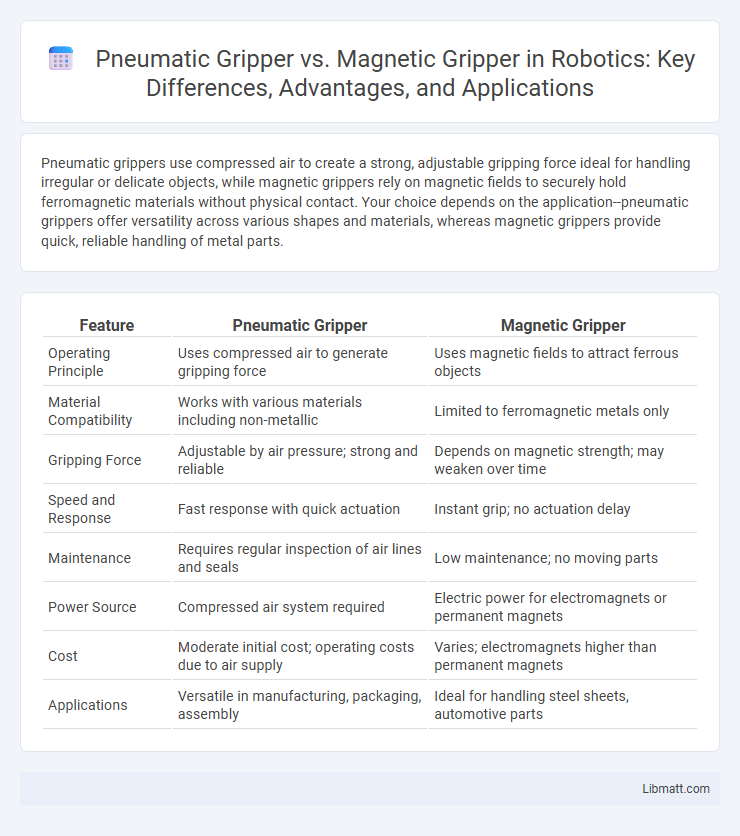

Pneumatic grippers use compressed air to create a strong, adjustable gripping force ideal for handling irregular or delicate objects, while magnetic grippers rely on magnetic fields to securely hold ferromagnetic materials without physical contact. Your choice depends on the application--pneumatic grippers offer versatility across various shapes and materials, whereas magnetic grippers provide quick, reliable handling of metal parts.

Table of Comparison

| Feature | Pneumatic Gripper | Magnetic Gripper |

|---|---|---|

| Operating Principle | Uses compressed air to generate gripping force | Uses magnetic fields to attract ferrous objects |

| Material Compatibility | Works with various materials including non-metallic | Limited to ferromagnetic metals only |

| Gripping Force | Adjustable by air pressure; strong and reliable | Depends on magnetic strength; may weaken over time |

| Speed and Response | Fast response with quick actuation | Instant grip; no actuation delay |

| Maintenance | Requires regular inspection of air lines and seals | Low maintenance; no moving parts |

| Power Source | Compressed air system required | Electric power for electromagnets or permanent magnets |

| Cost | Moderate initial cost; operating costs due to air supply | Varies; electromagnets higher than permanent magnets |

| Applications | Versatile in manufacturing, packaging, assembly | Ideal for handling steel sheets, automotive parts |

Introduction to Pneumatic and Magnetic Grippers

Pneumatic grippers use compressed air to generate a clamping force, making them ideal for handling a wide variety of parts with consistent gripping strength and fast cycle times. Magnetic grippers rely on magnetic fields generated by electromagnets or permanent magnets to securely hold ferrous materials without physical contact, offering clean and non-damaging handling in applications dealing with metal objects. Both types of grippers play a crucial role in automation systems by providing reliable end-of-arm tooling solutions tailored to specific material and process requirements.

How Pneumatic Grippers Work

Pneumatic grippers operate by using compressed air to power a piston within a cylinder, which moves the gripper's jaws to grasp or release objects with precision. The pressure of the air controls the force exerted, making these grippers ideal for handling a variety of parts in automation and robotic applications. Your choice depends on whether the application requires gripping via mechanical force, as with pneumatic grippers, or magnetic attraction, as found in magnetic grippers.

How Magnetic Grippers Work

Magnetic grippers operate by generating a magnetic field using either permanent magnets or electromagnets to securely hold ferromagnetic objects without physical contact. This non-contact gripping method enables precise and gentle handling of materials, reducing wear and minimizing the risk of surface damage. Electromagnetic magnetic grippers allow for easy activation and deactivation through controlled electric current, providing efficient pick-and-place operations in automation systems.

Key Applications of Pneumatic Grippers

Pneumatic grippers excel in high-speed pick-and-place operations, assembly lines, and packaging where precise, repeatable gripping force is essential. They are widely used in automotive manufacturing for handling metal parts, as well as in electronics for delicate component manipulation. Your automated system benefits from pneumatic grippers when strong, reliable grip and fast cycle times are critical to productivity.

Key Applications of Magnetic Grippers

Magnetic grippers excel in handling ferrous materials such as metal sheets, steel parts, and automotive components, making them indispensable in manufacturing and assembly lines. Their ability to securely grip without physical contact helps prevent surface damage, ideal for delicate metal surfaces and thin materials. Common industries leveraging magnetic grippers include automotive, metal fabrication, and electronics, where precision and efficient material handling are critical.

Comparative Strengths: Pneumatic vs. Magnetic Grippers

Pneumatic grippers provide strong gripping force and precise control, making them ideal for handling heavy and irregularly shaped objects in industrial automation. Magnetic grippers excel in non-contact handling of ferromagnetic materials, offering fast attachment and release with minimal wear and maintenance. Your choice depends on the application's material type, gripping force requirements, and operational environment.

Limitations and Challenges of Each Gripper Type

Pneumatic grippers face limitations such as reliance on compressed air, which can cause inconsistent gripping force and higher operational noise, while their mechanical components may wear out under continuous heavy use. Magnetic grippers struggle with handling non-ferrous or partially ferrous materials, creating challenges in versatility and limiting application scope in industries requiring diverse material handling. Both gripper types encounter challenges regarding precision control and adaptability to complex shapes, necessitating careful selection based on specific industrial requirements.

Factors Affecting Gripper Selection

Factors affecting gripper selection include load type, surface material, and operational environment. Pneumatic grippers excel with irregular or heavy objects requiring firm mechanical grip, while magnetic grippers are ideal for ferromagnetic materials, providing non-contact handling. Your choice depends on payload weight, object geometry, and safety requirements to optimize performance and reliability.

Cost and Maintenance Considerations

Pneumatic grippers generally incur higher maintenance costs due to their complex air supply systems and frequent need for seal replacements, while magnetic grippers have lower maintenance expenses with fewer moving parts and no requirement for compressed air. Initial investment in pneumatic grippers is often higher because of the need for compressors and extensive pneumatic components, whereas magnetic grippers tend to be more cost-effective upfront. Over time, the total cost of ownership favors magnetic grippers in applications where longevity and minimal servicing are critical.

Which Gripper is Best for Your Application?

Pneumatic grippers excel in applications requiring strong gripping force and precise handling of diverse shapes due to their adjustable finger configurations and consistent power delivery. Magnetic grippers are ideal for handling ferrous metal objects quickly and cleanly without mechanical contact, offering maintenance-free operation and reduced wear. Your choice depends on the material type, object geometry, and required grip reliability, with pneumatic grippers suited for versatility and magnetic grippers best for metal-specific tasks.

Pneumatic gripper vs Magnetic gripper Infographic

libmatt.com

libmatt.com