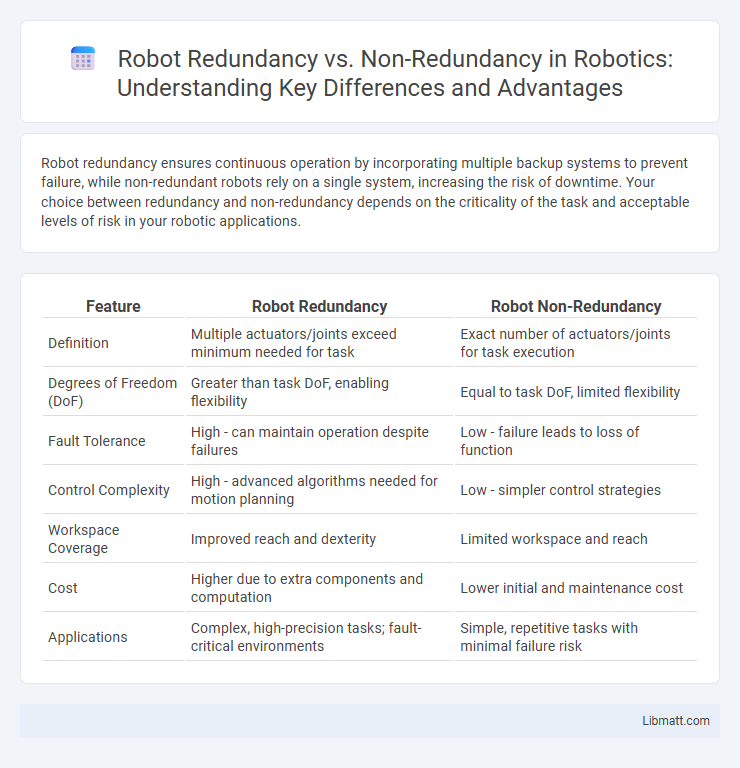

Robot redundancy ensures continuous operation by incorporating multiple backup systems to prevent failure, while non-redundant robots rely on a single system, increasing the risk of downtime. Your choice between redundancy and non-redundancy depends on the criticality of the task and acceptable levels of risk in your robotic applications.

Table of Comparison

| Feature | Robot Redundancy | Robot Non-Redundancy |

|---|---|---|

| Definition | Multiple actuators/joints exceed minimum needed for task | Exact number of actuators/joints for task execution |

| Degrees of Freedom (DoF) | Greater than task DoF, enabling flexibility | Equal to task DoF, limited flexibility |

| Fault Tolerance | High - can maintain operation despite failures | Low - failure leads to loss of function |

| Control Complexity | High - advanced algorithms needed for motion planning | Low - simpler control strategies |

| Workspace Coverage | Improved reach and dexterity | Limited workspace and reach |

| Cost | Higher due to extra components and computation | Lower initial and maintenance cost |

| Applications | Complex, high-precision tasks; fault-critical environments | Simple, repetitive tasks with minimal failure risk |

Introduction to Robot Redundancy

Robot redundancy refers to the inclusion of extra degrees of freedom beyond those required for a task, allowing the robot to achieve greater flexibility and adaptability in complex environments. Redundant robots can optimize motion paths, avoid obstacles, and maintain stability, enhancing their effectiveness in dynamic or constrained spaces. Your choice between redundant and non-redundant robots impacts precision, control complexity, and application suitability, with redundancy offering significant advantages for intricate operations.

Defining Non-Redundant Robots

Non-redundant robots possess degrees of freedom that exactly match the task requirement, typically resulting in simpler control algorithms and less computational complexity. These robots operate within a fixed kinematic structure, limiting their ability to avoid obstacles or singularities compared to redundant robots. Non-redundant robotic arms are commonly used in applications requiring precise and repeatable movements, such as pick-and-place operations in manufacturing.

Key Differences: Redundant vs Non-Redundant Robots

Redundant robots possess more degrees of freedom than the minimum required for a task, enabling greater flexibility, improved fault tolerance, and enhanced capability to avoid obstacles. Non-redundant robots have exactly the necessary degrees of freedom, resulting in simpler design, lower cost, and more straightforward control but limited adaptability and reduced ability to handle joint failures. The key difference lies in redundancy enabling multiple joint configurations for the same end-effector position, offering robustness and precision advantages over non-redundant counterparts.

Advantages of Redundant Robots

Redundant robots offer enhanced flexibility and precision by utilizing extra degrees of freedom, allowing them to navigate complex environments and avoid obstacles more effectively than non-redundant robots. These robots improve task adaptability, enabling smoother motion planning and increased resilience to joint failures or mechanical issues. Their ability to distribute loads and optimize trajectories results in greater operational reliability and improved performance in dynamic industrial applications.

Limitations of Non-Redundant Robotics

Non-redundant robotics systems have limited degrees of freedom, which restrict their ability to perform complex and precise tasks in dynamic environments. These systems often face challenges with singularities and reduced dexterity, impacting your robot's flexibility and overall efficiency. Consequently, non-redundant robots are less adaptable to unexpected obstacles or intricate manipulations compared to redundant counterparts.

Applications Benefiting from Robot Redundancy

Robot redundancy enhances operational flexibility and fault tolerance in complex industrial tasks such as aerospace assembly, medical surgery, and automotive manufacturing. Your robotic systems benefit from increased precision and safety by incorporating multiple degrees of freedom, allowing continuous operation despite individual component failures. Industries demanding high reliability and adaptability, like nuclear facility maintenance and advanced research laboratories, gain substantial advantages from redundant robotic configurations.

Kinematics and Control in Redundant Robots

Redundant robots possess more degrees of freedom than necessary for a given task, enabling enhanced kinematic flexibility and adaptability in motion planning. This redundancy allows for multiple inverse kinematic solutions, improving obstacle avoidance, singularity mitigation, and optimizing secondary objectives like energy efficiency or joint limit avoidance. Your control strategies must leverage this redundancy to achieve precise, smooth, and stable robotic movements by intelligently selecting joint configurations from the infinite possible solutions.

Cost and Complexity Considerations

Robot redundancy increases system cost and complexity due to additional hardware components, sensors, and control algorithms required to ensure fault tolerance and reliability. Non-redundant robots offer lower initial investment and simpler maintenance but may face higher risks of downtime and failure in critical applications. Balancing redundancy with budget constraints and operational needs is essential for optimizing robotic system design.

Future Trends in Redundant Robotics

Future trends in redundant robotics focus on enhancing system reliability and flexibility by incorporating multiple degrees of freedom and fail-safe mechanisms, enabling continuous operation despite component failures. Advances in AI-driven control algorithms optimize redundancy management, improving robot adaptability in complex and dynamic environments. Integration of sensor fusion and real-time diagnostics further advances redundancy, promoting safer and more efficient robotic systems in industrial and service applications.

Choosing Between Redundant and Non-Redundant Robots

When choosing between redundant and non-redundant robots, consider the criticality of your application and the required level of fault tolerance. Redundant robots offer enhanced reliability by incorporating multiple sensors or actuators that allow continuous operation despite component failures, making them ideal for safety-critical or high-availability tasks. Non-redundant robots are typically simpler and more cost-effective, suitable for less demanding environments where occasional downtime is acceptable.

Robot Redundancy vs Non-Redundancy Infographic

libmatt.com

libmatt.com