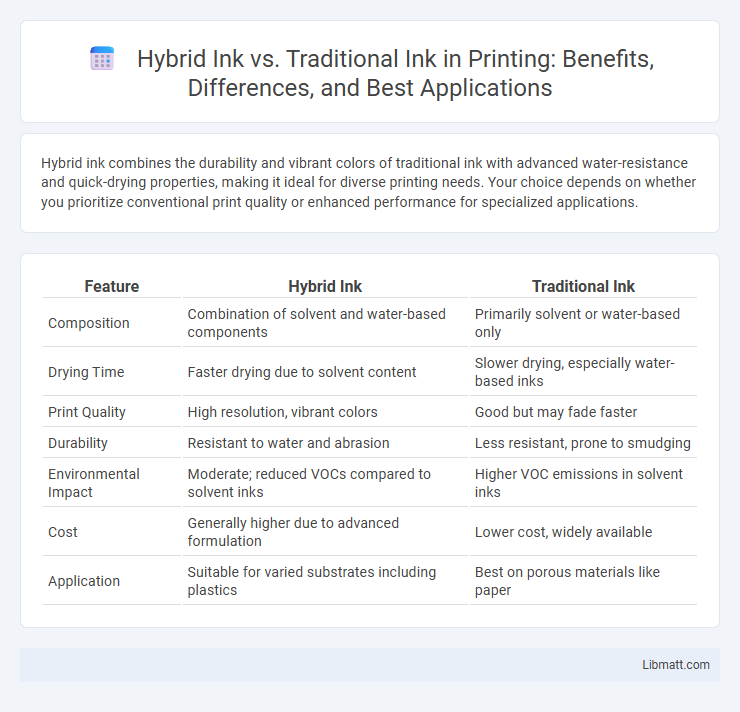

Hybrid ink combines the durability and vibrant colors of traditional ink with advanced water-resistance and quick-drying properties, making it ideal for diverse printing needs. Your choice depends on whether you prioritize conventional print quality or enhanced performance for specialized applications.

Table of Comparison

| Feature | Hybrid Ink | Traditional Ink |

|---|---|---|

| Composition | Combination of solvent and water-based components | Primarily solvent or water-based only |

| Drying Time | Faster drying due to solvent content | Slower drying, especially water-based inks |

| Print Quality | High resolution, vibrant colors | Good but may fade faster |

| Durability | Resistant to water and abrasion | Less resistant, prone to smudging |

| Environmental Impact | Moderate; reduced VOCs compared to solvent inks | Higher VOC emissions in solvent inks |

| Cost | Generally higher due to advanced formulation | Lower cost, widely available |

| Application | Suitable for varied substrates including plastics | Best on porous materials like paper |

Introduction to Hybrid and Traditional Inks

Hybrid ink combines the advantages of water-based and solvent-based inks, offering vibrant colors with enhanced durability and faster drying times. Traditional inks, primarily solvent-based, have long been favored for their strong adhesion and resistance but often emit higher levels of volatile organic compounds (VOCs). The evolution from traditional to hybrid inks addresses environmental concerns while maintaining performance in various printing applications.

Composition Differences: Hybrid vs Traditional Inks

Hybrid inks combine water-based and solvent-based components, offering improved adhesion and faster drying times compared to traditional inks, which rely solely on either water or solvent bases. The composition of hybrid inks typically includes a balanced mix of resins, pigments, and additives designed to enhance durability, flexibility, and environmental resistance. Traditional inks, by contrast, often exhibit limited versatility and longer curing processes due to their singular base composition, impacting their performance on diverse substrates.

Performance and Writing Experience

Hybrid ink combines the smooth flow and quick-drying properties of gel ink with the vibrant color intensity and durability of traditional dye-based ink, resulting in enhanced writing performance. This innovative formula provides consistent ink distribution, reducing smudging and skipping, which improves overall writing comfort and precision. Users experience a balance of vivid colors and smooth application that outperforms many conventional inks in both daily writing and creative tasks.

Drying Time and Smudge Resistance

Hybrid ink dries significantly faster than traditional ink due to its advanced formulation combining water-based and solvent-based components, reducing wait times in printing processes. Its enhanced smudge resistance prevents ink transfer, maintaining print clarity and durability on various paper types. Traditional inks often require longer drying periods and are more prone to smudging, especially on glossy or coated surfaces.

Color Vibrancy and Longevity

Hybrid ink offers superior color vibrancy compared to traditional ink, delivering richer and more vivid hues that enhance print quality. Its composition ensures longer longevity, resisting fading and maintaining color integrity over extended periods, making it ideal for archival or outdoor uses. Choosing hybrid ink can elevate your prints with both striking visuals and durable performance.

Compatibility with Paper Types

Hybrid ink offers superior compatibility with a wider range of paper types compared to traditional ink, including glossy, matte, and textured surfaces. This versatility ensures sharper prints and faster drying times on diverse media, reducing smudging and bleeding risks. Your printing projects benefit from enhanced color vibrancy and durability, regardless of the paper choice.

Environmental Impact and Sustainability

Hybrid ink significantly reduces environmental impact due to its lower volatile organic compound (VOC) emissions and biodegradable components compared to traditional solvent-based inks. Traditional inks often contain heavy metals and non-renewable petroleum derivatives, leading to higher toxicity and longer degradation times in waste streams, whereas hybrid inks utilize bio-based solvents and waterborne formulas that enhance recyclability and reduce carbon footprint. The adoption of hybrid ink technology supports sustainable printing practices by minimizing hazardous waste and conserving natural resources, aligning with global environmental regulations and eco-friendly production goals.

Cost Comparison and Value

Hybrid ink offers a cost-effective alternative to traditional ink by reducing the need for frequent replacements due to its higher durability and efficiency. Traditional ink generally incurs higher long-term expenses because of its lower pigment concentration and quicker drying times, which lead to more frequent cartridge changes and higher waste. The enhanced performance of hybrid ink delivers superior value for businesses seeking to minimize printing costs while maintaining print quality.

Popular Applications and Use Cases

Hybrid ink combines the durability and vibrant colors of traditional ink with the fast-drying properties of digital ink, making it ideal for high-quality packaging, labels, and promotional materials. Traditional ink remains popular for newspapers, books, and large-scale print runs where cost efficiency and long-established printing processes are prioritized. Your choice between hybrid ink and traditional ink depends on the specific requirements of your project's application, balancing factors like print speed, color vibrancy, and substrate compatibility.

Choosing the Right Ink for Your Needs

Hybrid ink combines the vibrant colors and quick-drying properties of traditional ink with enhanced durability and water resistance, making it ideal for projects requiring long-lasting prints. Traditional ink offers a classic finish with proven performance, often favored for its cost-effectiveness and compatibility with various printing surfaces. Assessing your specific printing requirements, such as exposure to moisture or the desired longevity, will help you determine if hybrid ink or traditional ink best suits your needs.

Hybrid ink vs traditional ink Infographic

libmatt.com

libmatt.com