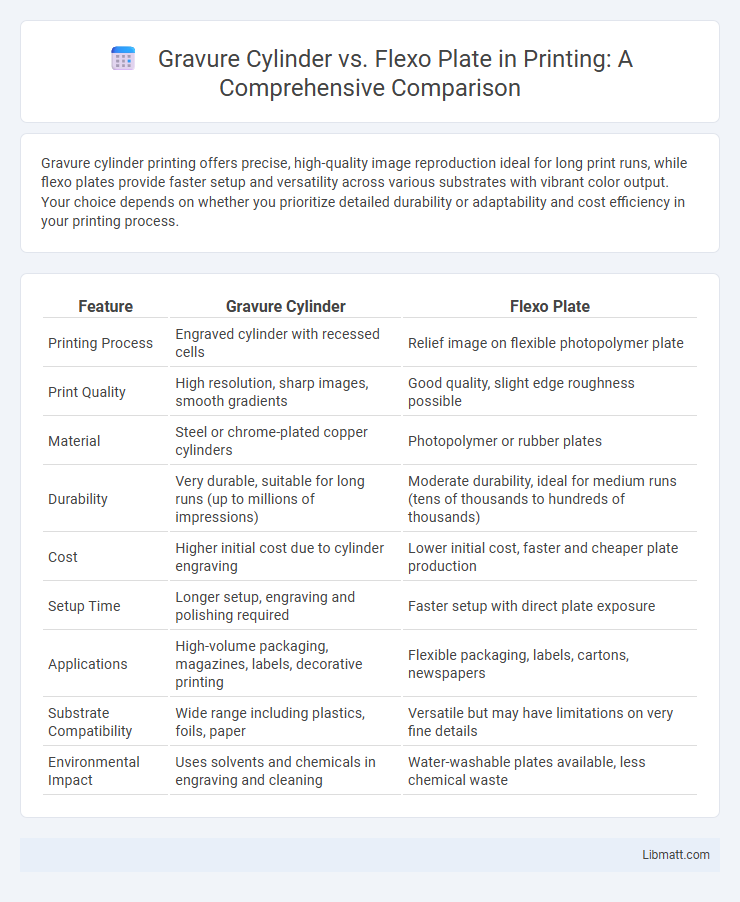

Gravure cylinder printing offers precise, high-quality image reproduction ideal for long print runs, while flexo plates provide faster setup and versatility across various substrates with vibrant color output. Your choice depends on whether you prioritize detailed durability or adaptability and cost efficiency in your printing process.

Table of Comparison

| Feature | Gravure Cylinder | Flexo Plate |

|---|---|---|

| Printing Process | Engraved cylinder with recessed cells | Relief image on flexible photopolymer plate |

| Print Quality | High resolution, sharp images, smooth gradients | Good quality, slight edge roughness possible |

| Material | Steel or chrome-plated copper cylinders | Photopolymer or rubber plates |

| Durability | Very durable, suitable for long runs (up to millions of impressions) | Moderate durability, ideal for medium runs (tens of thousands to hundreds of thousands) |

| Cost | Higher initial cost due to cylinder engraving | Lower initial cost, faster and cheaper plate production |

| Setup Time | Longer setup, engraving and polishing required | Faster setup with direct plate exposure |

| Applications | High-volume packaging, magazines, labels, decorative printing | Flexible packaging, labels, cartons, newspapers |

| Substrate Compatibility | Wide range including plastics, foils, paper | Versatile but may have limitations on very fine details |

| Environmental Impact | Uses solvents and chemicals in engraving and cleaning | Water-washable plates available, less chemical waste |

Introduction to Gravure Cylinder and Flexo Plate

Gravure cylinders and flexo plates serve as essential printing components in high-quality packaging and label production. Gravure cylinders use engraved cells to transfer ink with precision, ideal for long runs and fine details, while flexo plates utilize raised surfaces made from photopolymer or rubber materials, offering versatility in substrate compatibility and faster turnaround. Your choice between these depends on production volume, print quality requirements, and the types of materials you are working with.

