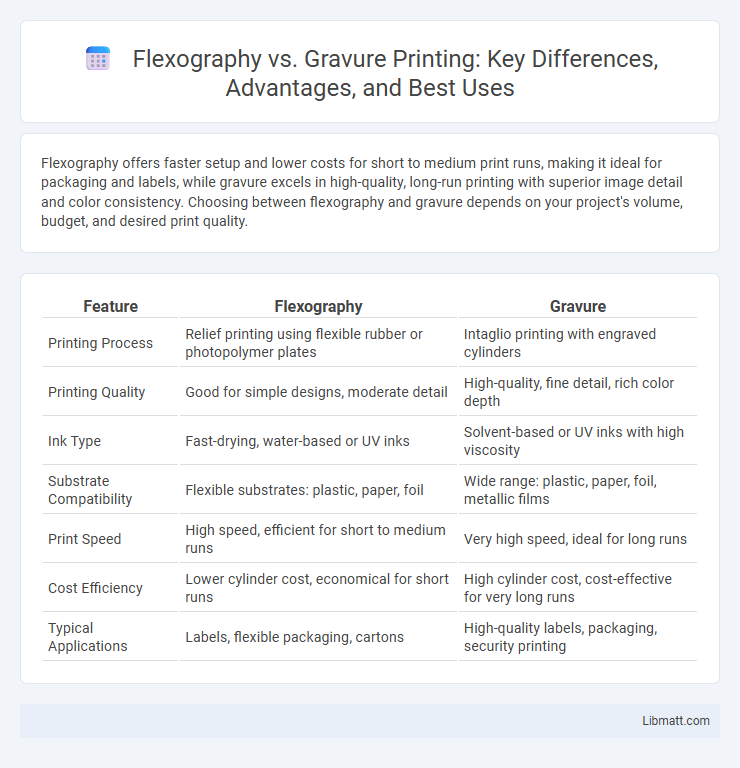

Flexography offers faster setup and lower costs for short to medium print runs, making it ideal for packaging and labels, while gravure excels in high-quality, long-run printing with superior image detail and color consistency. Choosing between flexography and gravure depends on your project's volume, budget, and desired print quality.

Table of Comparison

| Feature | Flexography | Gravure |

|---|---|---|

| Printing Process | Relief printing using flexible rubber or photopolymer plates | Intaglio printing with engraved cylinders |

| Printing Quality | Good for simple designs, moderate detail | High-quality, fine detail, rich color depth |

| Ink Type | Fast-drying, water-based or UV inks | Solvent-based or UV inks with high viscosity |

| Substrate Compatibility | Flexible substrates: plastic, paper, foil | Wide range: plastic, paper, foil, metallic films |

| Print Speed | High speed, efficient for short to medium runs | Very high speed, ideal for long runs |

| Cost Efficiency | Lower cylinder cost, economical for short runs | High cylinder cost, cost-effective for very long runs |

| Typical Applications | Labels, flexible packaging, cartons | High-quality labels, packaging, security printing |

Introduction to Flexography and Gravure

Flexography utilizes flexible relief plates and fast-drying inks, making it ideal for high-volume packaging and label printing with quick turnaround times. Gravure employs engraved cylinders to transfer ink, producing consistent, high-quality images suitable for long runs and fine details in magazines or catalogs. Your choice depends on print volume, image quality needs, and substrate type.

Historical Development of Printing Methods

Flexography emerged in the early 20th century as a modern adaptation of letterpress printing, using flexible relief plates and fast-drying inks to meet the growing demands of packaging and label industries. Gravure printing dates back to the 19th century, evolving from intaglio techniques with engraved cylinders that allowed for high-speed, high-quality reproduction of fine details on large runs, especially in magazines and wallpaper production. Both methods advanced through technological innovations in plate making and ink formulation, establishing their distinct niches within industrial printing.

Flexography: An Overview

Flexography employs flexible relief plates made from rubber or photopolymer to transfer ink onto various substrates, excelling in packaging and label printing. Its fast-drying, water-based inks enable high-speed production with consistent quality on materials such as plastic, foil, and paper. The process offers cost-effective short-to-medium run print jobs, making it versatile for diverse commercial applications.

Gravure Printing: An Overview

Gravure printing involves engraving images onto a cylinder, allowing for high-quality, consistent output ideal for large-volume runs such as magazines, packaging, and labels. This method excels in producing rich colors and fine details, making it a preferred choice for complex, high-resolution printing projects. Your printing needs benefit from gravure's durability and efficiency, especially when long print runs and superior image fidelity are essential.

Key Differences Between Flexography and Gravure

Flexography utilizes flexible relief plates and fast-drying water-based inks, making it ideal for packaging materials with shorter print runs, while gravure employs engraved cylinders and solvent-based inks, excelling in high-quality, long-run printing such as magazines or labels. Flexography offers quicker setup times and lower plate costs, whereas gravure delivers superior image quality and consistent color density over large print volumes. Your choice between flexography and gravure should consider factors like print run length, substrate type, and desired print quality.

Print Quality Comparison

Flexography offers moderate print quality suitable for packaging and labels with clean edges and vibrant colors, while gravure excels in achieving superior image detail and consistency through its engraved cylinders. Gravure provides higher resolution and smoother gradients, making it ideal for high-volume print runs requiring fine detail, such as magazines and packaging with photographic images. The choice depends on balancing cost-efficiency in flexography against the premium print quality and durability of gravure.

Cost and Production Efficiency

Flexography offers lower initial setup costs and faster plate production, making it cost-effective for short to medium print runs and flexible packaging. Gravure involves higher setup expenses due to engraving cylinders but excels in high-volume printing with superior image quality and consistent production efficiency over large runs. Your choice depends on balancing budget constraints with required print volume and quality standards.

Substrate Versatility and Ink Compatibility

Flexography offers superior substrate versatility, effectively printing on a wide range of materials including paper, plastic films, metallic substrates, and corrugated boards. Gravure excels in ink compatibility, capable of handling high-viscosity inks and producing rich, consistent color density on smooth surfaces like coated papers and foils. Both methods serve distinct market needs with flexography favored for flexible packaging and gravure preferred for high-quality decorative applications.

Industry Applications and Use Cases

Flexography dominates packaging industries such as food, pharmaceuticals, and labels due to its fast-drying inks and adaptability to various substrates like plastic, foil, and paper. Gravure excels in high-volume printing for magazines, catalogs, and decorative laminates, offering superior image quality and color consistency. Your choice between flexography and gravure depends on factors like print run length, substrate type, and quality requirements specific to these industrial applications.

Choosing the Right Printing Method

Choosing the right printing method between Flexography and Gravure depends on your specific project requirements such as print quality, volume, and substrate type. Flexography offers fast production speeds and cost-effective solutions for short to medium runs, excelling in packaging materials like plastic, paper, and foil. Gravure provides superior image quality and durability, making it ideal for long runs and high-fidelity prints on flexible packaging and labels.

Flexography vs Gravure Infographic

libmatt.com

libmatt.com