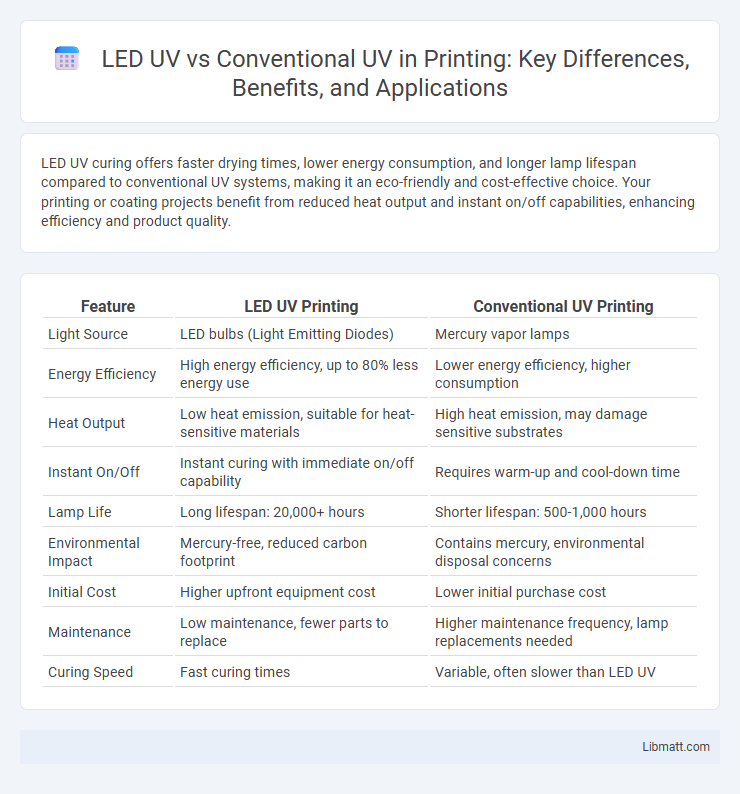

LED UV curing offers faster drying times, lower energy consumption, and longer lamp lifespan compared to conventional UV systems, making it an eco-friendly and cost-effective choice. Your printing or coating projects benefit from reduced heat output and instant on/off capabilities, enhancing efficiency and product quality.

Table of Comparison

| Feature | LED UV Printing | Conventional UV Printing |

|---|---|---|

| Light Source | LED bulbs (Light Emitting Diodes) | Mercury vapor lamps |

| Energy Efficiency | High energy efficiency, up to 80% less energy use | Lower energy efficiency, higher consumption |

| Heat Output | Low heat emission, suitable for heat-sensitive materials | High heat emission, may damage sensitive substrates |

| Instant On/Off | Instant curing with immediate on/off capability | Requires warm-up and cool-down time |

| Lamp Life | Long lifespan: 20,000+ hours | Shorter lifespan: 500-1,000 hours |

| Environmental Impact | Mercury-free, reduced carbon footprint | Contains mercury, environmental disposal concerns |

| Initial Cost | Higher upfront equipment cost | Lower initial purchase cost |

| Maintenance | Low maintenance, fewer parts to replace | Higher maintenance frequency, lamp replacements needed |

| Curing Speed | Fast curing times | Variable, often slower than LED UV |

Introduction to UV Curing Technologies

UV curing technologies utilize ultraviolet light to rapidly dry or cure coatings, inks, and adhesives. LED UV systems offer energy-efficient, longer-lasting light sources with specific wavelength control, while conventional UV lamps rely on mercury vapor bulbs that generate broader spectrum UV light but consume more power and produce more heat. Your choice between LED UV and conventional UV impacts environmental sustainability, curing speed, and maintenance costs in industrial applications.

Fundamentals of Conventional UV Systems

Conventional UV systems utilize mercury vapor lamps to emit ultraviolet light for curing coatings, inks, and adhesives, with a broad spectrum including UVA, UVB, and UVC wavelengths. These systems rely on heat generated during operation, requiring warm-up and cool-down periods to maintain lamp stability and performance. Your choice between LED UV and conventional UV should consider factors like energy consumption, lamp lifespan, and the specific curing needs of your application.

What is LED UV Technology?

LED UV technology uses light-emitting diodes to cure ultraviolet inks and coatings faster and more efficiently than conventional mercury vapor UV lamps. This method provides instant on/off capabilities, longer lifespan, and reduced energy consumption, resulting in lower operational costs and environmental impact. Your printing or coating processes benefit from improved productivity and consistent curing quality with LED UV technology.

Energy Efficiency: LED UV vs Conventional UV

LED UV technology offers significantly higher energy efficiency compared to conventional UV systems, consuming up to 80% less power while maintaining effective curing performance. Your printing processes benefit from reduced electricity costs and lower heat output, enhancing equipment longevity and workspace comfort. Conventional UV lamps, which rely on mercury vapor, generate more heat and waste energy during startup and operation, leading to higher energy expenses and environmental impact.

Curing Performance and Speed Comparison

LED UV curing offers faster polymerization times compared to conventional UV lamps due to higher energy efficiency and instant on/off capabilities. Conventional UV lamps rely on mercury vapor and often require warm-up periods, resulting in slower curing speeds and less consistent output. LED UV technology provides more precise wavelength targeting, leading to improved curing performance on a variety of substrates with reduced energy consumption.

Equipment Lifespan and Maintenance Needs

LED UV curing systems offer significantly longer equipment lifespan, often exceeding 20,000 hours, compared to conventional UV lamps which typically last around 1,000 to 2,000 hours. Maintenance requirements for LED UV units are minimal due to their solid-state design, eliminating the need for frequent lamp replacements and reducing downtime. Conventional UV systems demand regular lamp changes and reflector cleaning, increasing operational costs and maintenance frequency.

Environmental Impact and Safety Considerations

LED UV curing emits significantly less hazardous waste and consumes up to 90% less energy compared to conventional UV systems, reducing your carbon footprint. Unlike traditional UV lamps that contain mercury, LED UV lamps are mercury-free, enhancing environmental safety and simplifying disposal. The lower heat output of LED UV also minimizes exposure to harmful UV radiation, improving workplace safety for operators.

Application Flexibility and Material Compatibility

LED UV technology offers greater application flexibility due to its instant on/off capability and precise wavelength control, enabling efficient curing of a broader range of materials compared to conventional UV lamps. Your processes benefit from LED UV's lower heat output, reducing the risk of damaging heat-sensitive substrates and expanding compatibility with delicate or heat-sensitive materials. Conventional UV lamps, while effective for many applications, often have limited spectral output and heat generation that restricts their use with certain plastics, coatings, or adhesives.

Cost Analysis: Initial Investment and Operational Expenses

LED UV systems typically require a higher initial investment compared to conventional UV setups due to advanced semiconductor technology and longer lifespan components. Operational expenses for LED UV are significantly lower because of reduced energy consumption, minimal heat output, and less frequent replacement of bulbs, translating to savings in electricity and maintenance costs. Conventional UV systems, while cheaper upfront, incur higher ongoing costs from bulb replacements and increased energy usage, impacting overall long-term expenditure.

Future Trends in UV Curing Technologies

LED UV curing technology offers longer lamp life and lower energy consumption compared to conventional mercury-based UV lamps, driving its adoption in industrial applications. Future trends highlight the integration of LED UV systems with advanced automation and smart sensors to improve curing precision and process efficiency. Continued advancements in LED wavelength customization and intensity control are expected to expand the scope of UV curing in flexible electronics and rapid prototyping.

LED UV vs conventional UV Infographic

libmatt.com

libmatt.com