Gravity compensation technology reduces the effort needed to lift heavy objects by counteracting their weight, enhancing precision and reducing operator fatigue in robotic arms and exoskeletons. Zero-gravity grippers simulate a weightless environment, allowing your robotic systems to handle delicate or cumbersome items smoothly without the influence of gravity, improving control and minimizing potential damage.

Table of Comparison

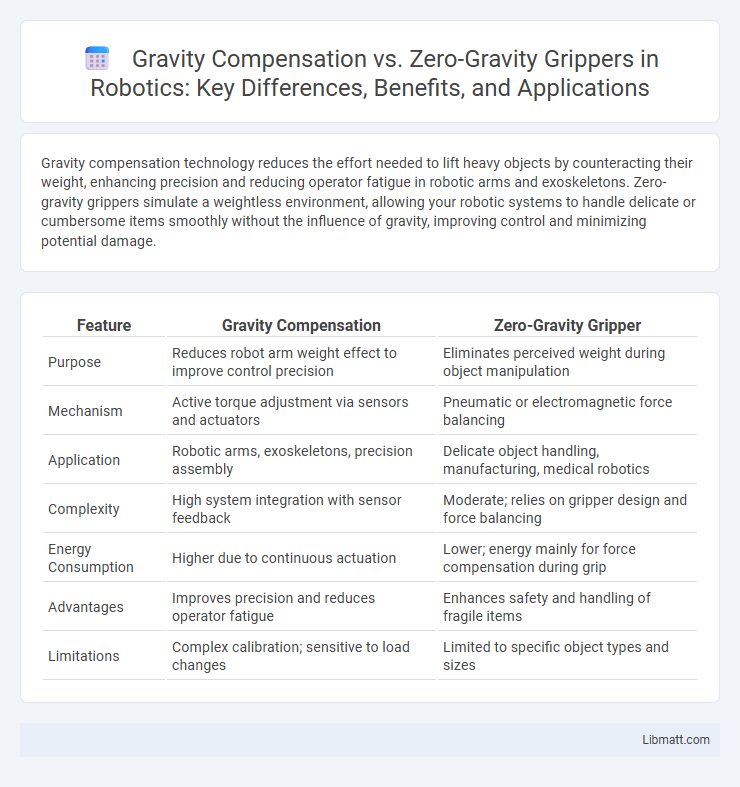

| Feature | Gravity Compensation | Zero-Gravity Gripper |

|---|---|---|

| Purpose | Reduces robot arm weight effect to improve control precision | Eliminates perceived weight during object manipulation |

| Mechanism | Active torque adjustment via sensors and actuators | Pneumatic or electromagnetic force balancing |

| Application | Robotic arms, exoskeletons, precision assembly | Delicate object handling, manufacturing, medical robotics |

| Complexity | High system integration with sensor feedback | Moderate; relies on gripper design and force balancing |

| Energy Consumption | Higher due to continuous actuation | Lower; energy mainly for force compensation during grip |

| Advantages | Improves precision and reduces operator fatigue | Enhances safety and handling of fragile items |

| Limitations | Complex calibration; sensitive to load changes | Limited to specific object types and sizes |

Introduction to Gripper Technologies

Gravity compensation grippers use counterbalancing mechanisms to neutralize the weight of objects, enabling precise manipulation with reduced operator effort. Zero-gravity grippers simulate weightlessness by actively counteracting gravitational forces through advanced sensors and actuators, improving handling of delicate or heavy items in industrial automation. Both technologies enhance robotic gripper performance by addressing the challenges posed by object weight during picking and placing tasks.

Understanding Gravity Compensation Principles

Gravity compensation principles involve counteracting the force of gravity to reduce the effective weight of an object, thereby easing manipulation and improving precision in robotic systems. Unlike zero-gravity grippers, which create a quasi-weightless environment through mechanical design or active control, gravity compensation dynamically adjusts for varying loads and positions to maintain stability. Understanding these principles enables you to optimize robotic performance and reduce operator fatigue during handling tasks.

What is a Zero-Gravity Gripper?

A Zero-Gravity Gripper is a robotic end-effector designed to handle objects with a sensation of weightlessness by counterbalancing gravitational forces, enabling precise and effortless manipulation. Unlike traditional gravity compensation systems that rely on mechanical springs or counterweights to offset an object's weight, zero-gravity grippers use advanced sensors and actuators to maintain stability during movement. Your operations benefit from enhanced control and reduced operator fatigue when deploying zero-gravity grippers in automated assembly or material handling tasks.

Key Differences Between Gravity Compensation and Zero-Gravity Grippers

Gravity compensation systems stabilize robotic arms by counteracting gravitational forces to maintain precise positioning, whereas zero-gravity grippers create a near weightless environment for objects, enabling delicate handling without exerting pressure. Gravity compensation enhances control and reduces operator fatigue in robotics, while zero-gravity grippers prioritize gentle manipulation of fragile items in aerospace or medical applications. Understanding these key differences helps you select the right technology for tasks requiring either stability or ultra-sensitive object handling.

Applications of Gravity Compensation in Automation

Gravity compensation is extensively applied in automation to enhance robotic arm precision and reduce operator fatigue by counteracting the weight of tools or payloads. Industrial robots in assembly lines utilize gravity compensation to maintain stability and smooth motion during complex tasks such as welding, painting, and material handling. Collaborative robots (cobots) leverage gravity compensation to achieve safer human-robot interaction by offering lightweight, intuitive control without sacrificing payload capacity.

Industrial Uses of Zero-Gravity Grippers

Zero-gravity grippers enable precise handling of heavy or delicate objects by creating a weightless effect, reducing strain in automated manufacturing environments. These grippers are essential in industries such as aerospace for assembling large components, electronics for manipulating sensitive parts, and logistics for efficient material handling. Their ability to compensate for gravitational forces enhances productivity and safety in industrial automation processes.

Benefits of Gravity Compensation Grippers

Gravity compensation grippers provide precise load control by counteracting the weight of objects, reducing operator fatigue and increasing handling accuracy. These grippers enable smoother, more stable manipulation in robotic and automated systems, improving safety during material handling processes. Enhanced energy efficiency and extended equipment lifespan result from minimized strain on robotic arms through effective gravity balancing.

Advantages of Zero-Gravity Grippers

Zero-gravity grippers offer enhanced precision and energy efficiency by actively neutralizing the effect of weight during handling, reducing operator fatigue and minimizing damage to delicate objects. Unlike traditional gravity compensation systems that rely on mechanical counterbalances, zero-gravity grippers use advanced sensors and control systems to dynamically adapt to varying load conditions. Your operations benefit from increased safety, smoother motion control, and improved productivity with zero-gravity grippers.

Challenges and Limitations of Each Gripper Type

Gravity compensation grippers face challenges in accurately counterbalancing varying payload weights, leading to limited adaptability in dynamic environments. Zero-gravity grippers often struggle with maintaining a secure hold on irregular or delicate objects due to reliance on suction or magnetic forces, which restricts their use to specific materials and shapes. Your choice between these gripper types should consider the trade-offs between payload versatility and object compatibility to optimize performance in your application.

Choosing the Right Gripper for Your Application

Selecting the right gripper depends on your application's load sensitivity and precision requirements. Gravity compensation grippers excel in handling heavy or bulky objects by counteracting gravitational forces, reducing operator fatigue and improving accuracy. Zero-gravity grippers offer enhanced maneuverability and stability for delicate or highly precise tasks by minimizing the effective weight of the payload, making them ideal for electronics assembly or medical device manipulation.

Gravity Compensation vs Zero-Gravity Gripper Infographic

libmatt.com

libmatt.com