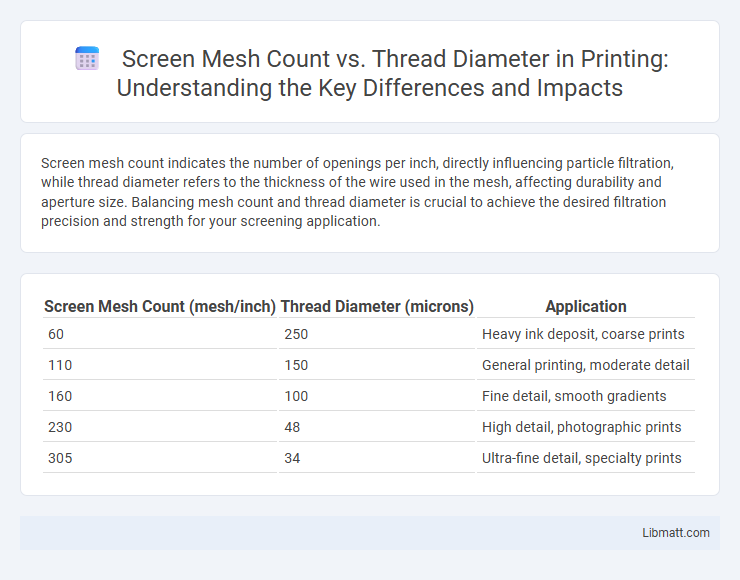

Screen mesh count indicates the number of openings per inch, directly influencing particle filtration, while thread diameter refers to the thickness of the wire used in the mesh, affecting durability and aperture size. Balancing mesh count and thread diameter is crucial to achieve the desired filtration precision and strength for your screening application.

Table of Comparison

| Screen Mesh Count (mesh/inch) | Thread Diameter (microns) | Application |

|---|---|---|

| 60 | 250 | Heavy ink deposit, coarse prints |

| 110 | 150 | General printing, moderate detail |

| 160 | 100 | Fine detail, smooth gradients |

| 230 | 48 | High detail, photographic prints |

| 305 | 34 | Ultra-fine detail, specialty prints |

Introduction to Screen Mesh Count and Thread Diameter

Screen mesh count refers to the number of threads per inch in a screen, directly affecting the mesh's ability to filter particles. Thread diameter denotes the thickness of each thread, influencing the screen's strength and openness. Your choice between mesh count and thread diameter impacts the balance of filtration precision and durability in applications like sieving or filtration.

Understanding Screen Mesh Count

Screen mesh count refers to the number of threads per inch in a screen, directly affecting the filtration precision and particle retention. Higher mesh counts indicate finer mesh with smaller thread diameters, allowing for better separation of tiny particles, while lower mesh counts have thicker threads and larger openings. Understanding screen mesh count helps you select the right mesh size for your specific screening requirements, balancing flow rate and filtration accuracy.

What is Thread Diameter in Screen Printing?

Thread diameter in screen printing refers to the thickness of each individual thread woven into the mesh fabric, directly influencing the mesh's openness and ink flow. A smaller thread diameter allows for a higher mesh count and finer detail in your prints, while a larger diameter creates more durability and greater ink deposit. Understanding thread diameter helps optimize print quality by balancing detail resolution with ink saturation on your screen printing projects.

How Mesh Count Influences Print Quality

Mesh count directly impacts print quality by determining the amount of detail and ink deposit during screen printing. Higher mesh counts, with finer thread diameters, allow for sharper images and smoother gradients but require thinner ink layers, which are ideal for intricate designs. Your choice of mesh count must balance between achieving fine detail and the necessary ink thickness to ensure durability and color vibrancy.

The Role of Thread Diameter in Ink Flow

Thread diameter plays a crucial role in ink flow through screen mesh by determining the size of open spaces for ink passage. Larger thread diameters reduce mesh openings, restricting ink flow and increasing ink deposit thickness on the substrate. Understanding the balance between thread diameter and mesh count helps you achieve precise ink application and optimal print quality.

Mesh Count vs Thread Diameter: Key Differences

Mesh count refers to the number of threads per inch in a screen, directly impacting the screen's fineness and filtration capability. Thread diameter measures the thickness of each individual thread, influencing the screen's strength and durability. Understanding the key differences between mesh count and thread diameter helps you select the right screen mesh for optimal performance in filtering or screening applications.

Choosing the Right Mesh Count and Thread Diameter

Selecting the appropriate screen mesh count and thread diameter is crucial for effective filtration and screening applications, as mesh count determines the number of openings per inch while thread diameter influences the strength and durability of the screen. A higher mesh count offers finer filtration but requires thinner threads, which may reduce screen strength, whereas a lower mesh count with thicker thread diameter provides increased durability but less precision. Balancing mesh count and thread diameter based on material particle size and application requirements ensures optimal performance and longevity of the screen.

Effects on Detail, Opacity, and Durability

Higher screen mesh counts with finer thread diameters enhance detail by allowing more precise ink deposits and sharper images in screen printing. Your designs gain increased opacity as the denser mesh reduces ink bleed-through, resulting in more vibrant prints. However, finer threads may lower durability, requiring careful handling to maintain screen integrity during repeated use.

Common Mesh Count and Thread Diameter Combinations

Common mesh count and thread diameter combinations in screen mesh significantly influence filtration efficiency and material strength. For example, a 100 mesh screen typically features a thread diameter of approximately 0.0047 inches, balancing fine particle filtration with durability. The correlation between mesh count and thread diameter ensures optimal open area, affecting airflow, visibility, and material retention in applications like sieving, insect screening, and industrial filtration.

Tips for Selecting the Best Screen for Your Project

Choosing the best screen mesh for your project requires balancing mesh count and thread diameter to achieve optimal filtration or separation efficiency. A higher mesh count with thinner thread diameters offers finer filtration but reduces strength and durability, while lower mesh counts with thicker threads provide greater strength and airflow at the expense of filtering precision. Evaluating the material type, environmental conditions, and desired particle size will guide selecting a screen mesh with the right combination of thread diameter and mesh count for your specific application.

Screen mesh count vs thread diameter Infographic

libmatt.com

libmatt.com