Single-pass printing offers faster production by using a fixed print head that covers the entire media width in one pass, ideal for high-volume jobs requiring efficiency. Multi-pass printing enhances image quality and color accuracy by applying multiple layers of ink, making it suitable for detailed graphics and smaller runs where precision is key.

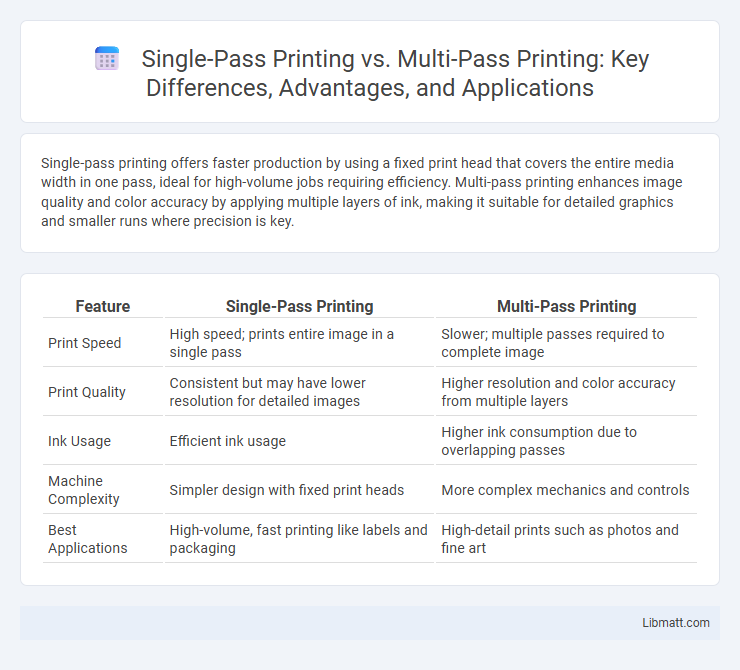

Table of Comparison

| Feature | Single-Pass Printing | Multi-Pass Printing |

|---|---|---|

| Print Speed | High speed; prints entire image in a single pass | Slower; multiple passes required to complete image |

| Print Quality | Consistent but may have lower resolution for detailed images | Higher resolution and color accuracy from multiple layers |

| Ink Usage | Efficient ink usage | Higher ink consumption due to overlapping passes |

| Machine Complexity | Simpler design with fixed print heads | More complex mechanics and controls |

| Best Applications | High-volume, fast printing like labels and packaging | High-detail prints such as photos and fine art |

Introduction to Printing Technologies

Single-pass printing utilizes a fixed array of printheads that apply ink to the substrate in one swift motion, enabling high-speed production ideal for large-scale industrial applications. Multi-pass printing involves multiple passes of a moving printhead over the same area, allowing for higher resolution and finer detail, commonly used in graphic and photo printing. These distinct approaches influence print quality, speed, and cost-efficiency depending on the specific technology and user requirements.

What is Single-Pass Printing?

Single-pass printing is a high-speed digital printing technique where the printheads remain stationary as a substrate moves beneath them, allowing the entire image to be printed in a single pass. This method uses multiple printheads aligned across the printing width to deposit ink simultaneously, resulting in faster production and consistent image quality. Ideal for large-volume runs, single-pass printing reduces processing time and minimizes the risk of misalignment compared to multi-pass printing methods.

What is Multi-Pass Printing?

Multi-pass printing involves the print head making several passes over the same area to build up ink layers, enhancing print quality and color accuracy. This method reduces imperfections such as banding and allows for finer details, making it ideal for high-resolution images and professional-grade prints. When you require exceptional print clarity and depth, multi-pass printing delivers superior results compared to single-pass techniques.

Key Differences: Single-Pass vs Multi-Pass

Single-pass printing uses a fixed array of printheads that cover the entire width of the media, delivering faster production speeds and consistent print quality in a single pass. Multi-pass printing moves the printhead across the media multiple times, allowing for higher resolution and better image quality but at the cost of slower throughput. Key differences include speed, print quality, and mechanical complexity, with single-pass favored for high-volume runs and multi-pass suited for detailed, small-batch jobs.

Print Speed Comparison

Single-pass printing offers significantly faster print speeds by using fixed print heads that cover the entire width of the substrate, allowing your device to print in one continuous pass. In contrast, multi-pass printing moves the print heads back and forth across the substrate multiple times to build the image, resulting in slower output. For projects requiring high-speed production, single-pass printers deliver superior efficiency without compromising quality.

Image Quality and Consistency

Single-pass printing delivers superior image quality and consistency by printing the entire image in one rapid pass, minimizing registration errors and ensuring uniform ink application. Multi-pass printing can produce high-quality images but may suffer from slight misalignments and color variations due to multiple passes over the same area. Your choice between these methods impacts the precision and reliability of the final printed output.

Cost Efficiency and Productivity

Single-pass printing offers superior cost efficiency by using fewer printheads and reducing operational time, making it ideal for high-volume production environments. Multi-pass printing provides higher print quality and greater detail but requires multiple passes that increase ink consumption and slow down productivity. For your business, selecting single-pass printing can maximize throughput and reduce long-term expenses without compromising essential output quality.

Ideal Applications for Single-Pass Printing

Single-pass printing excels in high-speed production environments such as packaging, label printing, and industrial printing where rapid output and consistent quality are essential. Your operations benefit from minimal downtime and efficient use of resources due to the simultaneous application of all ink colors in one pass. This method is ideal for large-scale runs requiring fast turnaround without compromising print resolution or detail.

Best Use Cases for Multi-Pass Printing

Multi-pass printing is ideal for applications requiring superior image quality and color accuracy, such as high-resolution photo prints, fine art reproductions, and detailed graphics. By passing the print head over the same area multiple times, it reduces banding and enhances color depth, making it suitable for professional photography and graphic design projects. Your prints benefit from this precision when color fidelity and smooth gradients are critical to the final output.

Choosing the Right Printing Method for Your Needs

Single-pass printing offers faster production by printing the entire page in one pass, making it ideal for high-volume jobs requiring efficiency. Multi-pass printing delivers higher print quality and detail by printing multiple layers, suitable for intricate designs or materials needing precise color accuracy. Your choice depends on balancing speed, quality, and budget to match the specific requirements of your printing project.

Single-Pass vs Multi-Pass Printing Infographic

libmatt.com

libmatt.com