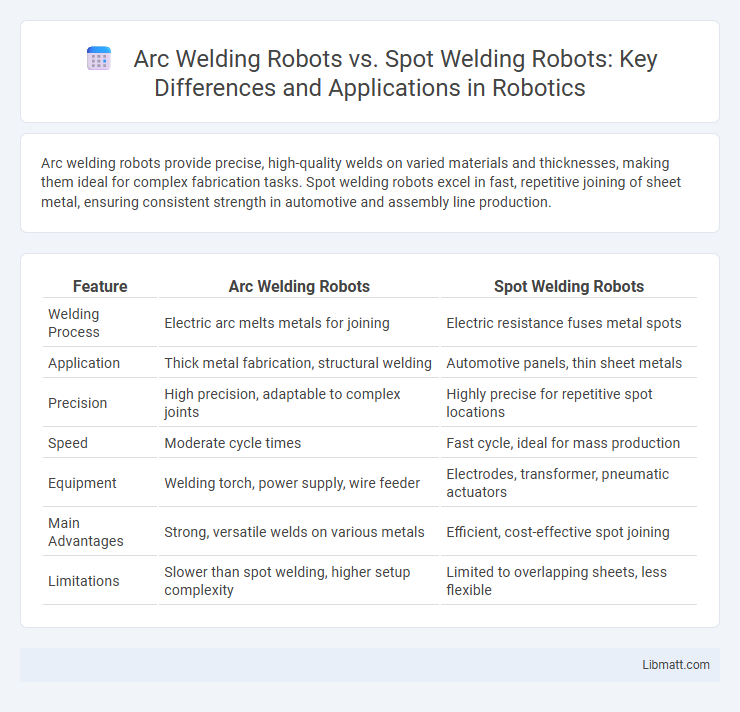

Arc welding robots provide precise, high-quality welds on varied materials and thicknesses, making them ideal for complex fabrication tasks. Spot welding robots excel in fast, repetitive joining of sheet metal, ensuring consistent strength in automotive and assembly line production.

Table of Comparison

| Feature | Arc Welding Robots | Spot Welding Robots |

|---|---|---|

| Welding Process | Electric arc melts metals for joining | Electric resistance fuses metal spots |

| Application | Thick metal fabrication, structural welding | Automotive panels, thin sheet metals |

| Precision | High precision, adaptable to complex joints | Highly precise for repetitive spot locations |

| Speed | Moderate cycle times | Fast cycle, ideal for mass production |

| Equipment | Welding torch, power supply, wire feeder | Electrodes, transformer, pneumatic actuators |

| Main Advantages | Strong, versatile welds on various metals | Efficient, cost-effective spot joining |

| Limitations | Slower than spot welding, higher setup complexity | Limited to overlapping sheets, less flexible |

Introduction to Robotic Welding

Robotic welding integrates automation technology to enhance precision and efficiency in manufacturing processes. Arc welding robots utilize a continuous electrical arc to join metals, ideal for long seams and heavy-duty structures. Spot welding robots apply localized pressure and heat to fasten overlapping metal sheets, commonly used in automotive assembly for high-speed and consistent welds.

Overview of Arc Welding Robots

Arc welding robots utilize automated systems to perform welding by generating an electric arc between an electrode and the workpiece, producing high-quality, consistent welds with precision. These robots excel in applications requiring deep penetration welds on thick materials, commonly used in automotive manufacturing and heavy industries for structural assembly. Your production efficiency can significantly increase due to their ability to operate continuously under harsh conditions while maintaining optimal weld integrity.

Overview of Spot Welding Robots

Spot welding robots are specialized automation systems designed to perform resistance spot welding with high precision and speed, primarily used in automotive and metal fabrication industries. These robots deliver consistent weld quality by accurately controlling electrode force, current, and timing, enhancing productivity and reducing labor costs. Integration with advanced sensors and programming allows spot welding robots to handle complex assemblies while minimizing defects and rework.

Key Differences Between Arc and Spot Welding Robots

Arc welding robots use an electric arc to melt and join metals, producing deep, precise welds suitable for thick materials, while spot welding robots employ resistance heat generated at the interface of two metal surfaces to create welds primarily in sheet metal applications. The key differences lie in their welding techniques: arc welding offers versatility with various welding processes like MIG or TIG, whereas spot welding is faster and ideal for high-speed, repetitive tasks in automotive assembly. Your choice between these robots depends on material thickness, production speed, and weld type requirements.

Applications in Various Industries

Arc welding robots are extensively used in heavy industries such as automotive manufacturing, shipbuilding, and construction for joining thick metal components with precision and strength. Spot welding robots dominate the electronics and automotive sectors for assembling sheet metal parts and producing lightweight, high-volume products efficiently. Both technologies enhance productivity and consistency in metal fabrication but cater to different material thicknesses and joint types.

Precision and Quality Comparison

Arc welding robots deliver high precision with consistent weld quality, making them ideal for complex and large-scale metal fabrication requiring deep penetration and strong joints. Spot welding robots excel in producing precise, repetitive welds on sheet metal, ensuring uniformity and strength in automotive and manufacturing assembly lines. Your choice depends on whether you need intricate, high-quality welds from arc welding or the fast, reliable spot welds ideal for high-volume production.

Speed and Efficiency Considerations

Arc welding robots offer high-speed welding suitable for continuous seams and thick materials, delivering consistent weld quality with precise control over heat input. Spot welding robots excel in rapid, repetitive tasks, particularly in automotive assembly lines, where speed and cycle time are critical for joining sheet metals efficiently. Efficiency in spot welding robots is enhanced by their ability to perform multiple welds simultaneously, while arc welding robots optimize throughput through adaptive programming for varied welding patterns.

Cost Implications and ROI

Arc welding robots typically require higher initial investment due to their complex machinery and versatility, but provide greater returns over time through increased precision and adaptability across various materials. Spot welding robots, with lower upfront costs and faster cycle times, offer quicker ROI in high-volume production environments such as automotive assembly lines. Choosing between these technologies hinges on balancing upfront capital expenditure against long-term efficiency gains and production scale.

Safety and Maintenance Factors

Arc welding robots require robust safety measures due to high voltage and intense UV radiation, including protective barriers and automated shutdown systems to prevent operator exposure. In contrast, spot welding robots feature localized heat generation and lower voltage risks, but demand precise electrode maintenance to avoid weld defects and ensure consistent performance. Regular inspections and preventive maintenance protocols are essential for both types to minimize downtime and extend equipment lifespan.

Choosing the Right Welding Robot for Your Needs

Arc welding robots excel in versatility, handling various metals and thicknesses with precision, ideal for large-scale fabrication and complex seams. Spot welding robots specialize in high-speed, repetitive tasks on sheet metals, making them perfect for automotive and electronics assembly that demands consistent weld quality. Selecting the right welding robot depends on factors like material type, production volume, and joint configuration to optimize efficiency and weld integrity.

Arc Welding vs Spot Welding Robots Infographic

libmatt.com

libmatt.com