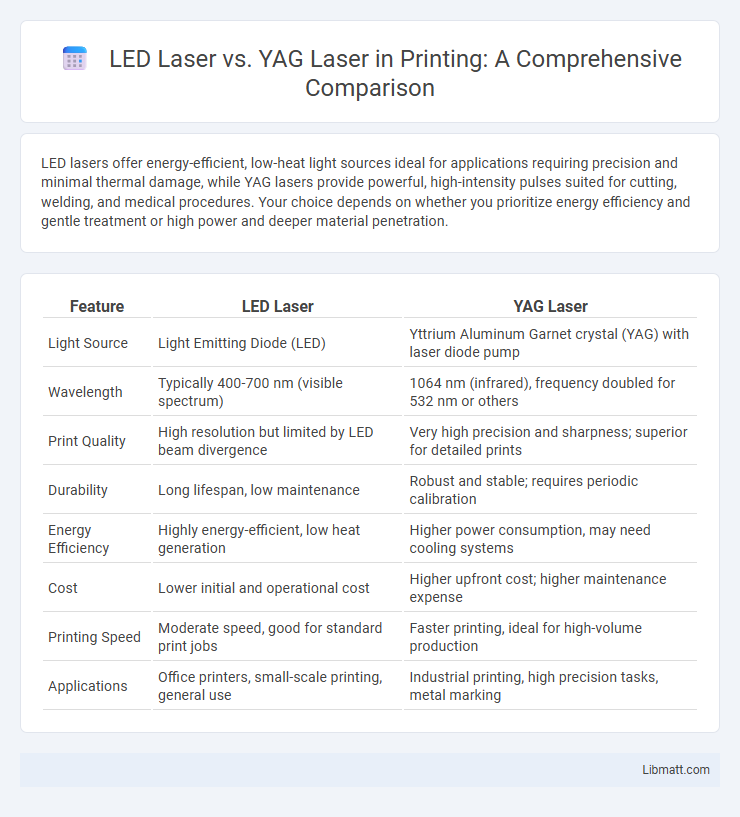

LED lasers offer energy-efficient, low-heat light sources ideal for applications requiring precision and minimal thermal damage, while YAG lasers provide powerful, high-intensity pulses suited for cutting, welding, and medical procedures. Your choice depends on whether you prioritize energy efficiency and gentle treatment or high power and deeper material penetration.

Table of Comparison

| Feature | LED Laser | YAG Laser |

|---|---|---|

| Light Source | Light Emitting Diode (LED) | Yttrium Aluminum Garnet crystal (YAG) with laser diode pump |

| Wavelength | Typically 400-700 nm (visible spectrum) | 1064 nm (infrared), frequency doubled for 532 nm or others |

| Print Quality | High resolution but limited by LED beam divergence | Very high precision and sharpness; superior for detailed prints |

| Durability | Long lifespan, low maintenance | Robust and stable; requires periodic calibration |

| Energy Efficiency | Highly energy-efficient, low heat generation | Higher power consumption, may need cooling systems |

| Cost | Lower initial and operational cost | Higher upfront cost; higher maintenance expense |

| Printing Speed | Moderate speed, good for standard print jobs | Faster printing, ideal for high-volume production |

| Applications | Office printers, small-scale printing, general use | Industrial printing, high precision tasks, metal marking |

Introduction to LED and YAG Lasers

LED lasers utilize light-emitting diodes to produce lower-intensity, broad-spectrum light suitable for applications like phototherapy and low-level laser therapy. YAG lasers, specifically Neodymium-doped Yttrium Aluminum Garnet lasers, emit high-intensity, coherent infrared light ideal for precision tasks such as laser surgery and industrial cutting. Understanding the distinct operational mechanisms and wavelengths of LED and YAG lasers helps you select the appropriate technology for your specific medical or technical needs.

How LED Lasers Work

LED lasers operate by emitting light through electroluminescence, where electrons recombine with holes in a semiconductor material, releasing photons. These lasers typically produce a coherent light at specific wavelengths with high efficiency and low heat output. Unlike YAG lasers, which use crystal mediums and optical pumping, LED lasers offer compactness and energy-saving benefits ideal for precision applications.

