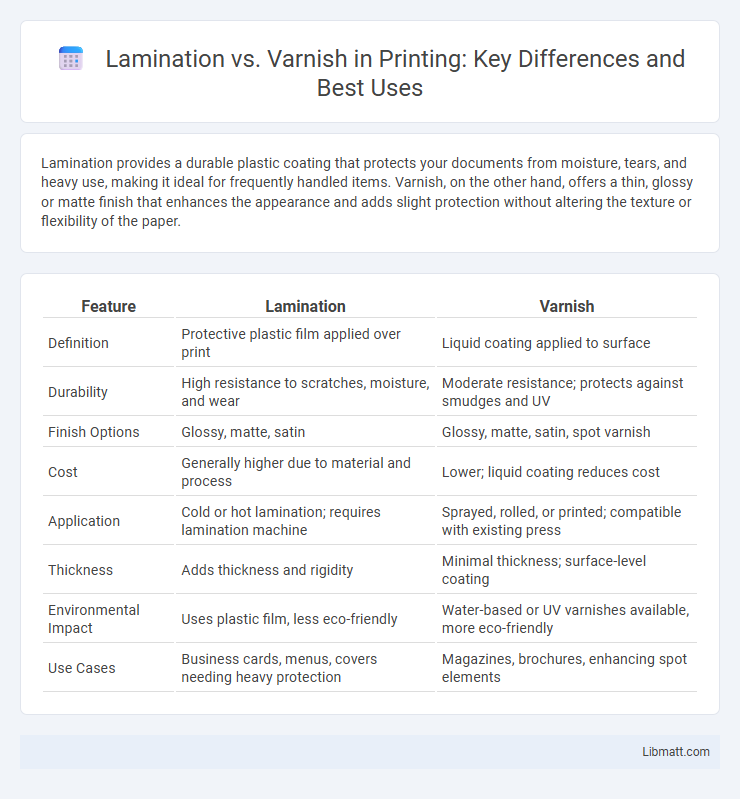

Lamination provides a durable plastic coating that protects your documents from moisture, tears, and heavy use, making it ideal for frequently handled items. Varnish, on the other hand, offers a thin, glossy or matte finish that enhances the appearance and adds slight protection without altering the texture or flexibility of the paper.

Table of Comparison

| Feature | Lamination | Varnish |

|---|---|---|

| Definition | Protective plastic film applied over print | Liquid coating applied to surface |

| Durability | High resistance to scratches, moisture, and wear | Moderate resistance; protects against smudges and UV |

| Finish Options | Glossy, matte, satin | Glossy, matte, satin, spot varnish |

| Cost | Generally higher due to material and process | Lower; liquid coating reduces cost |

| Application | Cold or hot lamination; requires lamination machine | Sprayed, rolled, or printed; compatible with existing press |

| Thickness | Adds thickness and rigidity | Minimal thickness; surface-level coating |

| Environmental Impact | Uses plastic film, less eco-friendly | Water-based or UV varnishes available, more eco-friendly |

| Use Cases | Business cards, menus, covers needing heavy protection | Magazines, brochures, enhancing spot elements |

Introduction to Lamination and Varnish

Lamination involves applying a thin plastic film to printed materials to enhance durability, water resistance, and appearance, commonly used for menus, business cards, and book covers. Varnish is a clear liquid coating applied to paper or cardstock to provide a protective layer that can be matte, gloss, or satin, improving print longevity and visual texture. Both techniques serve to protect and augment printed surfaces but differ in material form and specific finish effects.

Defining Lamination: Process and Purpose

Lamination involves applying a thin protective layer of plastic film over printed materials to enhance durability, water resistance, and UV protection. This process uses heat and pressure to bond the film to surfaces like paper or cardboard, increasing rigidity and lifespan. Your printed products benefit from lamination by gaining a professional finish that safeguards against scratches, moisture, and fading.

What Is Varnish? A Quick Overview

Varnish is a transparent protective coating applied to printed materials, enhancing durability and providing resistance against moisture, scratches, and UV light. Unlike lamination, which involves bonding a plastic film to the surface, varnish forms a thin, glossy or matte layer that maintains the natural texture of the paper. Commonly used in business cards, brochures, and book covers, varnish allows for detailed print visibility while offering moderate protection.

Key Differences Between Lamination and Varnish

Lamination involves applying a thin plastic film over printed materials, providing enhanced durability, water resistance, and a glossy or matte finish, while varnish is a liquid coating applied to the surface to add shine or texture without significant protection. Laminated surfaces are more resistant to scratches and wear, making them ideal for frequent handling, whereas varnish offers aesthetic enhancement and can highlight specific areas through spot varnishing. Understanding these key differences helps you choose the best finish for your project's durability and visual appeal needs.

Advantages of Lamination for Printed Materials

Lamination provides superior protection for printed materials by creating a durable, moisture-resistant barrier that prevents damage from spills, tears, and fading. This process enhances color vibrancy and clarity, ensuring your materials maintain a professional appearance over time. Unlike varnish, lamination offers increased longevity and a premium feel, making it ideal for frequently handled documents or marketing collateral.

Benefits of Using Varnish in Printing

Using varnish in printing enhances the visual appeal by adding a glossy, matte, or satin finish that accentuates colors and contrasts, making designs more vibrant and eye-catching. Varnish also provides a protective layer that resists scratches, fingerprints, and moisture, extending the durability of printed materials without the thickness or rigidity associated with lamination. This treatment is cost-effective for short print runs and flexible formats, allowing for selective application such as spot varnish to highlight specific design elements.

Cost Comparison: Lamination vs Varnish

Lamination generally incurs higher upfront costs due to materials and equipment needed, whereas varnish offers a more budget-friendly option with lower application expenses. Laminated surfaces provide superior durability and protection, potentially reducing long-term replacement costs compared to varnish-coated items that may require frequent touch-ups. Choosing between lamination and varnish depends on balancing initial investment against the desired lifespan and resilience of the finished product.

Durability and Protection: Which Lasts Longer?

Lamination offers superior durability and protection compared to varnish due to its thicker plastic coating that resists moisture, scratches, and fading more effectively. While varnish provides a glossy finish that enhances appearance, it is more prone to chipping and wear over time, especially in high-contact environments. For long-lasting protection, lamination is the preferred choice in preserving printed materials and extending their lifespan.

Environmental Impact: Sustainability Considerations

Lamination often uses plastic films derived from non-renewable resources, raising concerns about long-term environmental impact due to limited biodegradability. Varnish, particularly water-based or UV-cured options, offers a more sustainable alternative with lower volatile organic compound (VOC) emissions and easier recyclability. Choosing eco-friendly varnishes supports sustainable packaging by reducing carbon footprints and minimizing waste in the printing industry.

Choosing the Right Finish for Your Project

Lamination provides a durable, protective layer that enhances resistance to water, scratches, and wear, making it ideal for high-traffic or frequently handled materials. Varnish offers a glossy or matte finish that enhances visual appeal while providing moderate protection, best suited for projects where appearance is a priority but heavy durability is less critical. Choosing the right finish for your project depends on balancing the need for durability with aesthetic preferences to ensure the final product meets your functional and visual requirements.

Lamination vs varnish Infographic

libmatt.com

libmatt.com