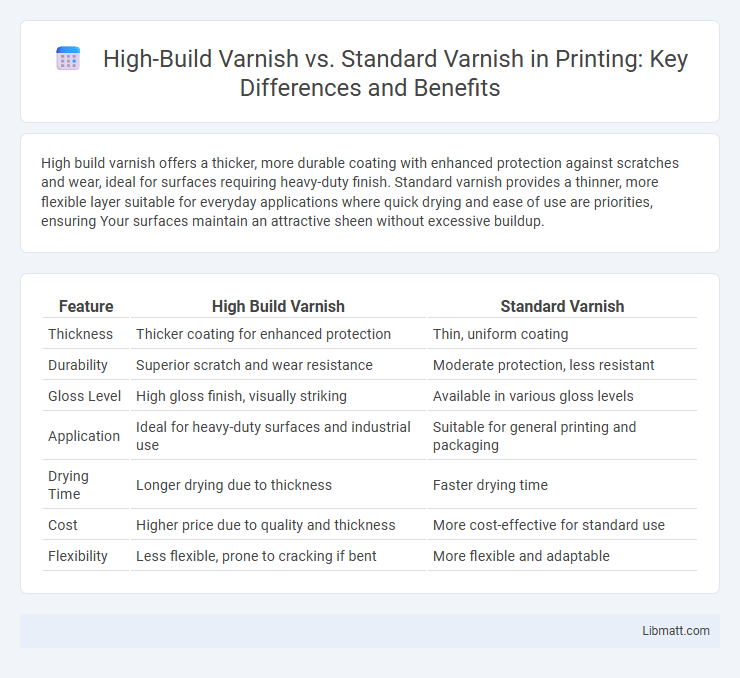

High build varnish offers a thicker, more durable coating with enhanced protection against scratches and wear, ideal for surfaces requiring heavy-duty finish. Standard varnish provides a thinner, more flexible layer suitable for everyday applications where quick drying and ease of use are priorities, ensuring Your surfaces maintain an attractive sheen without excessive buildup.

Table of Comparison

| Feature | High Build Varnish | Standard Varnish |

|---|---|---|

| Thickness | Thicker coating for enhanced protection | Thin, uniform coating |

| Durability | Superior scratch and wear resistance | Moderate protection, less resistant |

| Gloss Level | High gloss finish, visually striking | Available in various gloss levels |

| Application | Ideal for heavy-duty surfaces and industrial use | Suitable for general printing and packaging |

| Drying Time | Longer drying due to thickness | Faster drying time |

| Cost | Higher price due to quality and thickness | More cost-effective for standard use |

| Flexibility | Less flexible, prone to cracking if bent | More flexible and adaptable |

Introduction to Varnishes: Purpose and Types

High build varnish provides a thicker, more durable coating compared to standard varnish, offering enhanced protection and a smoother finish on surfaces like wood and metal. Standard varnish creates a thinner, often clearer layer ideal for light protection and preserving the natural appearance of materials. Both types serve to protect surfaces from damage, UV rays, and moisture, but selection depends on the desired finish thickness and durability requirements.

What Is High Build Varnish?

High build varnish is a thick, durable coating designed to create a smooth, glossy finish by filling surface imperfections more effectively than standard varnish. It typically offers enhanced protection against scratches, UV rays, and moisture, making it ideal for high-traffic or exterior surfaces. Compared to standard varnish, high build varnish requires fewer coats to achieve a robust, professional-quality finish.

What Is Standard Varnish?

Standard varnish is a clear protective coating commonly applied to wood, metal, and other surfaces to enhance durability and appearance. It typically offers moderate thickness and dries faster, providing a smooth, glossy, or satin finish while protecting against moisture, UV rays, and wear. Your choice between standard and high build varnish depends on the desired thickness, surface protection, and application requirements.

Key Differences: High Build vs Standard Varnish

High build varnish offers a thicker, more durable coating compared to standard varnish, providing enhanced protection against scratches and environmental damage. It requires fewer coats to achieve a smooth, glossy finish, making it ideal for surfaces needing robust wear resistance. Standard varnish, while thinner and less durable, dries faster and is suitable for lighter-duty applications where rapid curing is preferred.

Application Processes Compared

High build varnish requires fewer coats due to its thicker consistency, allowing for a quicker application process and enhanced surface protection with minimal sanding between layers. Standard varnish typically needs multiple thin coats with careful drying time, which can prolong the overall application time and may require more surface preparation. Your choice between these varnishes depends on the desired durability and time efficiency for the project.

Durability and Protection Factors

High build varnish offers superior durability and protection due to its thicker application, providing enhanced resistance to scratches, chemicals, and environmental wear compared to standard varnish. Its robust film layer effectively shields surfaces from moisture, UV damage, and abrasion, extending the lifespan of your wood or painted surfaces. Choosing high build varnish ensures better long-term protection, especially in heavy-use or outdoor environments.

Aesthetic Results and Finish Quality

High build varnish offers superior aesthetic results by creating a thicker, more durable coating that enhances surface depth and gloss, making your woodwork or furniture appear richer and more polished. It effectively hides minor imperfections and provides a smoother, flawless finish compared to standard varnish, which is thinner and may highlight surface irregularities. Choosing high build varnish significantly improves finish quality, delivering longer-lasting protection and a professional-grade appearance.

Suitable Use Cases for High Build Varnish

High build varnish is ideal for surfaces requiring enhanced durability and protection, such as wooden furniture, cabinets, and floors exposed to heavy wear and tear. Its thicker layer provides superior resistance to scratches, moisture, and UV damage, making it suitable for both indoor and outdoor applications. You can rely on high build varnish to restore and protect older surfaces with imperfections due to its excellent leveling properties.

Ideal Applications for Standard Varnish

Standard varnish is ideal for interior wood surfaces such as furniture, trim, and cabinetry where moderate durability and a smooth finish are essential. It provides sufficient protection against moisture, wear, and UV damage for areas with light to moderate use. This varnish type is suitable for residential and commercial environments that require aesthetic enhancement without the need for extra thickness or heavy-duty protection.

Choosing the Right Varnish for Your Project

High build varnish offers superior thickness and durability, making it ideal for projects requiring extra protection against wear and surface imperfections. Standard varnish provides a thinner, more flexible coating suited for smoother surfaces and lighter use. Choosing the right varnish depends on your project's needs for durability, texture, and finish quality to ensure lasting results.

High build varnish vs standard varnish Infographic

libmatt.com

libmatt.com