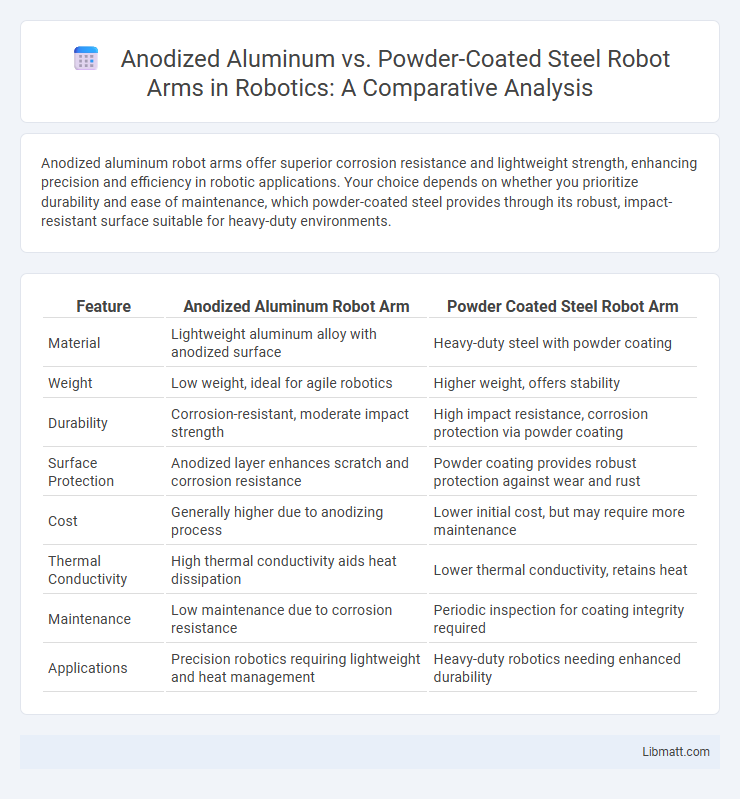

Anodized aluminum robot arms offer superior corrosion resistance and lightweight strength, enhancing precision and efficiency in robotic applications. Your choice depends on whether you prioritize durability and ease of maintenance, which powder-coated steel provides through its robust, impact-resistant surface suitable for heavy-duty environments.

Table of Comparison

| Feature | Anodized Aluminum Robot Arm | Powder Coated Steel Robot Arm |

|---|---|---|

| Material | Lightweight aluminum alloy with anodized surface | Heavy-duty steel with powder coating |

| Weight | Low weight, ideal for agile robotics | Higher weight, offers stability |

| Durability | Corrosion-resistant, moderate impact strength | High impact resistance, corrosion protection via powder coating |

| Surface Protection | Anodized layer enhances scratch and corrosion resistance | Powder coating provides robust protection against wear and rust |

| Cost | Generally higher due to anodizing process | Lower initial cost, but may require more maintenance |

| Thermal Conductivity | High thermal conductivity aids heat dissipation | Lower thermal conductivity, retains heat |

| Maintenance | Low maintenance due to corrosion resistance | Periodic inspection for coating integrity required |

| Applications | Precision robotics requiring lightweight and heat management | Heavy-duty robotics needing enhanced durability |

Introduction: Comparing Robot Arm Materials

Anodized aluminum robot arms offer lightweight strength and enhanced corrosion resistance through an electrochemical process that thickens the natural oxide layer. Powder coated steel robot arms provide superior durability and impact resistance, with a robust protective finish that shields against rust and scratches. Choosing between these materials depends on application requirements for weight, environmental exposure, and mechanical stress tolerance.

Material Properties: Anodized Aluminum Overview

Anodized aluminum offers superior corrosion resistance and enhanced surface hardness due to its oxide layer, making it ideal for robot arms operating in harsh environments. This lightweight material ensures increased maneuverability and efficiency, while maintaining durability against wear and impact. Your choice of anodized aluminum provides a balance of strength and weight reduction compared to powder-coated steel options.

Material Properties: Powder Coated Steel Overview

Powder coated steel offers exceptional durability and corrosion resistance due to its protective polymer layer, making it ideal for heavy-duty robot arms exposed to harsh environments. The coating enhances impact resistance and prevents rust, extending the lifespan of robotic components used in industrial applications. Understanding these material properties ensures your robot arm maintains structural integrity and performance under demanding conditions.

Durability and Corrosion Resistance

Anodized aluminum robot arms exhibit excellent corrosion resistance due to the thick oxide layer formed during the anodizing process, which protects against moisture and chemicals. Powder coated steel arms offer high durability with a robust, impact-resistant finish, yet they may be prone to rust if the coating is chipped or damaged. For long-term outdoor or harsh environment applications, anodized aluminum provides superior corrosion protection, while powder coated steel ensures strength and wear resistance under mechanical stress.

Weight and Structural Strength

Anodized aluminum robot arms offer a significant advantage in weight reduction, making them ideal for applications requiring high maneuverability and lower inertia. Powder coated steel robot arms provide superior structural strength and durability, suitable for heavy-duty tasks demanding high load capacity and impact resistance. Choosing between these materials depends on the balance between lightweight design and maximum strength requirements in robotic applications.

Surface Finish and Aesthetics

Anodized aluminum robot arms offer a sleek, smooth surface finish with enhanced corrosion resistance and a metallic sheen that maintains its appearance over time. Powder coated steel provides a durable, textured finish available in a wide range of colors, protecting against chips and scratches while offering vibrant, customizable aesthetics. Your choice depends on whether you prioritize the modern metallic look and lightweight properties of anodized aluminum or the robust, colorful finish and toughness of powder coated steel.

Maintenance and Longevity

Anodized aluminum robot arms offer superior corrosion resistance and require minimal maintenance due to the durable oxide layer that protects the surface from wear and environmental damage. Powder coated steel arms provide excellent impact resistance and a customizable finish but may need regular inspection and touch-ups to prevent chipping and rust over time. For long-term durability, anodized aluminum excels in harsh or corrosive environments, while powder coated steel delivers robust protection in applications with less exposure to abrasives or moisture.

Cost Efficiency and Manufacturing Considerations

Anodized aluminum robot arms offer superior cost efficiency due to lightweight properties that reduce material usage and lower transportation expenses, while also providing excellent corrosion resistance without additional coatings. Powder coated steel arms require more intensive manufacturing steps including surface preparation and curing, leading to higher production costs but offer enhanced durability and impact resistance. Manufacturers must balance the lower initial cost and easier machining of anodized aluminum against the robustness and maintenance advantages of powder coated steel in industrial robotic applications.

Application Suitability: Industrial and Collaborative Robots

Anodized aluminum robot arms are ideal for collaborative robots due to their lightweight, corrosion resistance, and excellent thermal conductivity, enhancing precision and safety in human-robot interaction environments. Powder coated steel arms offer superior durability and impact resistance, making them well-suited for heavy-duty industrial robots operating in harsh environments or handling high payloads. The choice between anodized aluminum and powder coated steel depends largely on operational demands, weight constraints, and exposure to environmental factors in industrial versus collaborative applications.

Conclusion: Choosing the Right Material for Robotic Arms

Anodized aluminum offers lightweight durability and excellent corrosion resistance, making it ideal for precision robotic arms requiring high strength-to-weight ratios. Powder coated steel provides superior rigidity and impact resistance, well-suited for heavy-duty applications where structural integrity under stress is critical. Selecting the right material depends on balancing factors like weight constraints, environmental exposure, and mechanical demands specific to the robot arm's operational context.

Anodized Aluminum vs Powder Coated Steel Robot Arm Infographic

libmatt.com

libmatt.com