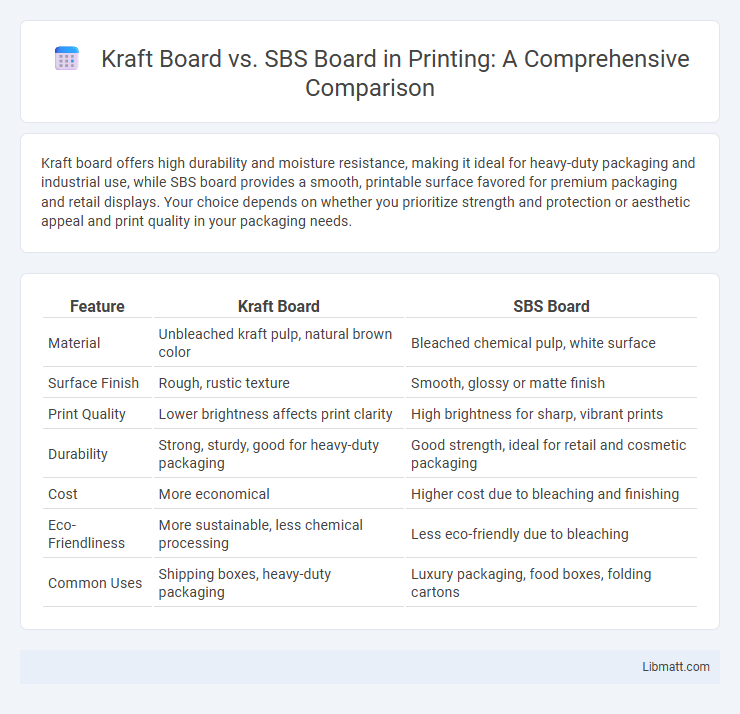

Kraft board offers high durability and moisture resistance, making it ideal for heavy-duty packaging and industrial use, while SBS board provides a smooth, printable surface favored for premium packaging and retail displays. Your choice depends on whether you prioritize strength and protection or aesthetic appeal and print quality in your packaging needs.

Table of Comparison

| Feature | Kraft Board | SBS Board |

|---|---|---|

| Material | Unbleached kraft pulp, natural brown color | Bleached chemical pulp, white surface |

| Surface Finish | Rough, rustic texture | Smooth, glossy or matte finish |

| Print Quality | Lower brightness affects print clarity | High brightness for sharp, vibrant prints |

| Durability | Strong, sturdy, good for heavy-duty packaging | Good strength, ideal for retail and cosmetic packaging |

| Cost | More economical | Higher cost due to bleaching and finishing |

| Eco-Friendliness | More sustainable, less chemical processing | Less eco-friendly due to bleaching |

| Common Uses | Shipping boxes, heavy-duty packaging | Luxury packaging, food boxes, folding cartons |

Understanding Kraft Board: Key Features

Kraft board is a sturdy, eco-friendly material made from recycled kraft paper that offers excellent durability and tear resistance, making it ideal for packaging and shipping. It features a natural brown color, high tensile strength, and moisture resistance due to the long fibers in kraft pulp. Commonly used in envelopes, corrugated boxes, and paper bags, kraft board provides sustainability benefits linked to its biodegradable and recyclable properties.

What is SBS Board? An Overview

SBS board, or Solid Bleached Sulfate board, is a high-quality paperboard made from bleached chemical pulp, renowned for its smooth surface and purity. It offers excellent printability, strength, and moisture resistance, making it ideal for premium packaging such as cosmetics, pharmaceuticals, and food products. Unlike Kraft board, which is more fibrous and unbleached, SBS board provides a clean, white appearance and superior aesthetic appeal.

Composition and Manufacturing Differences

Kraft Board is made primarily from virgin kraft pulp, offering high strength and durability through a natural, unbleached fiber composition, commonly produced by a kraft process that includes chemical pulping and bleaching stages. SBS (Solid Bleached Sulfate) Board consists of fully bleached virgin wood fibers, providing a smooth, white surface ideal for high-quality packaging, and is manufactured through a sulfite chemical pulping process followed by extensive bleaching. The manufacturing differences result in Kraft Board being more rugged with a natural brown color, while SBS Board delivers a pristine, bright-white finish suitable for premium printing and folding applications.

Strength and Durability Comparison

Kraft board offers high tensile strength and excellent tear resistance due to its unbleached wood fibers, making it ideal for heavy-duty packaging and industrial applications. SBS (Solid Bleached Sulfate) board features superior surface strength and smoothness, providing excellent durability against moisture and grease, which is preferred for premium retail packaging and cosmetic boxes. While Kraft board excels in structural support and environmental sustainability, SBS board provides better printability and aesthetics with strong resistance to bending and crushing.

Printability and Surface Quality

Kraft Board offers excellent durability but has a rougher surface, making it less ideal for high-quality printing compared to SBS Board. SBS Board provides superior printability due to its smooth, white, and uniform surface that enhances color vibrancy and detail accuracy. The surface quality of SBS Board supports advanced printing techniques such as UV coating and foil stamping, which are challenging to achieve on Kraft Board.

Applications of Kraft Board

Kraft Board is widely used in packaging due to its high strength, durability, and resistance to tearing, making it ideal for shipping boxes, industrial packaging, and heavy-duty cartons. Its eco-friendly properties and recyclability make it a preferred choice for sustainable product packaging in industries like food, cosmetics, and electronics. Compared to SBS Board, Kraft Board excels in applications requiring robust protection and structural integrity, especially in environments demanding moisture resistance and durability.

Common Uses for SBS Board

SBS Board, known for its smooth surface and excellent printability, is commonly used in luxury packaging, retail boxes, and food containers where high-quality graphics and protection are essential. It is often preferred for cosmetics, confectionery, and pharmaceutical packaging due to its sturdy structure and ability to provide a premium feel. The board's resistance to moisture and grease makes it suitable for frozen food packaging and other applications requiring hygienic and durable material.

Environmental Impact: Kraft vs SBS

Kraft board is highly regarded for its eco-friendly qualities, made from unbleached wood pulp that reduces chemical use and fosters biodegradability, contributing to a lower environmental footprint compared to SBS (Solid Bleached Sulfate) board. SBS board undergoes a bleaching process using chlorinated compounds, which can result in higher energy consumption and increased chemical residues, impacting water systems and sustainability efforts. Choosing Kraft board supports recycling initiatives and sustainable forestry practices, making it a preferable option for environmentally conscious packaging and paper products.

Cost Considerations and Availability

Kraft Board typically offers a more cost-effective solution compared to SBS Board due to its lower production expenses and widespread availability, making it ideal for budget-sensitive projects. SBS Board, known for its superior print quality and smooth surface, generally incurs higher costs and may have limited stock in certain regions, affecting lead times and pricing. Understanding Your project's requirements and local market supply can help balance cost and quality when choosing between Kraft and SBS boards.

Choosing the Right Board for Your Packaging Needs

Kraft board offers excellent strength and eco-friendliness, making it ideal for sustainable packaging requiring durability and moisture resistance. SBS board delivers superior print quality and a smooth surface, perfect for high-end retail packaging where visual appeal is crucial. Understanding your packaging priorities, whether durability or aesthetics, helps you select the right board for your product's protection and presentation needs.

Kraft Board vs SBS Board Infographic

libmatt.com

libmatt.com