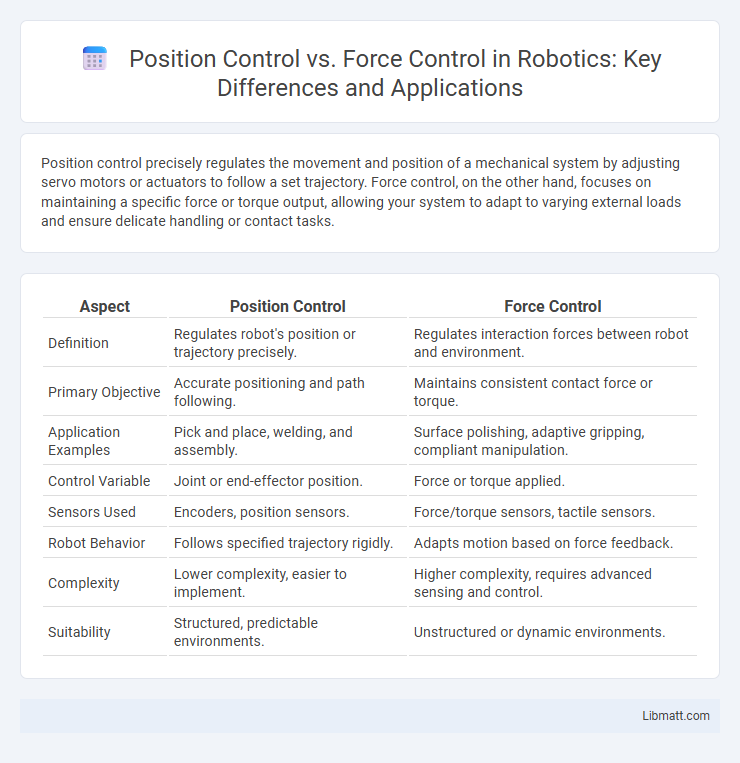

Position control precisely regulates the movement and position of a mechanical system by adjusting servo motors or actuators to follow a set trajectory. Force control, on the other hand, focuses on maintaining a specific force or torque output, allowing your system to adapt to varying external loads and ensure delicate handling or contact tasks.

Table of Comparison

| Aspect | Position Control | Force Control |

|---|---|---|

| Definition | Regulates robot's position or trajectory precisely. | Regulates interaction forces between robot and environment. |

| Primary Objective | Accurate positioning and path following. | Maintains consistent contact force or torque. |

| Application Examples | Pick and place, welding, and assembly. | Surface polishing, adaptive gripping, compliant manipulation. |

| Control Variable | Joint or end-effector position. | Force or torque applied. |

| Sensors Used | Encoders, position sensors. | Force/torque sensors, tactile sensors. |

| Robot Behavior | Follows specified trajectory rigidly. | Adapts motion based on force feedback. |

| Complexity | Lower complexity, easier to implement. | Higher complexity, requires advanced sensing and control. |

| Suitability | Structured, predictable environments. | Unstructured or dynamic environments. |

Understanding Position Control: Fundamentals and Applications

Position control involves regulating the exact location or trajectory of a mechanical system using feedback from sensors such as encoders or potentiometers to achieve precise movement. It is widely applied in robotic arms, CNC machines, and automation systems where accuracy in displacement and path following is critical. The core principles rely on closed-loop control algorithms, typically PID controllers, to minimize position error and ensure stable, repeatable motion performance.

Force Control Explained: Principles and Use Cases

Force control involves regulating the amount of force applied by a robotic system, ensuring precise interaction with objects and environments, which is crucial in tasks like assembly, polishing, and handling delicate materials. It relies on sensors and feedback mechanisms to maintain desired force levels, adapting to varying conditions to prevent damage or ensure quality. Common use cases include robotic surgery, where precise force application is vital, and automated manufacturing processes requiring consistent pressure control.

Key Differences Between Position and Force Control

Position control regulates an actuator's movement to achieve precise placement based on predefined coordinates, while force control adjusts the applied force to maintain desired interaction pressures with the environment. Position control excels in tasks requiring accurate trajectory tracking, such as robotic arm articulation, whereas force control is essential in applications involving variable contact forces, like assembly or surface polishing. Understanding these key differences helps you select the appropriate control strategy for maximizing efficiency and safety in automation systems.

When to Use Position Control in Robotics

Position control in robotics is ideal when precise movement and exact positioning of robotic arms or end-effectors are required, such as in assembly lines, pick-and-place tasks, and CNC machining. It excels in applications where maintaining accurate trajectories and repeatability is critical, especially in structured environments with known constraints. Use position control when the primary objective is to achieve specific coordinates or orientations without the necessity to regulate interaction forces with the environment.

Optimal Scenarios for Force Control Implementation

Force control is optimal in scenarios requiring precise interaction with unknown or dynamic environments, such as robotic assembly, surface finishing, and biomedical applications. It allows your system to adapt to varying contact forces, ensuring safety and accuracy during delicate operations. Position control is less effective in these cases because it lacks the flexibility to respond to external forces in real time.

Advantages and Limitations of Position Control

Position control offers precise regulation of an object's location, making it ideal for applications requiring exact movement such as robotics and CNC machines. Its advantages include high accuracy, repeatability, and ease of implementation with encoders or potentiometers. Limitations arise when interacting with unpredictable environments, as position control lacks the ability to adapt to external force variations, potentially causing damage or reduced performance in tasks involving contact or force feedback.

Pros and Cons of Force Control Systems

Force control systems offer precise interaction with environments by regulating the amount of force applied, ideal for delicate tasks like assembly or machining to prevent damage. Their main advantage lies in adaptability to variable conditions and safety in handling fragile objects, but they can be complex and costly to implement due to sensor requirements and control algorithms. You may face challenges in maintaining stability and performance under dynamic or unpredictable loads, requiring sophisticated tuning and robust hardware.

Integration Challenges: Position vs Force Control

Integration challenges in position control primarily involve achieving precise trajectory tracking and managing system stiffness to avoid overshoot or oscillations. Force control integration requires accurate force sensing and impedance tuning to maintain stable interaction with variable environments, which is complicated by sensor noise and dynamic uncertainties. Balancing these control schemes demands sophisticated algorithms that can seamlessly switch or blend position and force objectives for optimal robotic manipulation.

Real-World Examples: Position and Force Control in Action

Position control is crucial in robotic assembly lines where precise movement and placement of components ensure product quality, such as in automotive manufacturing. Force control plays a vital role in delicate tasks like robotic surgery, where maintaining consistent pressure prevents tissue damage. Your choice between these controls depends on whether accurate positioning or sensitive force application is essential for the task.

Choosing Between Position and Force Control: Decision Factors

Choosing between position control and force control depends primarily on the application's precision and interaction requirements. Position control is ideal for tasks demanding accurate placement or trajectory tracking, such as robotic assembly or CNC machining. In contrast, force control is preferred when adapting to varying environmental forces is critical, like robotic gripping or surface finishing, ensuring compliance and preventing damage.

Position control vs Force control Infographic

libmatt.com

libmatt.com