Basic Principles of Gravure and Flexo Printing

Gravure printing uses engraved cylinders to transfer ink onto substrates through recessed cells, providing high-resolution and consistent ink layers ideal for detailed images and long print runs. Flexo printing employs flexible relief plates that apply ink to the raised surfaces, enabling fast drying and versatility across various packaging materials. Both techniques rely on precise ink transfer but differ significantly in plate composition, ink viscosity, and print quality characteristics.

Material Composition: Gravure Cylinders vs Flexo Plates

Gravure cylinders are typically made from engraved copper or chrome-plated steel, offering high durability and precise image reproduction due to their hardened surfaces. Flexo plates are composed of photopolymer materials that are flexible, allowing for easier mounting on printing cylinders and adaptability to uneven surfaces. Your choice between gravure and flexo depends largely on the desired print quality and the substrate compatibility linked to these distinct material compositions.

Image Reproduction Quality Comparison

Gravure cylinders deliver superior image reproduction quality with fine detail and smooth tonal gradients due to their engraved cells, enabling high-resolution printing ideal for photographic and complex images. Flexo plates, constructed from flexible photopolymer, offer good image quality suitable for simpler designs and solid colors but often lack the depth and precision of gravure. The microscopic cell structure in gravure ensures consistent ink transfer and sharper image clarity compared to the relief-based flexo plates.

Cost Analysis: Initial Investment and Operational Expenses

Gravure cylinders require a higher initial investment due to expensive engraving processes and durable cylinder materials, while flexo plates are more cost-effective upfront with simpler, less costly manufacturing. Operational expenses for gravure include maintenance of cylinders and higher ink consumption, whereas flexo offers lower maintenance costs and efficient ink usage, reducing ongoing spending. Overall, flexo plates present a more budget-friendly option for short to medium print runs, while gravure cylinders are cost-efficient for large volume production despite higher upfront costs.

Print Speed and Production Efficiency

Gravure cylinders enable higher print speeds, often exceeding 2,000 feet per minute, due to their engraved cells that hold and transfer ink efficiently, resulting in consistent high-quality output. Flexo plates generally operate at lower speeds, around 1,000 to 1,500 feet per minute, but offer faster setup times and easier plate changes, enhancing overall production flexibility. While gravure excels in large-volume runs with superior speed, flexo plates optimize production efficiency for shorter runs and frequent job changes through rapid preparation and lower initial costs.

Application Suitability and Versatility

Gravure cylinders excel in high-volume printing with superior image quality, making them ideal for packaging applications such as labels, decorative laminates, and flexible films. Flexo plates offer greater versatility across a broader range of substrates, including corrugated board, paper, and plastic films, suitable for short to medium runs. The choice between gravure and flexo depends on production scale, substrate compatibility, and print detail requirements.

Durability and Longevity of Printing Elements

Gravure cylinders are renowned for their superior durability and long-lasting performance, capable of withstanding extensive print runs without significant wear due to their etched metal surface. Flexo plates, made from photopolymer materials, typically have a shorter lifespan and may degrade faster under high-volume printing conditions, leading to frequent replacements. The robust construction of gravure cylinders ensures consistent print quality over time, making them ideal for long-term, high-demand applications.

Environmental Impact and Sustainability

Gravure cylinders typically require more energy and solvent use during manufacturing, leading to a higher environmental footprint compared to flexo plates, which are produced using photopolymer materials and water-based processes that offer improved sustainability. Flexo plates generate less waste and allow for easier recycling or disposal, reducing your overall environmental impact in printing operations. Choosing flexo technology supports eco-friendly practices by minimizing emissions and promoting resource efficiency in packaging and label production.

Choosing the Right Technology for Your Printing Needs

Gravure cylinders offer exceptional detail and durability for high-volume printing, making them ideal for long runs of packaging and labels, while flexo plates provide cost-effective flexibility and quick turnaround for shorter runs and diverse substrates. Understanding your print volume, substrate type, and budget will guide your decision between gravure's precision and flexo's adaptability. You benefit by selecting the technology that aligns with your production scale and quality expectations, ensuring optimal efficiency and print performance.

Gravure Cylinder vs Flexo Plate Infographic

libmatt.com

libmatt.com