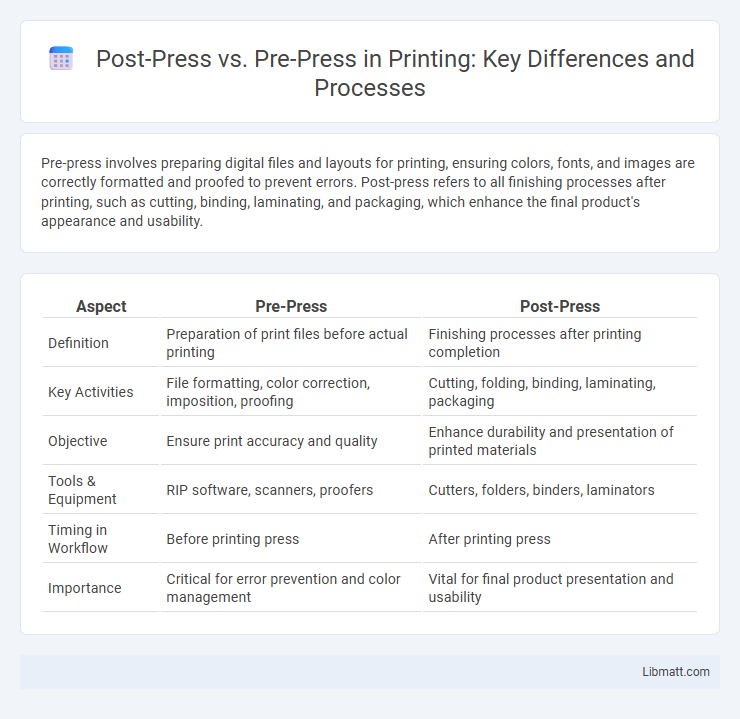

Pre-press involves preparing digital files and layouts for printing, ensuring colors, fonts, and images are correctly formatted and proofed to prevent errors. Post-press refers to all finishing processes after printing, such as cutting, binding, laminating, and packaging, which enhance the final product's appearance and usability.

Table of Comparison

| Aspect | Pre-Press | Post-Press |

|---|---|---|

| Definition | Preparation of print files before actual printing | Finishing processes after printing completion |

| Key Activities | File formatting, color correction, imposition, proofing | Cutting, folding, binding, laminating, packaging |

| Objective | Ensure print accuracy and quality | Enhance durability and presentation of printed materials |

| Tools & Equipment | RIP software, scanners, proofers | Cutters, folders, binders, laminators |

| Timing in Workflow | Before printing press | After printing press |

| Importance | Critical for error prevention and color management | Vital for final product presentation and usability |

Introduction to Pre-Press and Post-Press

Pre-press involves all preparatory steps like design layout, color correction, and plate making to ensure print readiness. Post-press encompasses finishing processes such as cutting, binding, and laminating to enhance the final product's appearance and durability. Understanding these stages helps you optimize workflow and achieve high-quality printed materials.

Defining Pre-Press Processes

Pre-press processes encompass the essential steps required to prepare digital files for printing, including file formatting, color correction, imposition, trapping, and proofing to ensure accuracy and print quality. These processes are critical for identifying and fixing errors prior to production, streamlining workflow, and reducing waste. Pre-press combines software tools like Adobe InDesign, Photoshop, and specialized RIP software to optimize images and layouts for efficient printing.

Key Steps in Post-Press Operations

Post-press operations involve crucial steps such as cutting, folding, binding, and laminating that enhance the final appearance and durability of printed materials. These processes ensure that your printed products meet precise specifications, improve handling, and prepare items for distribution or sale. Quality control during post-press is essential to guarantee that each piece maintains consistency and professional finish.

Technology Used in Pre-Press

Pre-press technology involves advanced software such as Adobe Photoshop, Illustrator, and InDesign for layout design and image editing, alongside RIP (Raster Image Processor) systems that convert images into printable formats. Digital proofing tools and color management systems ensure accurate color reproduction before printing, enhancing print quality and reducing errors. Your workflow benefits from these technologies by streamlining file preparation and improving final product consistency.

Post-Press Machinery and Tools

Post-press machinery and tools include cutting machines, binding equipment, laminators, and embossers designed to finalize printed materials with precision and durability. These tools enhance the quality and functionality of print products by enabling tasks such as trimming, folding, stapling, and coating, which are essential after the printing process. Your choice of post-press equipment directly impacts the efficiency and professional finish of the final output.

Impact of Pre-Press on Print Quality

Pre-press significantly influences print quality by ensuring accurate color management, image resolution, and layout precision before printing begins. Proper file preparation and proofing during pre-press minimize errors, reducing waste and enhancing the final output's sharpness and color consistency. Your attention to detail in pre-press stages directly determines the clarity and professionalism of printed materials.

Enhancing Products with Post-Press Techniques

Post-press techniques enhance printed products by applying finishing touches such as embossing, foil stamping, and lamination, which increase durability and visual appeal. These processes complement pre-press preparations by transforming standard prints into premium, tactile experiences that capture attention and elevate brand perception. Ensuring your designs incorporate post-press options can significantly boost the overall quality and impact of your printed materials.

Common Challenges in Pre-Press and Post-Press

Common challenges in pre-press include color calibration inconsistencies, file format errors, and improper resolution settings that can lead to poor print quality. Post-press issues often involve misalignment during cutting, binding defects, and variable finishing quality, affecting the final product's durability and appearance. Ensuring your workflow addresses these challenges helps maintain precision from design through final production.

Cost Factors: Pre-Press vs Post-Press

Pre-press costs typically include software, design, proofing, and preparing files, which require skilled technicians and specialized equipment, making it a significant upfront investment. Post-press expenses involve finishing operations like cutting, binding, laminating, and packaging, often driven by labor intensity and the complexity of the final product. Understanding these cost factors helps you allocate your budget effectively between preparation and finishing stages for optimal print production efficiency.

Future Trends in Print Production Processes

Future trends in print production processes highlight increasing integration of automation and AI technology in both post-press and pre-press stages, enhancing efficiency and accuracy. Pre-press workflows are evolving with advanced digital proofing and variable data printing, while post-press benefits from robotic assembly and smart sorting systems. Your print operations will gain from adopting these innovations, ensuring faster turnaround times and reduced errors.

post-press vs pre-press Infographic

libmatt.com

libmatt.com