Polyester mesh offers excellent UV resistance and retains shape well in outdoor conditions, making it ideal for applications like screens and sportswear, while nylon mesh provides superior strength, elasticity, and moisture-wicking properties, which are perfect for activewear and heavy-duty uses. Understanding the differences between polyester mesh and nylon mesh helps you choose the right material that balances durability, comfort, and environmental exposure.

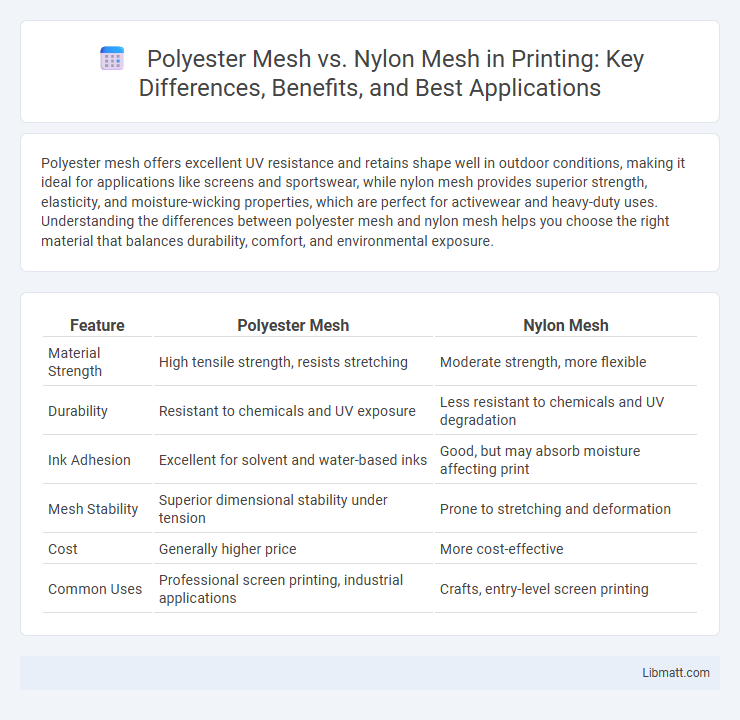

Table of Comparison

| Feature | Polyester Mesh | Nylon Mesh |

|---|---|---|

| Material Strength | High tensile strength, resists stretching | Moderate strength, more flexible |

| Durability | Resistant to chemicals and UV exposure | Less resistant to chemicals and UV degradation |

| Ink Adhesion | Excellent for solvent and water-based inks | Good, but may absorb moisture affecting print |

| Mesh Stability | Superior dimensional stability under tension | Prone to stretching and deformation |

| Cost | Generally higher price | More cost-effective |

| Common Uses | Professional screen printing, industrial applications | Crafts, entry-level screen printing |

Introduction to Polyester Mesh and Nylon Mesh

Polyester mesh features durable synthetic fibers known for excellent resistance to UV rays, moisture, and chemicals, making it ideal for outdoor applications and heavy-duty use. Nylon mesh offers superior elasticity and abrasion resistance, providing flexibility and strength suitable for athletic gear and industrial purposes. Understanding the distinct properties of polyester and nylon mesh helps you select the right material tailored to your specific performance and environmental needs.

Composition and Manufacturing Processes

Polyester mesh is made from polyethylene terephthalate fibers, produced through a polymerization process followed by extrusion and weaving, which creates a durable and weather-resistant fabric. Nylon mesh consists of polyamide fibers formed by a condensation polymerization method and spun into fine filaments before weaving, resulting in a lightweight and elastic material. Manufacturing techniques for polyester mesh emphasize UV resistance and dimensional stability, whereas nylon mesh production focuses on strength and abrasion resistance.

Durability and Strength Comparison

Polyester mesh offers higher resistance to UV rays and moisture, making it more durable for outdoor applications compared to nylon mesh, which tends to degrade faster when exposed to sunlight. Nylon mesh exhibits greater elasticity and tensile strength, allowing it to withstand heavier loads and frequent stretching without tearing. Choose polyester mesh for long-lasting durability in harsh environments, while nylon mesh is ideal for applications requiring flexibility and toughness.

Breathability and Moisture Management

Polyester mesh offers superior breathability and moisture-wicking properties compared to nylon mesh, making it ideal for activewear and outdoor gear. Its hydrophobic fibers repel water, ensuring faster drying times and enhanced comfort during intense physical activities. Nylon mesh, while durable, tends to absorb more moisture, which can reduce ventilation and increase drying duration.

Weight and Flexibility Differences

Polyester mesh generally offers a lighter weight compared to nylon mesh, making it ideal for applications requiring minimal bulk and enhanced breathability. Nylon mesh tends to be more flexible, providing better stretch and durability under tension, which suits dynamic or high-impact uses. Both materials vary in density and weave, impacting their respective strength-to-weight ratios and flexibility profiles for versatile performance needs.

Resistance to Chemicals and Abrasion

Polyester mesh offers superior resistance to chemicals such as acids, alkalis, and solvents, making it an ideal choice for harsh industrial environments. Nylon mesh provides excellent abrasion resistance and tensile strength, but it can degrade when exposed to strong chemicals. When selecting mesh material, consider your specific chemical exposure and wear conditions to ensure optimal durability and performance.

UV and Heat Resistance

Polyester mesh offers superior UV resistance, maintaining strength and color when exposed to prolonged sunlight, making it ideal for outdoor applications. Nylon mesh, while strong and flexible, tends to degrade faster under UV exposure and is less heat resistant compared to polyester. In high-temperature environments, polyester mesh retains durability, whereas nylon can weaken and lose shape more quickly.

Typical Applications and Industry Uses

Polyester mesh is widely used in industrial filtration, screen printing, and agricultural applications due to its excellent resistance to UV, chemicals, and moisture. Nylon mesh is favored in marine environments, food processing, and sportswear for its superior elasticity, abrasion resistance, and ability to dry quickly. Choosing the right mesh depends on your specific needs for durability, flexibility, and environmental exposure.

Cost Considerations and Availability

Polyester mesh typically offers a more cost-effective option compared to nylon mesh due to its widespread availability and lower production expenses. Nylon mesh, while often priced higher, provides enhanced durability and elasticity, justifying the investment for applications requiring greater strength and flexibility. When choosing between polyester and nylon mesh, your decision should balance budget constraints with the required performance and accessibility of materials in your area.

Choosing the Right Mesh for Your Needs

Polyester mesh offers superior UV resistance and durability, making it ideal for outdoor applications such as shade sails and sports nets. Nylon mesh provides greater elasticity and strength, suitable for heavy-duty uses like industrial filtration and camping gear. Selecting the right mesh depends on factors like weather exposure, stretch tolerance, and specific use requirements, ensuring optimal performance and longevity.

Polyester Mesh vs Nylon Mesh Infographic

libmatt.com

libmatt.com