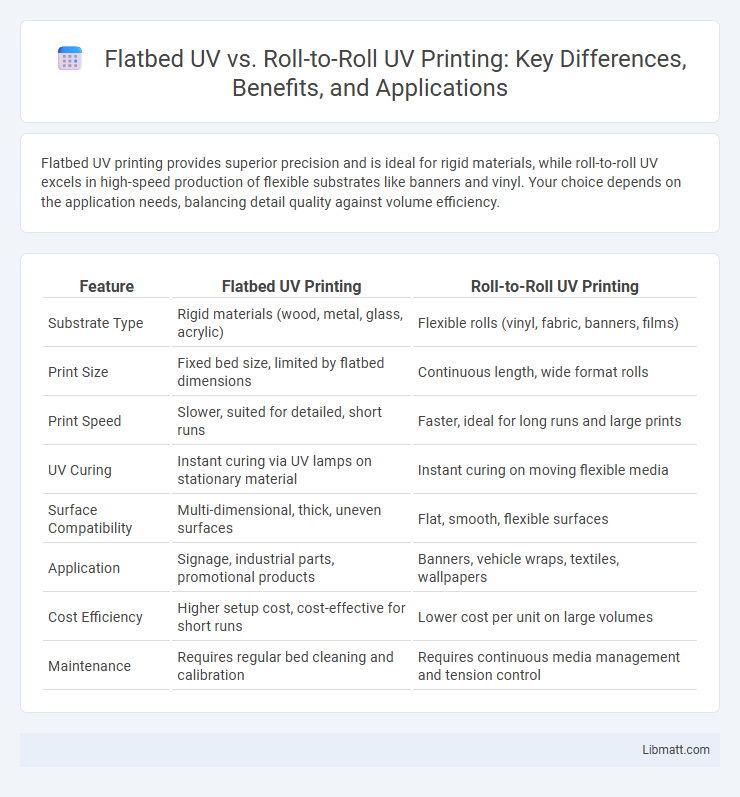

Flatbed UV printing provides superior precision and is ideal for rigid materials, while roll-to-roll UV excels in high-speed production of flexible substrates like banners and vinyl. Your choice depends on the application needs, balancing detail quality against volume efficiency.

Table of Comparison

| Feature | Flatbed UV Printing | Roll-to-Roll UV Printing |

|---|---|---|

| Substrate Type | Rigid materials (wood, metal, glass, acrylic) | Flexible rolls (vinyl, fabric, banners, films) |

| Print Size | Fixed bed size, limited by flatbed dimensions | Continuous length, wide format rolls |

| Print Speed | Slower, suited for detailed, short runs | Faster, ideal for long runs and large prints |

| UV Curing | Instant curing via UV lamps on stationary material | Instant curing on moving flexible media |

| Surface Compatibility | Multi-dimensional, thick, uneven surfaces | Flat, smooth, flexible surfaces |

| Application | Signage, industrial parts, promotional products | Banners, vehicle wraps, textiles, wallpapers |

| Cost Efficiency | Higher setup cost, cost-effective for short runs | Lower cost per unit on large volumes |

| Maintenance | Requires regular bed cleaning and calibration | Requires continuous media management and tension control |

Introduction to UV Printing Technologies

Flatbed UV printing uses a rigid, stationary platform allowing direct printing on thick and rigid materials with high precision and detailed image quality. Roll-to-roll UV printing processes flexible substrates continuously, ideal for large-volume, high-speed production of banners, decals, and textiles. Both technologies employ ultraviolet light to instantly cure inks, enhancing durability and vibrancy on diverse surfaces.

What is Flatbed UV Printing?

Flatbed UV printing uses a stationary, flat surface to print directly onto rigid or thick materials such as wood, glass, or metal with ultraviolet-curable inks. This method allows precise, high-resolution images on substrates that cannot be fed through rollers, enabling customization for signage, packaging, and industrial applications. The UV light instantly cures the ink, ensuring vibrant colors and durable finishes on diverse flat materials.

