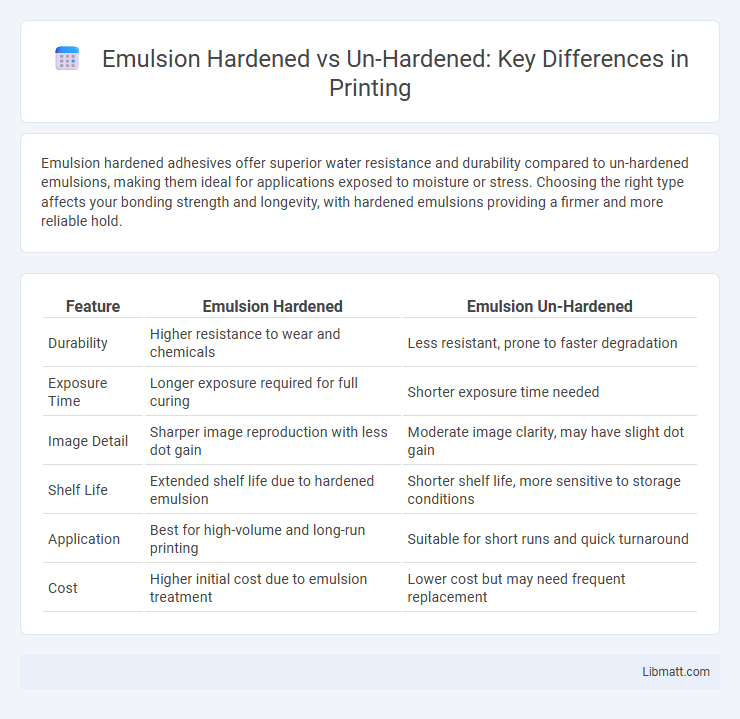

Emulsion hardened adhesives offer superior water resistance and durability compared to un-hardened emulsions, making them ideal for applications exposed to moisture or stress. Choosing the right type affects your bonding strength and longevity, with hardened emulsions providing a firmer and more reliable hold.

Table of Comparison

| Feature | Emulsion Hardened | Emulsion Un-Hardened |

|---|---|---|

| Durability | Higher resistance to wear and chemicals | Less resistant, prone to faster degradation |

| Exposure Time | Longer exposure required for full curing | Shorter exposure time needed |

| Image Detail | Sharper image reproduction with less dot gain | Moderate image clarity, may have slight dot gain |

| Shelf Life | Extended shelf life due to hardened emulsion | Shorter shelf life, more sensitive to storage conditions |

| Application | Best for high-volume and long-run printing | Suitable for short runs and quick turnaround |

| Cost | Higher initial cost due to emulsion treatment | Lower cost but may need frequent replacement |

Introduction to Emulsion Hardening

Emulsion hardening improves the durability and stability of emulsions by forming a robust interfacial film around dispersed droplets, preventing coalescence and phase separation. This process enhances the mechanical properties and shelf-life of cosmetic, pharmaceutical, and food products by increasing resistance to temperature changes and mechanical stress. Un-hardened emulsions lack this protective film, resulting in lower stability and a higher tendency for droplet aggregation and breakdown over time.

Definition of Hardened Emulsion

Hardened emulsion is a type of photographic emulsion in which silver halide crystals have been chemically treated or physically altered to increase their resistance to physical and chemical damage during processing. This hardening process improves the emulsion's durability, preventing issues like swelling or abrasion when exposed to developer and fixer solutions. Un-hardened emulsion lacks this treatment, making it more susceptible to damage but sometimes preferable for applications requiring softer tonal gradations and easier retouching.

Definition of Un-Hardened Emulsion

Un-hardened emulsion refers to a type of photographic emulsion that remains soft and sensitive until it undergoes a chemical hardening process, which improves durability and resistance to physical damage. This emulsion allows for easy manipulation during development but is more vulnerable to scratches and contamination compared to hardened emulsions. Understanding the distinction helps you select the appropriate emulsion type based on your specific photographic or industrial needs.

Key Differences Between Hardened and Un-Hardened Emulsions

Hardened emulsions have enhanced chemical resistance and physical durability due to added crosslinking agents, making them ideal for high-resolution printing and prolonged exposure to harsh conditions. Un-hardened emulsions offer faster exposure times and easier reclaiming but lack the durability and chemical resistance, suitable for short-run or less demanding applications. The choice between hardened and un-hardened emulsions depends on factors such as print longevity, detail precision, and exposure requirements.

Chemical Composition and Additives

Emulsion-hardening steels contain alloying elements such as chromium, nickel, and molybdenum that enhance hardness through heat treatment in oil or water-based emulsions, promoting fine carbide distribution and improved wear resistance. Unhardened steels typically lack these specialized additives and have a simpler chemical composition, resulting in lower hardness and wear resistance but increased machinability and toughness. The additives in emulsion-hardened steels enable the formation of a martensitic microstructure, while unhardened steels maintain a predominantly ferritic or pearlitic matrix.

Performance and Stability Comparison

Emulsion hardened formulations exhibit superior performance due to their enhanced chemical stability and resistance to environmental factors like temperature and UV exposure, ensuring longer-lasting durability. Un-hardened emulsions often suffer from phase separation and reduced shelf life, leading to inconsistent application and lower overall effectiveness. You benefit from using emulsion hardened products when consistent performance and long-term stability are crucial for your project.

Applications of Hardened Emulsions

Hardened emulsions are widely used in industrial coatings, adhesives, and construction materials due to their enhanced durability, chemical resistance, and mechanical strength. Applications include protective coatings for metal surfaces, waterproofing membranes, and high-performance adhesives that require long-term stability and toughness. Your projects benefit from using hardened emulsions when exposure to harsh environmental conditions and mechanical stress is a critical factor.

Applications of Un-Hardened Emulsions

Un-hardened emulsions are widely used in applications where flexibility and ease of removal are essential, such as in lithographic printing plates and coating layers for pharmaceutical tablets. These emulsions provide excellent image resolution and quick processing times, making them ideal for short-run printing and temporary surface protection. Your choice of un-hardened emulsions supports efficient production workflows without compromising detail or adaptability.

Advantages and Disadvantages of Each Type

Emulsion hardened drilling fluids provide superior stability and improved shale inhibition, enhancing drilling efficiency and reducing formation damage. However, they tend to be more expensive and require careful handling due to environmental concerns and disposal issues. Un-hardened emulsions are simpler and less costly to manage but offer lower thermal stability and weaker shale inhibition, potentially leading to increased formation swelling and reduced wellbore stability.

Choosing the Right Emulsion for Your Needs

Emulsion hardened films offer increased durability and resistance to scratches, making them ideal for high-volume or detailed screen printing tasks where longevity is critical. Un-hardened emulsions provide easier cleanup and faster exposure times, suitable for short runs or projects requiring frequent stencil changes. Selecting the right emulsion depends on print volume, detail complexity, and desired stencil lifespan to optimize productivity and print quality.

Emulsion hardened vs un-hardened Infographic

libmatt.com

libmatt.com