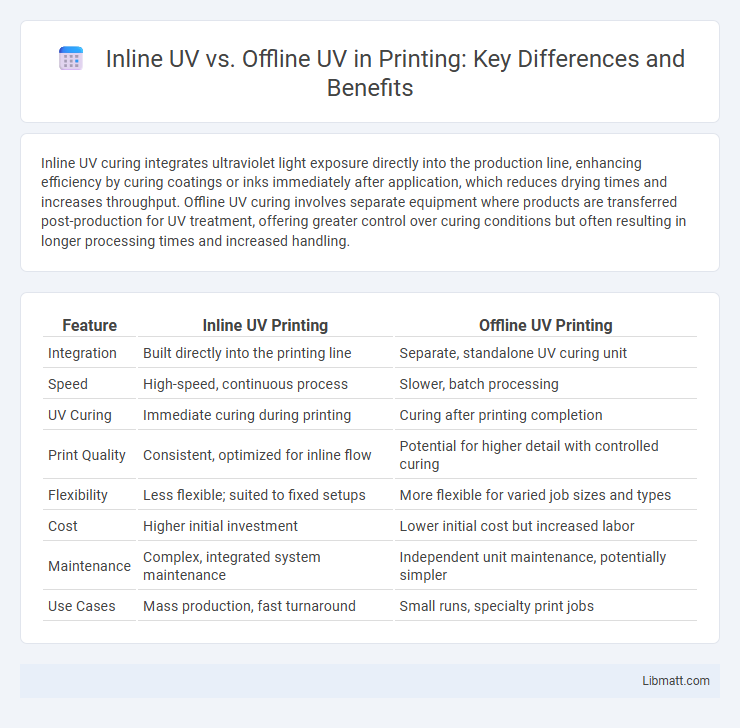

Inline UV curing integrates ultraviolet light exposure directly into the production line, enhancing efficiency by curing coatings or inks immediately after application, which reduces drying times and increases throughput. Offline UV curing involves separate equipment where products are transferred post-production for UV treatment, offering greater control over curing conditions but often resulting in longer processing times and increased handling.

Table of Comparison

| Feature | Inline UV Printing | Offline UV Printing |

|---|---|---|

| Integration | Built directly into the printing line | Separate, standalone UV curing unit |

| Speed | High-speed, continuous process | Slower, batch processing |

| UV Curing | Immediate curing during printing | Curing after printing completion |

| Print Quality | Consistent, optimized for inline flow | Potential for higher detail with controlled curing |

| Flexibility | Less flexible; suited to fixed setups | More flexible for varied job sizes and types |

| Cost | Higher initial investment | Lower initial cost but increased labor |

| Maintenance | Complex, integrated system maintenance | Independent unit maintenance, potentially simpler |

| Use Cases | Mass production, fast turnaround | Small runs, specialty print jobs |

Introduction to UV Coating Technologies

Inline UV coating systems integrate directly into the printing press, offering rapid curing and high-speed production suitable for large print runs. Offline UV coating involves applying coatings separately after printing, providing greater flexibility for specialty finishes and precise control over coating thickness. Both technologies utilize ultraviolet light to quickly harden coatings, enhancing durability, gloss, and resistance in printed materials.

Understanding Inline UV: Definition and Process

Inline UV refers to the ultraviolet curing process integrated directly into the production line, allowing coatings or inks to cure instantly as products move through the system. This method uses UV lamps positioned within the manufacturing equipment to emit specific wavelengths of ultraviolet light, triggering photochemical reactions that harden the applied materials without stopping production. The continuous curing process of inline UV enhances efficiency by reducing drying times, improving adhesion, and maintaining high-speed manufacturing workflows.

What is Offline UV Coating?

Offline UV coating is a finishing process applied separately from the printing operation, involving the use of ultraviolet light to cure a liquid coating on printed materials. This method offers higher flexibility for specialized finishes, such as spot coatings or heavier layers, which enhances durability and visual appeal. Your choice between offline UV and inline UV coating depends on production speed, finish requirements, and the complexity of the job.

Key Differences Between Inline and Offline UV

Inline UV curing integrates the ultraviolet process directly into the production line, enabling faster curing times and continuous workflow, while offline UV curing occurs separately, requiring additional handling time. Inline UV systems offer higher efficiency with real-time processing, reducing labor costs and minimizing production bottlenecks. Your choice depends on factors like production speed, space constraints, and required curing precision.

Advantages of Inline UV Coating

Inline UV coating offers significant advantages by integrating the coating process directly into the printing line, resulting in faster production times and reduced handling errors. This method ensures consistent, high-quality finishes with instant curing, improving durability and resistance to scratches and moisture. Your workflow benefits from cost-efficiency and enhanced productivity due to fewer interruptions and streamlined operations.

Benefits of Offline UV Application

Offline UV application offers superior curing control by allowing precise exposure times and intensities, resulting in consistent, high-quality finishes across diverse substrates. It enhances flexibility in production, as materials can be processed without integration constraints, enabling faster adjustments and maintenance without halting the entire workflow. This method also reduces heat-sensitive material degradation, preserving substrate integrity and extending product lifespan.

Production Efficiency: Inline UV vs Offline UV

Inline UV curing integrates the UV process directly into the production line, significantly enhancing production efficiency by reducing handling time and minimizing delays between printing and curing stages. Offline UV curing requires separate equipment and additional labor to move products between production steps, leading to longer cycle times and increased risk of defects due to handling errors. The streamlined workflow of inline UV curing supports higher throughput, consistent quality, and reduced operational costs compared to offline UV processes.

Cost Considerations for UV Coating Methods

Inline UV coating offers cost efficiency by integrating the curing process directly into the production line, reducing labor and equipment expenses. Offline UV coating involves separate curing stations, which can increase operational costs due to additional handling and longer production times. Your choice between inline and offline UV methods should balance budget constraints with desired production speed and coating precision.

Quality and Consistency in UV Finishing

Inline UV finishing offers superior quality and consistency by integrating the UV curing process directly into the production line, ensuring precise control over drying times and uniform coating application. Offline UV finishing can result in variability due to separate handling and potential exposure to contaminants before curing, leading to uneven textures or inconsistent gloss levels. You can achieve faster turnaround times and reduced defects with inline UV, making it ideal for high-volume, quality-sensitive production runs.

Choosing the Right UV Coating Method for Your Needs

Inline UV coating integrates seamlessly into your existing production line, offering faster drying times and higher throughput for projects requiring quick turnaround. Offline UV coating provides greater flexibility and superior finish quality, ideal for specialized or lower-volume tasks where precision is paramount. Evaluating your production speed, budget, and desired finish will help you choose the optimal UV coating method for your needs.

Inline UV vs offline UV Infographic

libmatt.com

libmatt.com