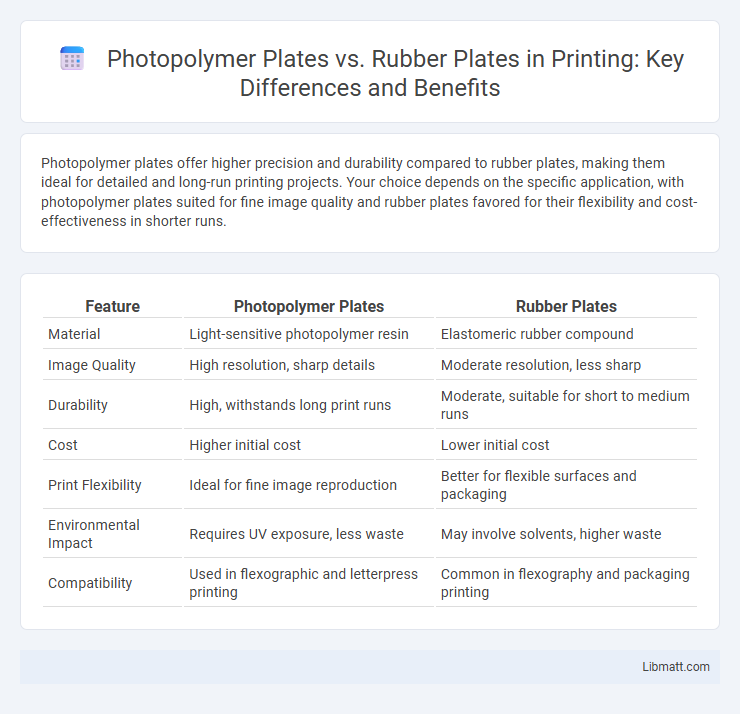

Photopolymer plates offer higher precision and durability compared to rubber plates, making them ideal for detailed and long-run printing projects. Your choice depends on the specific application, with photopolymer plates suited for fine image quality and rubber plates favored for their flexibility and cost-effectiveness in shorter runs.

Table of Comparison

| Feature | Photopolymer Plates | Rubber Plates |

|---|---|---|

| Material | Light-sensitive photopolymer resin | Elastomeric rubber compound |

| Image Quality | High resolution, sharp details | Moderate resolution, less sharp |

| Durability | High, withstands long print runs | Moderate, suitable for short to medium runs |

| Cost | Higher initial cost | Lower initial cost |

| Print Flexibility | Ideal for fine image reproduction | Better for flexible surfaces and packaging |

| Environmental Impact | Requires UV exposure, less waste | May involve solvents, higher waste |

| Compatibility | Used in flexographic and letterpress printing | Common in flexography and packaging printing |

Introduction to Printing Plate Technologies

Photopolymer plates offer higher precision and durability compared to traditional rubber plates in printing, utilizing light-sensitive materials that harden upon exposure to UV light. Rubber plates provide flexibility and cost-effectiveness for short-run jobs but lack the fine detail reproduction and repeatability of photopolymer plates. Your choice between these two technologies depends on print quality requirements, budget constraints, and production volume.

Overview of Photopolymer Plates

Photopolymer plates offer high-resolution printing with superior image quality and durability compared to rubber plates. These plates are made from light-sensitive polymers that harden when exposed to UV light, enabling precise and efficient production for flexographic printing. Your printing process benefits from faster setup times and consistent results, making photopolymer plates ideal for detailed and high-volume print jobs.

Overview of Rubber Plates

Rubber plates are widely used in flexographic printing for their durability and flexibility, ideal for printing on uneven surfaces like corrugated boxes. Their natural elasticity allows for consistent ink transfer and excellent resistance to abrasion and chemicals. Compared to photopolymer plates, rubber plates offer superior performance in high-volume packaging applications but may lack the fine detail reproduction achievable with photopolymer technology.

Key Material Differences

Photopolymer plates consist of a light-sensitive polymer that hardens when exposed to UV light, providing precise image reproduction and high durability. Rubber plates are made from elastomeric compounds, offering greater flexibility and resilience for low-pressure printing applications but with less fine detail accuracy. The photopolymer's rigidity ensures sharp printing quality, whereas rubber plates excel in conforming to uneven surfaces and are ideal for packaging or textured substrates.

Image Quality and Resolution

Photopolymer plates offer superior image quality and higher resolution compared to rubber plates due to their ability to reproduce fine details with sharpness and precision. Your printing process benefits from photopolymer's consistent surface hardness, which ensures crisp and clear images, especially in high-definition printing applications. Rubber plates, while durable, tend to have lower resolution capabilities, making photopolymer plates the preferred choice for detailed and high-quality print jobs.

Durability and Longevity

Photopolymer plates offer superior durability compared to rubber plates due to their resistance to chemical corrosion and consistent performance under high-press conditions. These plates typically last longer, maintaining image quality over extended print runs, making them cost-effective for large volumes. Rubber plates, while flexible and good for short runs, tend to wear out faster and degrade in detail with repeated use.

Cost Comparison

Photopolymer plates generally have a higher initial cost compared to rubber plates due to advanced materials and technology used in their production. However, photopolymer plates offer greater durability, longer lifespan, and enhanced print quality, which can reduce overall expenses in high-volume printing operations. Rubber plates provide a more affordable upfront option but may require more frequent replacement, leading to increased long-term costs.

Environmental Impact

Photopolymer plates generate less waste and use fewer chemicals compared to traditional rubber plates, making them more eco-friendly in printing processes. Their production involves lower energy consumption and reduced emissions, contributing to a smaller carbon footprint. Choosing photopolymer plates can help Your printing operations minimize environmental impact while maintaining high-quality output.

Suitable Printing Applications

Photopolymer plates excel in high-resolution printing applications requiring fine detail, such as packaging, labels, and flexible materials, due to their precision and durability. Rubber plates are better suited for printing on rough, textured surfaces and materials like corrugated cardboard, offering flexibility and resistance to wear in traditional letterpress and flexographic processes. Your choice depends on the substrate and print quality needed for your specific project.

Choosing the Right Plate for Your Needs

Photopolymer plates offer superior resolution and durability, making them ideal for high-quality printing and long print runs, while rubber plates provide greater flexibility and cost-effectiveness for shorter runs or packaging applications. Consider the type of substrate, print volume, and desired detail when selecting between photopolymer and rubber plates. Balancing factors such as durability, cost, and application-specific requirements ensures the optimal plate choice for your printing needs.

Photopolymer plates vs rubber plates Infographic

libmatt.com

libmatt.com