What is Roll-to-Roll UV Printing?

Roll-to-roll UV printing is a digital printing technology where flexible materials like vinyl or fabric are continuously fed through a printer using rollers, allowing for high-speed production of large graphics. Unlike flatbed UV printing, which prints on rigid substrates by placing them on a stationary flat surface, roll-to-roll UV excels in producing banners, decals, and vehicle wraps with vibrant, durable UV-cured inks. Your choice depends on the substrate type and project scale, with roll-to-roll UV ideal for flexible media and extended print runs.

Key Differences Between Flatbed and Roll-to-Roll UV Printers

Flatbed UV printers use a stationary flat surface to print directly onto rigid materials, offering high precision and versatility for substrates like wood, glass, and metal, while roll-to-roll UV printers handle flexible media on rolls, ideal for large-scale banner and fabric printing. The key differences include media compatibility, with flatbed printers excelling in thickness and rigidity, whereas roll-to-roll systems provide continuous printing for longer runs and faster throughput. Your choice depends on the application requirements, balancing the need for detailed graphics on solid substrates or high-volume printing on flexible materials.

Material Compatibility: Flatbed vs Roll-to-Roll

Flatbed UV printers excel in handling rigid and thick materials such as wood, glass, metal, and acrylic, providing high-quality prints with precise detail. Roll-to-roll UV printers are optimized for flexible materials like vinyl, fabric, and banners, allowing continuous printing on large rolls for extended production runs. Your choice between flatbed and roll-to-roll UV printing should consider the specific material compatibility needed for your project to achieve optimal results.

Print Quality and Versatility Comparison

Flatbed UV printers deliver superior print quality with precise detail and vibrant colors on rigid and thick substrates, offering unmatched versatility for diverse materials such as wood, glass, and metal. Roll-to-roll UV printers excel in high-speed production and continuous printing on flexible materials like vinyl and fabric, but may sacrifice some detail sharpness compared to flatbed systems. Your choice depends on whether high-quality static prints or large-volume flexible media production is the priority.

Speed and Production Efficiency Analysis

Flatbed UV printers offer precise, high-quality printing with slower speeds, making them ideal for rigid substrates and detailed designs. Roll-to-roll UV printers excel in speed and production efficiency by continuously feeding flexible materials, perfect for large-volume print jobs like banners and textiles. Your choice depends on balancing the need for production speed and the type of material you intend to print on.

Cost Considerations: Investment and Operation

Flatbed UV printers typically require a higher initial investment due to their advanced hardware and larger build size, making them suitable for businesses with varied and rigid media needs. Roll-to-roll UV printers tend to have a lower upfront cost and are more cost-effective for continuous, high-volume production on flexible substrates. Your choice should weigh both the capital expenditure and ongoing operational costs, including maintenance, material usage, and workflow efficiency.

Ideal Applications for Flatbed and Roll-to-Roll UV Printers

Flatbed UV printers excel in printing on rigid, thick, or irregularly shaped materials such as wood, glass, metal, and acrylic, making them ideal for signage, promotional items, and industrial applications requiring high precision. Roll-to-roll UV printers are best suited for flexible media like vinyl, fabric, and banners, providing continuous printing for large-format applications including billboards, vehicle wraps, and textile graphics. Your choice depends on the substrate type and production volume, with flatbed offering versatility for diverse materials and roll-to-roll enabling efficient handling of long, flexible media.

Choosing the Right UV Printing Solution for Your Business

Flatbed UV printers excel in producing high-quality prints on rigid materials, making them ideal for businesses specializing in custom signage, packaging, and promotional items. Roll-to-roll UV printers offer superior efficiency for large-volume printing on flexible substrates like vinyl banners and textiles, providing cost-effective scalability. Selecting the right UV printing solution depends on your production volume, substrate type, and desired print durability to maximize return on investment and operational efficiency.

Flatbed UV vs roll-to-roll UV Infographic

libmatt.com

libmatt.com