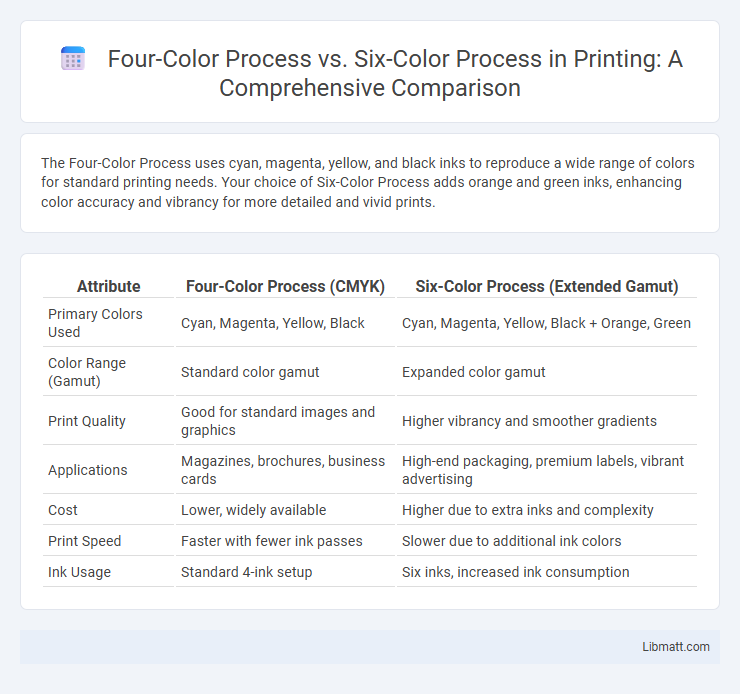

The Four-Color Process uses cyan, magenta, yellow, and black inks to reproduce a wide range of colors for standard printing needs. Your choice of Six-Color Process adds orange and green inks, enhancing color accuracy and vibrancy for more detailed and vivid prints.

Table of Comparison

| Attribute | Four-Color Process (CMYK) | Six-Color Process (Extended Gamut) |

|---|---|---|

| Primary Colors Used | Cyan, Magenta, Yellow, Black | Cyan, Magenta, Yellow, Black + Orange, Green |

| Color Range (Gamut) | Standard color gamut | Expanded color gamut |

| Print Quality | Good for standard images and graphics | Higher vibrancy and smoother gradients |

| Applications | Magazines, brochures, business cards | High-end packaging, premium labels, vibrant advertising |

| Cost | Lower, widely available | Higher due to extra inks and complexity |

| Print Speed | Faster with fewer ink passes | Slower due to additional ink colors |

| Ink Usage | Standard 4-ink setup | Six inks, increased ink consumption |

Introduction to Color Printing Processes

The Four-Color Process, also known as CMYK, uses cyan, magenta, yellow, and black inks to reproduce a wide range of colors through color layering. In contrast, the Six-Color Process incorporates additional inks, often orange and green, to expand the color gamut and produce more vibrant and accurate color prints. These color printing processes are essential in industries like packaging and advertising for achieving high-quality, precise color reproduction.

Understanding the Four-Color Process (CMYK)

The Four-Color Process, also known as CMYK, utilizes cyan, magenta, yellow, and black inks to reproduce a wide spectrum of colors in printing. This subtractive color model works by layering these four inks in varying percentages to create rich, detailed images. CMYK is the industry standard for full-color printing due to its efficiency and ability to accurately represent most colors within the printable gamut.

Exploring the Six-Color Process (CMYKOG/CMYK+2)

The Six-Color Process (CMYKOG) extends the traditional Four-Color Process (CMYK) by incorporating orange and green inks, significantly expanding the color gamut and enabling more vibrant, accurate color reproduction. This enhancement benefits industries requiring precise color matching, such as high-end packaging and fine art prints, by producing richer gradients and smoother skin tones. Advanced presses utilizing CMYK+2 reduce color shifts and improve overall print quality, making the six-color process a superior choice for complex, color-critical projects.

Key Differences Between Four-Color and Six-Color Printing

Four-color process printing uses cyan, magenta, yellow, and black (CMYK) inks to create a wide range of colors, while six-color process adds orange and green inks for an expanded color gamut and more vibrant print results. The six-color process improves color accuracy and depth, making it ideal for high-quality photo printing and complex graphics. Your choice depends on the desired color richness and print precision, with six-color offering superior color reproduction compared to four-color.

Advantages of Four-Color Process

The Four-Color Process, using Cyan, Magenta, Yellow, and Black (CMYK) inks, offers efficient and cost-effective color reproduction for most printing needs. This process ensures faster turnaround times and compatibility with a wide range of printing materials and equipment, making it ideal for standard marketing materials. For Your projects requiring vibrant, full-color images without specialized color demands, the Four-Color Process delivers excellent results with optimized resource use.

Advantages of Six-Color Process

The Six-Color Process enhances print quality by expanding the color gamut beyond the standard CMYK, resulting in more vibrant and accurate color reproduction. This process includes additional inks such as orange and green, which improve color saturation and reduce graininess, making images appear sharper and more detailed. Your designs benefit from greater visual impact and smoother gradients, ideal for high-end photography and intricate graphics.

Color Quality and Print Resolution Comparison

The Four-Color Process (CMYK) uses cyan, magenta, yellow, and black inks to achieve a broad color spectrum but can struggle with reproducing certain shades and subtle gradients, often resulting in less vibrant prints. The Six-Color Process adds orange and green inks, expanding the printable color gamut and enhancing color accuracy, especially for bright and saturated hues. Regarding print resolution, both processes typically operate at comparable DPI settings, but the additional inks in the Six-Color Process contribute to smoother tonal transitions and richer image detail.

Applications and Use Cases for Each Process

The Four-Color Process (CMYK) is predominantly used in standard commercial printing applications such as magazines, brochures, and packaging where cost-efficiency and color accuracy for photographic images are essential. The Six-Color Process expands the CMYK model by incorporating additional inks like orange and green or light cyan and light magenta, enhancing color gamut and vibrancy, making it ideal for high-end printing projects like premium packaging, fine art reproductions, and brand materials requiring precise color matching. Industries such as advertising and product design leverage the Six-Color Process to achieve superior color depth and visual impact that standard CMYK cannot deliver.

Cost Implications and Production Considerations

The Four-Color Process (CMYK) typically offers lower production costs due to fewer inks and simpler press setups, making it ideal for standard color printing needs with budget constraints. In contrast, the Six-Color Process incorporates additional inks, such as light cyan and light magenta, enhancing color accuracy and vibrancy but increasing both material and setup expenses. Your choice between these methods should balance color fidelity requirements against cost efficiency and printing complexity.

Choosing the Right Color Process for Your Print Project

Selecting the appropriate color process hinges on the complexity and color accuracy required for your print project. The Four-Color Process (CMYK) efficiently reproduces a broad spectrum of colors for most standard print jobs, making it cost-effective for general promotional materials. For projects demanding enhanced color vibrancy and a wider color gamut, such as high-end photography or brand-specific color matching, the Six-Color Process--typically CMYK plus Orange and Green inks--offers superior precision and depth.

Four-Color Process vs Six-Color Process Infographic

libmatt.com

libmatt.com