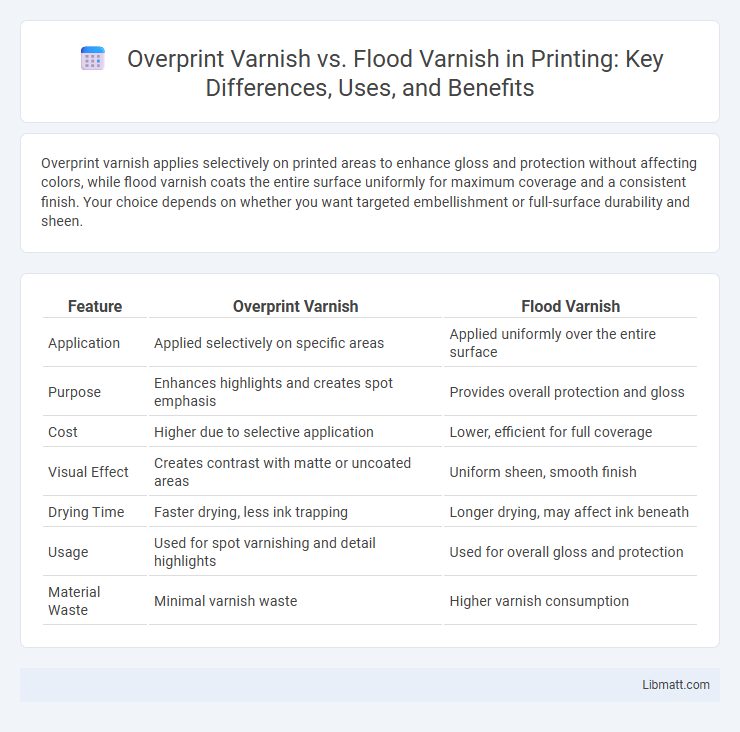

Table of Comparison

| Feature | Overprint Varnish | Flood Varnish |

|---|---|---|

| Application | Applied selectively on specific areas | Applied uniformly over the entire surface |

| Purpose | Enhances highlights and creates spot emphasis | Provides overall protection and gloss |

| Cost | Higher due to selective application | Lower, efficient for full coverage |

| Visual Effect | Creates contrast with matte or uncoated areas | Uniform sheen, smooth finish |

| Drying Time | Faster drying, less ink trapping | Longer drying, may affect ink beneath |

| Usage | Used for spot varnishing and detail highlights | Used for overall gloss and protection |

| Material Waste | Minimal varnish waste | Higher varnish consumption |

Understanding Overprint Varnish: Definition and Applications

Overprint varnish is a clear coating applied selectively over printed areas to enhance durability and gloss without covering the entire surface, making it ideal for highlighting specific design elements. It offers protection against scratches and smudges while preserving the underlying print quality, often used in packaging and high-end marketing materials. Your choice between overprint varnish and flood varnish depends on whether you want targeted enhancement or full-surface protection.

What Is Flood Varnish? Key Characteristics

Flood varnish is a protective coating applied uniformly across an entire printed surface, enhancing durability and visual appeal with a smooth, glossy or matte finish. It offers comprehensive coverage that safeguards printed materials against scratches, moisture, and UV damage while improving color vibrancy and contrast. Flood varnish is ideal for large print runs, creating a consistent layer that strengthens paper stock without disrupting text or graphic elements.

Overprint Varnish vs Flood Varnish: Core Differences

Overprint varnish is applied selectively on specific areas of a printed substrate, enhancing contrast, texture, and spot gloss effects, whereas flood varnish covers the entire surface for overall protection and uniform finish. Overprint varnish is typically used to highlight design elements without altering the underlying print, while flood varnish creates a consistent layer that safeguards against abrasion, moisture, and UV damage. The choice between overprint and flood varnish depends on the desired visual impact, cost considerations, and functional requirements of the printed material.

Visual Impact: Gloss, Matte, and Texture Variations

Overprint varnish enhances visual impact by selectively adding gloss or matte finishes to specific design elements, creating depth and contrast without altering the overall texture of the print. Flood varnish covers the entire surface uniformly, providing consistent gloss or matte effects that enhance the print's richness but lack localized texture variations. Choosing between the two depends on whether the design demands subtle highlights with tactile differences or a uniform finish for a polished appearance.

Protection and Durability: Which Varnish Lasts Longer?

Overprint varnish offers superior protection by applying a thin, precise layer only to specific areas, enhancing durability where it's needed most without compromising other parts of the print. Flood varnish, covering the entire surface, provides uniform protection but may be more prone to wear and scuffing over time due to its broader application. Your choice between overprint and flood varnish should consider whether targeted longevity or overall coverage better suits your project's durability requirements.

Printing Techniques: Application Processes Compared

Overprint varnish is selectively applied over specific printed areas using precise plate or digital printing methods, enhancing protection and gloss without affecting underlying colors. Flood varnish covers the entire surface uniformly, typically applied via roller or spray methods, providing consistent sheen and protection across the print. The choice between these application processes impacts drying times, ink compatibility, and the final visual texture in production workflows.

Cost Efficiency: Budget Considerations for Each Option

Overprint varnish offers cost efficiency by applying varnish only to specific areas, reducing material usage and cutting down on drying time, which benefits budgets focused on precision and smaller runs. Flood varnish covers the entire surface, increasing varnish consumption and drying time, potentially raising costs but providing uniform protection and a glossy finish ideal for larger print jobs. Choosing between overprint and flood varnish depends on the project scale and budget constraints, balancing targeted finish quality against overall coverage expense.

Suitability for Different Printing Projects

Overprint varnish offers precise application, making it ideal for projects requiring selective highlighting on specific design elements or text, enhancing visual contrast without affecting the entire surface. Flood varnish covers the entire printed area uniformly, providing a consistent protective layer suitable for mass-produced materials like brochures or postcards where overall durability and sheen are desired. Choosing between overprint and flood varnish depends on the desired visual effect and the level of protection required for the printing substrate.

Environmental Impact: Sustainability and Eco-Friendliness

Overprint varnish uses less material and generates less waste compared to flood varnish, contributing to lower environmental impact through reduced chemical usage and energy consumption. Flood varnish covers the entire printed sheet, often resulting in higher volatile organic compound (VOC) emissions, making it less eco-friendly. Choosing overprint varnish supports sustainability goals by minimizing resource use and enhancing recyclability of printed materials.

Choosing the Right Varnish for Your Print Needs

Selecting the right varnish depends on the desired finish and print protection; overprint varnish offers precise, targeted application over specific areas, enhancing highlights and images without affecting the entire print, while flood varnish covers the whole surface uniformly for a consistent glossy or matte look. Overprint varnish is ideal for spot treatments and enhancing visual appeal on detailed elements, whereas flood varnish provides broad protection against wear and tear. Consider the print material, design complexity, and finishing requirements to determine the most suitable varnish type for optimal durability and aesthetic impact.

overprint varnish vs flood varnish Infographic

libmatt.com

libmatt.com