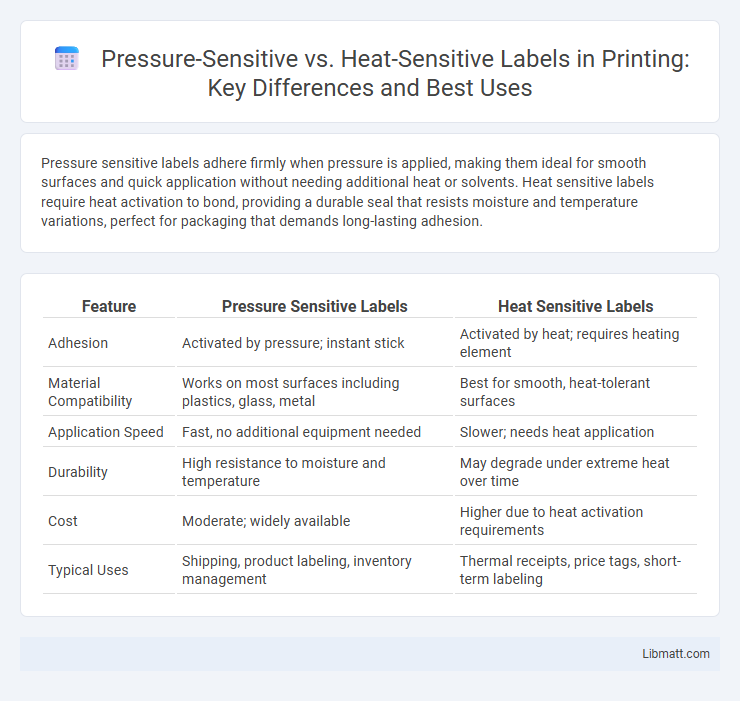

Pressure sensitive labels adhere firmly when pressure is applied, making them ideal for smooth surfaces and quick application without needing additional heat or solvents. Heat sensitive labels require heat activation to bond, providing a durable seal that resists moisture and temperature variations, perfect for packaging that demands long-lasting adhesion.

Table of Comparison

| Feature | Pressure Sensitive Labels | Heat Sensitive Labels |

|---|---|---|

| Adhesion | Activated by pressure; instant stick | Activated by heat; requires heating element |

| Material Compatibility | Works on most surfaces including plastics, glass, metal | Best for smooth, heat-tolerant surfaces |

| Application Speed | Fast, no additional equipment needed | Slower; needs heat application |

| Durability | High resistance to moisture and temperature | May degrade under extreme heat over time |

| Cost | Moderate; widely available | Higher due to heat activation requirements |

| Typical Uses | Shipping, product labeling, inventory management | Thermal receipts, price tags, short-term labeling |

Introduction to Label Technologies

Pressure sensitive labels use adhesive that bonds when pressure is applied, making them ideal for quick and easy application on various surfaces without heat. Heat sensitive labels, also known as thermal labels, require thermal transfer or direct thermal printing technology to create images through heat activation on special coated paper. Understanding these label technologies helps you choose the most efficient and durable labeling solution based on your packaging needs and environmental conditions.

What Are Pressure Sensitive Labels?

Pressure sensitive labels consist of a flexible face material coated with a pressure-activated adhesive, allowing them to stick securely to various surfaces without the need for heat or water. These labels offer quick application and strong bonding on materials like glass, plastic, and metal, making them ideal for retail, packaging, and product identification. Their versatility includes options such as permanent, removable, and repositionable adhesives to suit different use cases and environmental conditions.

What Are Heat Sensitive Labels?

Heat sensitive labels are designed to change color or reveal hidden information when exposed to specific temperatures, utilizing thermochromic or heat-activated inks. These labels are often used in applications requiring temperature monitoring, such as packaging for perishable goods or safety warnings. Your choice of heat sensitive labels can enhance product safety and provide real-time temperature indicators without the need for additional equipment.

Key Differences Between Pressure and Heat Sensitive Labels

Pressure sensitive labels adhere to surfaces through a pressure-activated adhesive that requires no heat or water, making them ideal for quick and versatile applications on various materials. Heat sensitive labels rely on heat to activate their adhesive or color-changing properties, commonly used in thermal transfer printing and temperature monitoring in packaging. The key differences between pressure and heat sensitive labels lie in their application methods, adhesive activation, and suitability for different environmental conditions and surfaces.

Application Processes: Pressure vs Heat Sensitivity

Pressure sensitive labels adhere to surfaces through the application of pressure, activating a pre-applied adhesive that bonds instantly without requiring additional heat or water. Heat sensitive labels, often found in thermal printing, react to heat to create images or text, either via direct thermal or thermal transfer processes, necessitating controlled temperature settings for proper application. Selecting between the two depends on the specific application environment, substrate compatibility, and durability requirements for the labeling process.

Material Compatibility and Substrate Options

Pressure sensitive labels offer exceptional versatility, adhering effectively to a wide range of materials including plastics, glass, metals, and paper, making them ideal for various substrate options without additional treatment. Heat sensitive labels, also known as thermal labels, require specific thermal paper or synthetic substrates designed to react to heat, limiting compatibility primarily to smooth surfaces such as coated papers and certain synthetics. Understanding your material compatibility ensures optimal adhesion and print quality, enhancing the durability and functionality of your labeling solution.

Cost Considerations for Each Label Type

Pressure sensitive labels generally offer lower upfront costs due to simpler application processes and compatibility with various surfaces, making them cost-effective for short to medium production runs. Heat sensitive labels, while typically more expensive initially due to specialized materials and equipment requirements, provide durable performance ideal for high-temperature environments, potentially reducing long-term replacement costs. Evaluating application volume, environmental conditions, and durability needs is crucial when comparing total cost efficiency between pressure sensitive and heat sensitive labels.

Durability and Environmental Resistance

Pressure sensitive labels offer superior durability and environmental resistance, making them ideal for applications exposed to moisture, chemicals, and varying temperatures. Heat sensitive labels, also known as thermal labels, are less durable and tend to degrade when exposed to prolonged heat, moisture, or UV light. While pressure sensitive labels maintain adhesion and legibility in harsh conditions, heat sensitive labels are better suited for short-term use in controlled environments.

Industry Use Cases and Common Applications

Pressure sensitive labels dominate industries requiring quick, reliable adhesion to diverse surfaces such as pharmaceuticals, food and beverage packaging, and cosmetics, due to their strong bond and ease of application without heat. Heat sensitive labels are prevalent in thermal printing applications like shipping labels, receipts, and barcode tags within retail and logistics sectors, offering durability and smudge resistance under varying temperature conditions. Both label types optimize operational efficiency across manufacturing, warehousing, and retail by catering to specific adhesive and environmental demands inherent to different industry use cases.

Choosing the Right Label for Your Needs

Pressure sensitive labels adhere through pressure activation, making them ideal for smooth or irregular surfaces without the need for heat, while heat sensitive labels require heat to activate the adhesive, providing strong bonds suited for industrial applications. Your choice depends on the application environment, surface type, and desired durability, with pressure sensitive labels offering quick, easy application and heat sensitive labels delivering enhanced resistance to heat and moisture. Understanding these differences ensures you select the right label type to maximize product identification and longevity.

Pressure Sensitive vs Heat Sensitive Labels Infographic

libmatt.com

libmatt.com