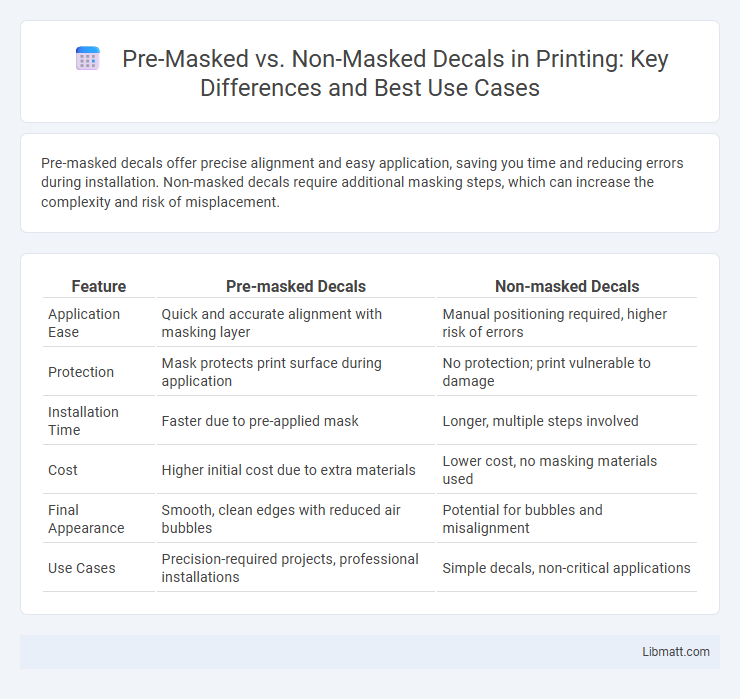

Pre-masked decals offer precise alignment and easy application, saving you time and reducing errors during installation. Non-masked decals require additional masking steps, which can increase the complexity and risk of misplacement.

Table of Comparison

| Feature | Pre-masked Decals | Non-masked Decals |

|---|---|---|

| Application Ease | Quick and accurate alignment with masking layer | Manual positioning required, higher risk of errors |

| Protection | Mask protects print surface during application | No protection; print vulnerable to damage |

| Installation Time | Faster due to pre-applied mask | Longer, multiple steps involved |

| Cost | Higher initial cost due to extra materials | Lower cost, no masking materials used |

| Final Appearance | Smooth, clean edges with reduced air bubbles | Potential for bubbles and misalignment |

| Use Cases | Precision-required projects, professional installations | Simple decals, non-critical applications |

Introduction to Decals: Pre-masked vs Non-masked

Pre-masked decals come with a protective masking layer that preserves delicate details and simplifies application by preventing paint bleed, ensuring precise and clean finishes. Non-masked decals require extra care during application to avoid smudging or misalignment, often demanding more skill and time for optimal results. Choosing between pre-masked and non-masked decals affects your workflow and the quality of your final project, with pre-masked options ideal for intricate designs and beginners.

What Are Pre-masked Decals?

Pre-masked decals are adhesive graphics with a protective layer or tape applied over the design, allowing for easier handling and precise placement during installation. The pre-mask holds the decal intact, preventing distortion and ensuring accurate alignment on surfaces. This feature simplifies the application process, especially for complex or multi-piece designs, reducing the risk of errors and saving time.

Understanding Non-masked Decals

Non-masked decals are adhesive graphics applied directly without a protective masking layer, allowing for immediate adhesion to surfaces. These decals require precise handling and alignment during installation to avoid air bubbles and misplacement. Their design offers greater flexibility for intricate shapes but demands more skill compared to pre-masked decals typically used for easier application and positioning.

Key Differences Between Pre-masked and Non-masked Decals

Pre-masked decals feature a layer of protective tape that simplifies precise placement and reduces the risk of damage during application, while non-masked decals require careful handling and additional tools for accurate positioning. Pre-masked decals save time and effort by allowing immediate transfer without extra preparation, whereas non-masked decals involve a more intricate application process to avoid wrinkles or misalignment. The choice between pre-masked and non-masked decals depends on project complexity, desired precision, and skill level, influencing overall efficiency and finish quality.

Installation Process: Pre-masked vs Non-masked Decals

Pre-masked decals simplify the installation process by incorporating a protective transfer tape that keeps the design intact, allowing for precise alignment and easy application in a single step. Non-masked decals require careful positioning and manual handling, often necessitating additional tools like application fluid and squeegees to prevent bubbles and misalignment. The pre-masked option significantly reduces installation time and minimizes errors, making it ideal for both beginners and professional installers.

Durability and Longevity of Each Decal Type

Pre-masked decals offer enhanced durability due to their protective tape layer, which prevents damage during application and ensures sharper edges, extending the lifespan of your graphics. Non-masked decals, while often easier to apply for simple designs, are more prone to peeling and fading over time, reducing their longevity, especially in harsh weather conditions. Choosing pre-masked decals provides a more resilient option for long-term outdoor use and challenging installation environments.

Cost Comparison: Pre-masked vs Non-masked Decals

Pre-masked decals generally incur higher upfront costs due to additional materials and labor involved in applying the masking film, which simplifies installation and reduces errors. Non-masked decals are more cost-effective initially but may require more time and skill during application, potentially increasing labor expenses and leading to installation mistakes. Overall, pre-masked decals offer savings in total project cost through reduced installation time and error-related waste, despite their higher purchase price.

Application Scenarios: Selecting the Right Decal Type

Pre-masked decals are ideal for complex designs requiring precise alignment, commonly used in automotive graphics and detailed signage, ensuring clean edges and easy placement. Non-masked decals suit simpler applications such as window stickers or small promotional graphics where quick application and cost-effectiveness are priorities. Choosing between pre-masked and non-masked decals depends on the project's intricacy, surface type, and budget constraints.

Common Issues and Troubleshooting

Pre-masked decals simplify application by holding fragile parts in place, reducing misalignment and tearing commonly seen with non-masked decals. You may encounter issues like residue or difficulty removing the mask in pre-masked decals, whereas non-masked decals often risk breaking or shifting during soak and transfer. Proper soaking time and gentle handling are crucial troubleshooting steps to prevent damage and ensure accurate placement for both decal types.

Conclusion: Deciding Between Pre-masked and Non-masked Decals

Pre-masked decals offer precise alignment and protection during application, reducing installation errors, while non-masked decals require more skill but allow for easier customization. Choosing between them depends on the user's experience level, the complexity of the design, and the installation environment. For beginners or large-scale projects, pre-masked decals ensure efficiency and accuracy, whereas experienced installers may prefer non-masked decals for greater flexibility.

Pre-masked vs Non-masked Decals Infographic

libmatt.com

libmatt.com