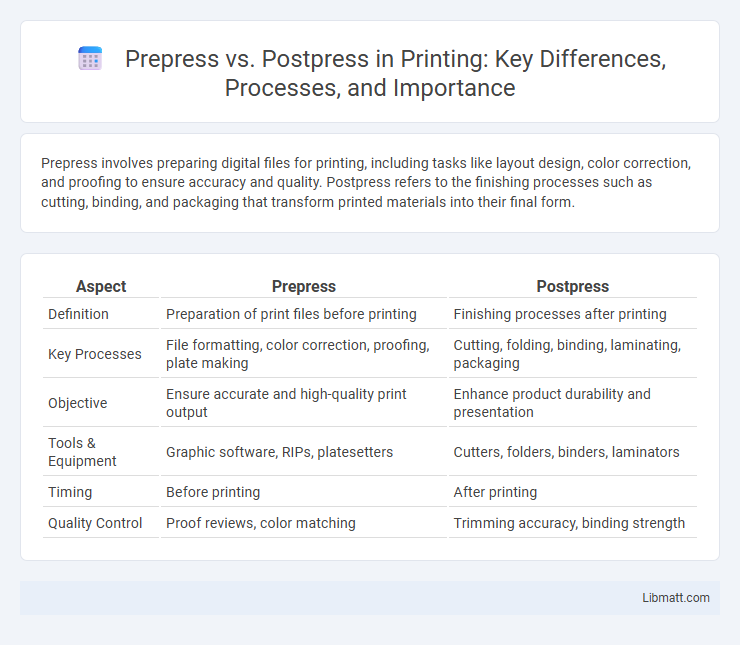

Prepress involves preparing digital files for printing, including tasks like layout design, color correction, and proofing to ensure accuracy and quality. Postpress refers to the finishing processes such as cutting, binding, and packaging that transform printed materials into their final form.

Table of Comparison

| Aspect | Prepress | Postpress |

|---|---|---|

| Definition | Preparation of print files before printing | Finishing processes after printing |

| Key Processes | File formatting, color correction, proofing, plate making | Cutting, folding, binding, laminating, packaging |

| Objective | Ensure accurate and high-quality print output | Enhance product durability and presentation |

| Tools & Equipment | Graphic software, RIPs, platesetters | Cutters, folders, binders, laminators |

| Timing | Before printing | After printing |

| Quality Control | Proof reviews, color matching | Trimming accuracy, binding strength |

Understanding Prepress and Postpress

Prepress involves all the preparations before printing, including designing, typesetting, and creating printing plates to ensure accuracy and quality. Postpress refers to processes after printing, such as cutting, folding, binding, and finishing, which enhance the final product's appearance and durability. Understanding the distinct functions of prepress and postpress helps you optimize workflow and achieve superior print results.

Key Differences Between Prepress and Postpress

Prepress involves all the preparation steps before printing, such as designing, typesetting, color correction, and plate-making, ensuring files are print-ready. Postpress covers finishing processes after printing, including cutting, folding, binding, laminating, and packaging, which finalize the product for distribution. Understanding these key differences helps optimize your workflow by aligning prepress accuracy with effective postpress finishing techniques.

Main Processes in Prepress

Main processes in prepress include image editing, color correction, and layout design, which prepare digital files for printing. File proofing ensures accuracy and consistency before production begins, minimizing errors and material waste. Your careful attention during prepress optimizes print quality and streamlines the entire print workflow.

Essential Steps in Postpress

Essential steps in postpress include cutting, folding, binding, and finishing processes that transform printed materials into final products. Techniques like trimming, scoring, laminating, and embossing enhance durability and aesthetics, ensuring your printed pieces meet quality standards. Accurate postpress operations are crucial for achieving professional results after the initial prepress and printing stages.

Prepress Technologies and Tools

Prepress technologies and tools encompass digital imaging, color management software, and platemaking systems that prepare designs for high-quality printing. These tools ensure accurate file formatting, image resolution, and color calibration before the printing process begins, minimizing errors and production delays. Investing in advanced prepress solutions enhances Your print workflow efficiency and final product consistency.

Postpress Equipment and Techniques

Postpress equipment includes cutting machines, folding machines, laminators, and binding systems such as saddle stitchers and perfect binders, all designed to enhance the final product's appearance and durability. Techniques like embossing, die-cutting, and UV coating add texture and visual appeal, making your printed materials stand out. Efficient use of postpress technology streamlines the finishing phase, ensuring high-quality results and faster turnaround times.

Quality Control in Prepress vs Postpress

Quality control in prepress ensures the accuracy of digital files, color consistency, and proper layout before printing begins, preventing costly errors and material wastage. Postpress quality control focuses on the inspection of finished products, including trimming, binding, and packaging, to guarantee the final output meets design specifications and customer expectations. Your project's overall success depends on rigorous quality checks in both prepress and postpress phases to maintain high standards throughout the printing process.

Common Challenges in Prepress and Postpress

Common challenges in prepress include color management inconsistencies, file format errors, and incorrect image resolution that can compromise print quality. In postpress, issues such as misalignment during binding, glazing defects, and delays in finishing processes often affect the final product. Addressing these challenges requires precise quality control, advanced software tools, and skilled technicians to ensure seamless transitions between prepress and postpress stages.

Impact of Prepress and Postpress on Print Quality

Prepress significantly influences print quality by ensuring accurate color calibration, image resolution, and layout alignment before printing begins. Postpress enhances the final product through precise cutting, binding, folding, and finishing techniques that add professionalism and durability. Your print output's clarity and appeal depend heavily on both prepress preparation and meticulous postpress execution.

Future Trends in Prepress and Postpress

Future trends in prepress include increased automation through AI-driven file preparation and enhanced color accuracy using advanced spectral imaging. Postpress advancements focus on sustainable binding techniques and intelligent finishing processes powered by robotics, improving efficiency and customization. Integration of digital workflows from prepress to postpress promises streamlined production and reduced turnaround times in printing.

Prepress vs postpress Infographic

libmatt.com

libmatt.com