Understanding YAG Laser Technology

YAG laser technology operates using a crystal medium doped with yttrium aluminum garnet, producing powerful infrared light commonly used in medical and industrial applications. Unlike LED lasers that emit lower-intensity, broader wavelengths, YAG lasers deliver precise, high-energy pulses ideal for tasks requiring accuracy, such as laser eye surgery or metal cutting. Understanding your choice between LED and YAG lasers depends on the specific energy output and target material, making YAG technology essential when intensity and precision are critical.

Key Differences Between LED and YAG Lasers

LED lasers emit light through light-emitting diodes, producing low-intensity, broad-spectrum illumination ideal for general aesthetic treatments, while YAG lasers generate high-intensity, coherent light at specific wavelengths, making them suitable for precise medical and cosmetic procedures like tattoo removal and skin resurfacing. YAG lasers offer deeper skin penetration and higher energy output compared to LED lasers, enabling targeted treatment of pigmentation, vascular lesions, and hair removal with minimal damage to surrounding tissue. Your choice depends on treatment goals, with LED lasers being safer for surface-level skin enhancement and YAG lasers preferred for aggressive, clinical applications.

Applications of LED Lasers

LED lasers are widely used in applications such as optical communications, biomedical imaging, and environmental sensing due to their efficiency and compact size. Their ability to emit coherent light at specific wavelengths makes them ideal for precise medical diagnostics and treatment procedures. Your choice of LED lasers can enhance performance in areas requiring stable, low-power light sources with high modulation speed.

Applications of YAG Lasers

YAG lasers, particularly the Nd:YAG variant, are widely used in medical procedures such as laser eye surgery, dermatology treatments, and dental applications due to their precision and ability to target deep tissues without damaging surrounding areas. Industrial applications include cutting, welding, and marking metals, where the YAG laser's high power and short pulse duration provide superior control and efficiency. The versatility of YAG lasers in both medical and manufacturing fields stems from their ability to emit infrared light at 1064 nm, enabling effective material interaction and therapeutic outcomes.

Efficacy and Results: LED vs YAG

LED lasers provide effective low-level light therapy that promotes cellular regeneration and reduces inflammation, making them ideal for skin rejuvenation and pain relief with minimal downtime. YAG lasers offer more intense, targeted energy that penetrates deeper tissues, delivering superior results in hair removal, vascular lesion treatment, and tattoo removal due to their ability to break down pigment and stimulate collagen production. Your choice depends on the desired outcome, with YAG lasers excelling in precision and long-term results, while LED lasers offer gentler, cumulative benefits suited for ongoing therapy.

Safety and Side Effects Comparison

LED lasers offer a safer profile with minimal side effects, making them ideal for sensitive skin treatments and prolonged use. YAG lasers, while effective for deeper tissue targeting and pigment reduction, carry a higher risk of burns, hyperpigmentation, and longer recovery times. Your choice between LED and YAG lasers should consider the balance between safety and treatment intensity based on your specific skin needs.

Cost and Accessibility Differences

LED lasers generally have a lower cost and greater accessibility compared to YAG lasers, making them more suitable for routine diagnostic and therapeutic applications. YAG lasers, known for their higher power and precision in medical and industrial uses, typically come with a higher price tag and require specialized training to operate. Your choice depends on balancing initial investment costs with the specific performance needs of your application.

Choosing the Right Laser: LED or YAG?

Choosing the right laser depends on your specific application needs, as LED lasers provide cost-effective, energy-efficient solutions ideal for surface treatments and low-power medical uses, while YAG lasers deliver higher precision and deeper tissue penetration suited for surgical and industrial applications. LED lasers operate at lower intensities and wavelengths typically around 630-670 nm, making them suitable for phototherapy and skin rejuvenation, whereas YAG lasers emit at 1064 nm, enabling effective performance in laser cutting, welding, and tattoo removal. Understanding your treatment goals and material requirements will help you select the optimal laser technology tailored to your procedures and desired outcomes.

LED laser vs YAG laser Infographic

libmatt.com

libmatt.com