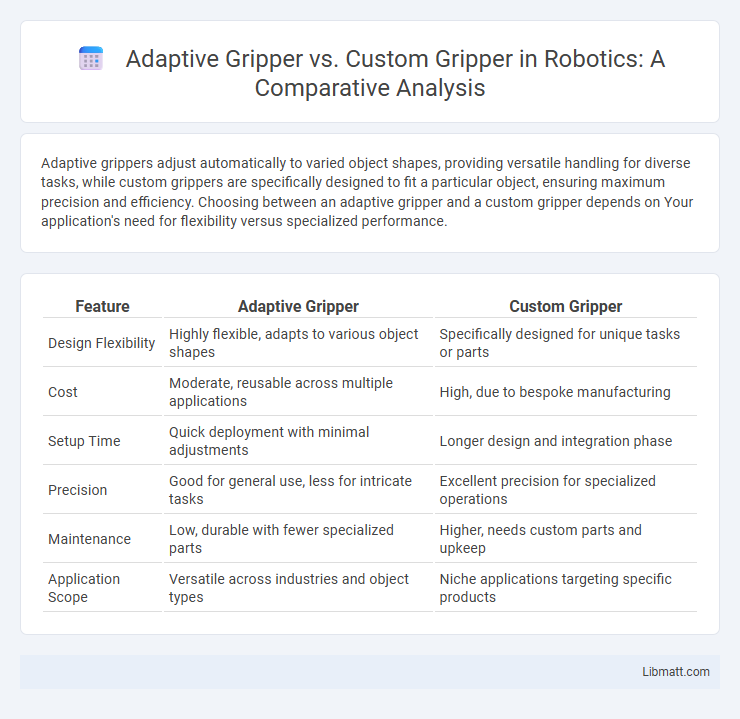

Adaptive grippers adjust automatically to varied object shapes, providing versatile handling for diverse tasks, while custom grippers are specifically designed to fit a particular object, ensuring maximum precision and efficiency. Choosing between an adaptive gripper and a custom gripper depends on Your application's need for flexibility versus specialized performance.

Table of Comparison

| Feature | Adaptive Gripper | Custom Gripper |

|---|---|---|

| Design Flexibility | Highly flexible, adapts to various object shapes | Specifically designed for unique tasks or parts |

| Cost | Moderate, reusable across multiple applications | High, due to bespoke manufacturing |

| Setup Time | Quick deployment with minimal adjustments | Longer design and integration phase |

| Precision | Good for general use, less for intricate tasks | Excellent precision for specialized operations |

| Maintenance | Low, durable with fewer specialized parts | Higher, needs custom parts and upkeep |

| Application Scope | Versatile across industries and object types | Niche applications targeting specific products |

Introduction to Adaptive and Custom Grippers

Adaptive grippers use flexible materials and mechanisms to conform to various object shapes, enabling versatile handling in automation processes. Custom grippers are designed specifically for a unique application or part, offering precision and optimized performance for specialized tasks. Comparing these technologies highlights trade-offs between flexibility and task-specific efficiency in robotic manipulation.

Key Functional Differences

Adaptive grippers use flexible materials and mechanisms to conform to a variety of object shapes, enabling versatile handling without the need for customized tooling. Custom grippers, in contrast, are designed and manufactured specifically for a particular object's geometry, providing high precision and secure grasping for repetitive tasks. The key functional difference lies in the adaptive gripper's ability to handle diverse parts with one design versus the custom gripper's optimized performance for fixed, uniform workpieces.

Design and Engineering Considerations

Adaptive grippers offer flexibility with pre-engineered components that accommodate varied object shapes and sizes, reducing the need for extensive redesign. Custom grippers require detailed engineering to tailor the gripping mechanism precisely to specific applications, ensuring optimal force distribution and durability. Understanding your operational requirements will guide the choice between rapid adaptability and specialized performance in gripper design.

Flexibility and Versatility Comparison

Adaptive grippers offer enhanced flexibility and versatility by automatically adjusting to different object shapes and sizes, making them ideal for varied production lines. Custom grippers, while highly precise for specific tasks, lack the adaptability to handle diverse items without redesign or modification. Choosing an adaptive gripper can optimize your operations by reducing changeover time and increasing the range of objects your robotic system can efficiently manipulate.

Performance in Diverse Applications

Adaptive grippers offer superior performance in diverse applications due to their ability to conform to various shapes and sizes, enabling efficient handling of irregular or fragile objects. Custom grippers excel in repetitive tasks requiring high precision and strength, tailored specifically to a particular part or process. The choice between adaptive and custom grippers depends on the application's complexity, part variability, and required flexibility.

Cost Analysis: Initial Investment and Maintenance

Adaptive grippers typically require a lower initial investment due to their standardized design and compatibility with various tasks, reducing the need for extensive customization. Custom grippers involve higher upfront costs, driven by tailored engineering and materials to meet specific application requirements. Maintenance expenses for adaptive grippers tend to be lower, as their modular components are easier to replace and service, whereas custom grippers may incur higher costs due to specialized parts and limited vendor support.

Integration with Robotic Systems

Adaptive grippers offer seamless integration with a wide range of robotic systems due to their versatile design and standardized interfaces, enabling rapid deployment and reduced programming complexity. Custom grippers require tailored integration efforts to match specific robotic architectures, often involving extensive software customization and hardware modifications. The choice between adaptive and custom grippers significantly impacts system compatibility, control precision, and overall automation efficiency in robotic applications.

Customization Capabilities and Limitations

Custom grippers offer extensive customization capabilities tailored to specific tasks, allowing precise control over shape, material, and functionality to handle unique workpieces effectively. Adaptive grippers provide flexibility by conforming to various object shapes without requiring detailed design adjustments but have limitations in handling highly specialized or delicate items. When your application demands precise handling of unique components, custom grippers deliver superior performance, while adaptive grippers excel in versatility across diverse objects.

Industry Use Cases and Success Stories

Adaptive grippers excel in industries requiring versatile handling of diverse products, such as e-commerce fulfillment centers and food packaging, where their flexibility reduces changeover times and enhances productivity. Custom grippers find strong applications in automotive manufacturing and aerospace assembly, delivering precise, repeatable grasps tailored to specific parts and processes, thereby improving quality and reducing defects. Success stories highlight adaptive grippers enabling fast SKU switches in electronics logistics, while custom grippers contributed to significant cycle-time reductions in high-volume automotive production lines.

Choosing the Right Gripper for Your Needs

Adaptive grippers offer versatile gripping solutions with built-in compliance, making them ideal for handling varied part geometries and fragile items without requiring extensive customization. Custom grippers are engineered specifically for unique applications, providing precise gripping force and shape conformity tailored to your production demands. Assess your application's complexity, part variability, and budget to determine whether the flexibility of adaptive grippers or the specificity of custom grippers best suits your operational requirements.

Adaptive Gripper vs Custom Gripper Infographic

libmatt.com

libmatt.com