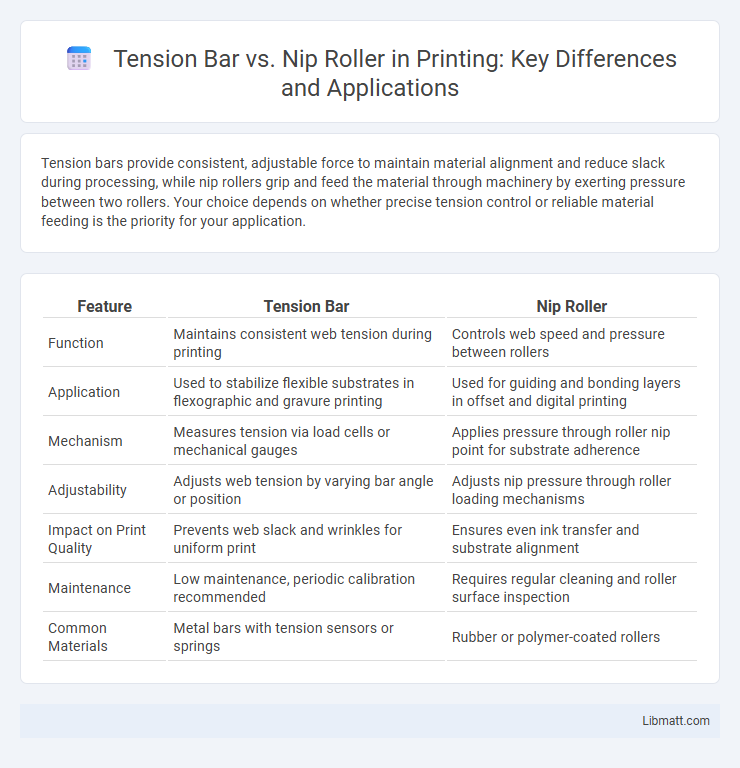

Tension bars provide consistent, adjustable force to maintain material alignment and reduce slack during processing, while nip rollers grip and feed the material through machinery by exerting pressure between two rollers. Your choice depends on whether precise tension control or reliable material feeding is the priority for your application.

Table of Comparison

| Feature | Tension Bar | Nip Roller |

|---|---|---|

| Function | Maintains consistent web tension during printing | Controls web speed and pressure between rollers |

| Application | Used to stabilize flexible substrates in flexographic and gravure printing | Used for guiding and bonding layers in offset and digital printing |

| Mechanism | Measures tension via load cells or mechanical gauges | Applies pressure through roller nip point for substrate adherence |

| Adjustability | Adjusts web tension by varying bar angle or position | Adjusts nip pressure through roller loading mechanisms |

| Impact on Print Quality | Prevents web slack and wrinkles for uniform print | Ensures even ink transfer and substrate alignment |

| Maintenance | Low maintenance, periodic calibration recommended | Requires regular cleaning and roller surface inspection |

| Common Materials | Metal bars with tension sensors or springs | Rubber or polymer-coated rollers |

Introduction to Tension Bars and Nip Rollers

Tension bars and nip rollers are essential components in web handling and material processing systems, designed to control the tension and movement of flexible materials like films, papers, and textiles. A tension bar regulates web tension by applying a consistent force, preventing slack or breakage, while nip rollers use pressure created between two rolls to grip and drive the material smoothly through the system. Understanding the differences in their operation can help you optimize material handling efficiency and maintain product quality in your production line.

Key Functions of Tension Bars

Tension bars maintain consistent tension in materials during printing or converting processes, preventing wrinkles and ensuring smooth, even feeding through machines. By applying precise pressure, tension bars stabilize the web, minimizing slack and stretching, which is crucial for high-quality print results. Your production efficiency improves as tension bars reduce material waste and enhance accuracy compared to nip rollers, which primarily serve to press materials together without controlling tension.

Primary Roles of Nip Rollers

Nip rollers primarily function to grip, guide, and control material tension during manufacturing or printing processes, ensuring consistent feed and alignment. They provide precise pressure to maintain uniform contact between layers or surfaces, preventing slippage or distortion. Unlike tension bars that regulate overall web tension, nip rollers specifically manage material handling by applying localized pressure for smooth and accurate material transport.

Structural Differences: Tension Bar vs. Nip Roller

Tension bars are rigid components designed to apply consistent lateral force, maintaining web alignment and preventing slack in material handling systems. Nip rollers consist of paired rotating cylinders that grip and drive the material, offering controlled tension through friction and adjustable pressure. Understanding these structural differences helps you select the appropriate device for efficient web transport and tension control in industrial applications.

Applications in Industrial Processes

Tension bars are primarily used in industrial processes requiring precise control of web tension during material handling, such as in printing, laminating, and coating applications. Nip rollers apply uniform pressure to feed or laminate materials, making them essential for processes like paper manufacturing, textile production, and film extrusion. Both components enhance product quality and process efficiency by stabilizing material flow under varying operational conditions.

Advantages of Using Tension Bars

Tension bars provide consistent web tension control, reducing material waste and preventing web breaks during manufacturing processes. Their mechanical simplicity ensures low maintenance and reliable performance across various materials and speeds. Compared to nip rollers, tension bars offer improved tension uniformity and reduced equipment wear, enhancing overall production efficiency.

Benefits of Implementing Nip Rollers

Nip rollers provide consistent tension control and improved material handling by evenly distributing pressure across the substrate, reducing web breaks and minimizing defects. Their precise grip enhances processing speed and accuracy in applications like printing and laminating, leading to higher product quality and operational efficiency. Implementing nip rollers supports your production line by ensuring smoother web feed, lowering maintenance costs, and increasing overall equipment lifespan.

Performance Comparison: Tension Bar vs. Nip Roller

Tension bars provide consistent web tension control by applying uniform force across the material width, reducing tracking issues and minimizing web breaks in high-speed operations. Nip rollers offer more precise gripping and localized pressure adjustment, enhancing print registration accuracy and enabling smoother substrate feeding through complex machinery. While tension bars excel in maintaining stable tension over long spans, nip rollers are preferred for applications requiring fine control over material positioning and alignment.

Choosing the Right Solution for Your Needs

Selecting between a tension bar and a nip roller depends on your material handling requirements and production speed. Tension bars excel in maintaining consistent web tension for delicate or thin substrates, ensuring precise control without damaging the material. Nip rollers provide stronger grip and are ideal for higher-tension applications, making them suitable for heavier or thicker materials, helping you optimize your process efficiency.

Maintenance and Longevity Considerations

Tension bars require regular inspection for wear and proper tension adjustment to prevent material slippage and maintain consistent web control, while nip rollers demand frequent cleaning and bearing lubrication to avoid surface damage and ensure smooth operation. Longevity of tension bars depends on the quality of the tensioning mechanism and the material of the bar, whereas nip rollers benefit from durable rubber or polyurethane surfaces that resist abrasion and extend service life. Proper maintenance schedules tailored to each component significantly reduce downtime and enhance overall equipment reliability in web handling systems.

Tension bar vs nip roller Infographic

libmatt.com

libmatt.com