Split fountain systems provide enhanced cooling by separating the water fountain components from the refrigeration unit, allowing quieter operation and easier maintenance. Split duct systems, on the other hand, separate the air handler from the condensing unit, optimizing airflow control and increasing energy efficiency in HVAC installations.

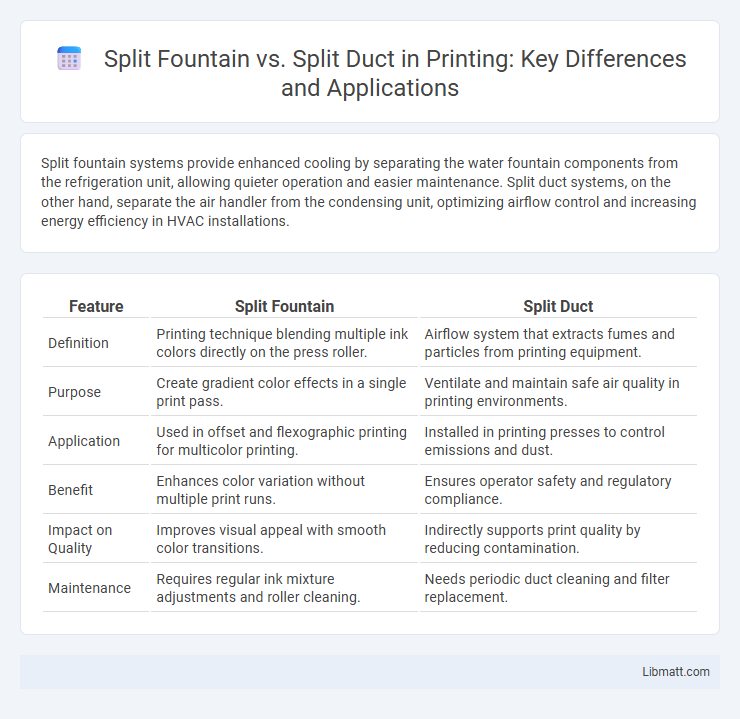

Table of Comparison

| Feature | Split Fountain | Split Duct |

|---|---|---|

| Definition | Printing technique blending multiple ink colors directly on the press roller. | Airflow system that extracts fumes and particles from printing equipment. |

| Purpose | Create gradient color effects in a single print pass. | Ventilate and maintain safe air quality in printing environments. |

| Application | Used in offset and flexographic printing for multicolor printing. | Installed in printing presses to control emissions and dust. |

| Benefit | Enhances color variation without multiple print runs. | Ensures operator safety and regulatory compliance. |

| Impact on Quality | Improves visual appeal with smooth color transitions. | Indirectly supports print quality by reducing contamination. |

| Maintenance | Requires regular ink mixture adjustments and roller cleaning. | Needs periodic duct cleaning and filter replacement. |

Understanding Split Fountain and Split Duct Techniques

Split fountain technique involves using multiple ink colors separated within a single printing plate to create gradient or blended color effects without changing plates, enhancing print efficiency and visual appeal. Split duct technique refers to dividing ink delivery ducts in printing machines to control and distribute different ink colors precisely, enabling better color registration and consistency in multi-color printing processes. Both techniques improve color management in printing by optimizing ink application for complex designs and high-quality outputs.

Definition and Core Principles of Split Fountain

Split fountain is a printing technique that blends two or more ink colors on a single plate, creating a gradient effect during the press run. Split duct, by contrast, refers to an HVAC system design where air ducts branch off into separate paths to regulate airflow in different zones. While split fountain emphasizes color transition through ink distribution on a press, split duct focuses on airflow management in ventilation systems.

What is Split Duct in Printing?

Split duct in printing refers to a technique where two or more colors are channeled through separate compartments within a single ink duct, allowing precise control of ink flow and color blending on the press. This method enhances color consistency and expands creative possibilities by enabling smooth gradients and multi-hue effects without additional plates. Your print production benefits from split duct technology by achieving vibrant, accurate color transitions efficiently and cost-effectively.

Key Differences Between Split Fountain and Split Duct

Split fountain systems distribute air through open, unsealed ducts allowing significant air leakage and reduced energy efficiency. Split duct configurations utilize sealed, insulated ducts that ensure controlled airflow, minimizing energy loss and improving indoor air quality. The primary difference lies in the duct sealing and airflow control, impacting system efficiency, performance, and comfort levels.

Color Blending Capabilities: Split Fountain vs Split Duct

Split fountain printing excels in smooth color blending by gradually transitioning inks across a single roller, enabling seamless gradients and subtle hues. Split duct systems, on the other hand, deliver more precise color separation with lined divisions, which limits gradient effects but enhances defined, sharp color transitions. For projects prioritizing intricate color blending and softer shifts, split fountain offers superior capabilities compared to the segmented nature of split duct printing.

Equipment and Setup Requirements

Split fountain systems require a compact, modular setup featuring individual printheads connected to a central ink delivery unit, demanding precise alignment and maintenance of the ink flow for optimal performance. Split duct systems utilize separate air handling units linked by ductwork, necessitating careful design of airflow pathways and more extensive installation space to accommodate the ducting infrastructure. Equipment complexity in split fountain setups centers around fluid dynamics and printhead calibration, whereas split duct setups focus on air distribution efficiency and duct sealing integrity.

Suitable Print Applications for Each Method

Split fountain printing is ideal for producing vibrant, multicolor gradients and complex color blends, making it suitable for packaging, posters, and promotional materials that require eye-catching visual effects. Split duct printing excels in precise two-tone or limited color applications, often used for branding, labels, and product markings where sharp, consistent color separation is essential. Choosing the right technique depends on your print project's color complexity and design requirements to optimize visual impact and production efficiency.

Cost Implications and Efficiency

Split fountain systems typically involve higher initial installation costs due to complex piping and equipment requirements but offer improved cooling efficiency by directly targeting specific zones. Split duct systems present lower upfront expenses with simpler ductwork but may result in uneven air distribution, reducing overall energy efficiency. Evaluating long-term operational costs reveals split fountain systems often achieve better energy savings despite higher initial investments.

Pros and Cons: Split Fountain vs Split Duct

Split fountain systems offer the advantage of vibrant color transitions and gradation in printing, enhancing visual appeal for Your marketing materials, but they require precise setup and can lead to color inconsistencies if not carefully managed. Split duct systems provide efficient airflow management and temperature control in HVAC applications, promoting energy savings and comfort, yet they involve higher installation costs and complexity compared to simpler duct setups. Choosing between split fountain and split duct depends on whether Your priority is superior graphic output or optimized air distribution, weighing the trade-offs of maintenance and operational precision.

Choosing the Right Technique for Your Print Project

Selecting between split fountain and split duct techniques depends on the desired color blending and precision in your print project. Split fountain offers smooth gradient transitions by blending multiple ink colors on a single roller, ideal for vibrant, artistic effects. Split duct separates inks in distinct ducts, providing sharper, more controlled color transitions suitable for detailed graphic work requiring accurate color placement.

split fountain vs split duct Infographic

libmatt.com

libmatt.com