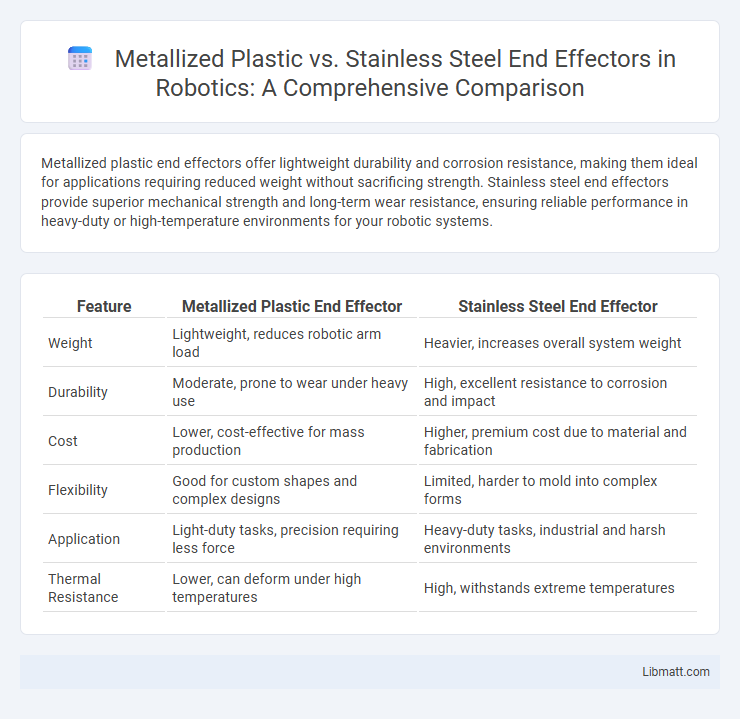

Metallized plastic end effectors offer lightweight durability and corrosion resistance, making them ideal for applications requiring reduced weight without sacrificing strength. Stainless steel end effectors provide superior mechanical strength and long-term wear resistance, ensuring reliable performance in heavy-duty or high-temperature environments for your robotic systems.

Table of Comparison

| Feature | Metallized Plastic End Effector | Stainless Steel End Effector |

|---|---|---|

| Weight | Lightweight, reduces robotic arm load | Heavier, increases overall system weight |

| Durability | Moderate, prone to wear under heavy use | High, excellent resistance to corrosion and impact |

| Cost | Lower, cost-effective for mass production | Higher, premium cost due to material and fabrication |

| Flexibility | Good for custom shapes and complex designs | Limited, harder to mold into complex forms |

| Application | Light-duty tasks, precision requiring less force | Heavy-duty tasks, industrial and harsh environments |

| Thermal Resistance | Lower, can deform under high temperatures | High, withstands extreme temperatures |

Introduction to End Effectors

End effectors serve as the critical interface between robotic arms and objects, enabling precise manipulation in automation tasks. Metallized plastic end effectors combine lightweight properties with enhanced conductivity and wear resistance through metal coating, offering flexibility in handling delicate items. Stainless steel end effectors provide superior strength, corrosion resistance, and durability for heavy-duty applications requiring robust performance in harsh environments.

Overview of Metallized Plastic End Effectors

Metallized plastic end effectors combine lightweight plastic substrates with a thin metallic coating, offering enhanced electrical conductivity, corrosion resistance, and reduced weight compared to traditional metal components. These end effectors are commonly used in applications requiring delicate handling, electrical grounding, or electromagnetic shielding while maintaining flexibility and cost-efficiency. Their durability and adaptability make them ideal for industries such as electronics manufacturing, robotics, and automated assembly lines.

Key Properties of Stainless Steel End Effectors

Stainless steel end effectors are prized for their exceptional corrosion resistance, high strength-to-weight ratio, and superior durability in harsh industrial environments. Their non-reactive surface and ease of sterilization make them ideal for applications in food processing, pharmaceuticals, and cleanroom settings. Precision machining and thermal stability further enhance their performance in automated robotic handling tasks requiring consistent accuracy and reliability.

Weight Comparison: Metallized Plastic vs Stainless Steel

Metallized plastic end effectors offer a significant weight advantage over stainless steel counterparts, often reducing the overall weight by up to 50-70%. This reduction in weight enhances robotic arm agility and decreases energy consumption during operations. Your choice of metallized plastic can improve efficiency without compromising structural integrity in many applications.

Durability and Strength Analysis

Metallized plastic end effectors offer lightweight advantages but generally exhibit lower durability and strength compared to stainless steel counterparts, which provide superior resistance to wear, corrosion, and mechanical stress. Stainless steel end effectors maintain structural integrity under high load conditions and harsh environments, making them ideal for heavy-duty industrial applications. The metallization layer on plastic components may enhance surface properties but does not significantly improve the inherent mechanical strength compared to stainless steel.

Cost Efficiency and Manufacturing Considerations

Metallized plastic end effectors offer cost efficiency through lower material expenses and faster manufacturing cycles compared to stainless steel, making them ideal for high-volume or prototype production. Stainless steel end effectors provide superior durability and resistance to wear, which can reduce long-term maintenance costs despite higher initial investment. Your choice depends on balancing upfront manufacturing costs with the expected lifespan and performance requirements of the application.

Corrosion Resistance and Chemical Compatibility

Metallized plastic end effectors offer excellent chemical compatibility with acidic and alkaline substances, making them ideal for environments where corrosion could degrade stainless steel components. Stainless steel end effectors exhibit superior corrosion resistance in neutral and mildly corrosive environments, maintaining structural integrity under mechanical stress and high temperatures. Your choice should consider the specific chemical exposure and operational conditions to optimize durability and performance.

Customization and Design Flexibility

Metallized plastic end effectors offer greater customization and design flexibility due to their lightweight properties and ease of molding into complex shapes. Stainless steel end effectors provide exceptional durability and precision but have limited design adaptability because of their rigid structure and manufacturing constraints. Choosing between metallized plastic and stainless steel depends on application requirements for intricate designs versus robustness and longevity.

Industry Applications: Choosing the Right Material

Metallized plastic end effectors offer lightweight and corrosion-resistant solutions ideal for electronics assembly and delicate handling in automation industries. Stainless steel end effectors provide superior strength, durability, and resistance to high temperatures, making them suitable for heavy-duty applications in automotive manufacturing and food processing. Your choice should align with the specific environmental conditions and precision requirements of your industrial application.

Conclusion: Selecting the Optimal End Effector Material

Choosing between metallized plastic and stainless steel end effectors depends on factors like durability, weight, and application environment. Stainless steel offers superior strength and corrosion resistance for heavy-duty or high-temperature tasks, while metallized plastic provides a lightweight, cost-effective option suitable for less demanding applications. Your selection should align with performance requirements and operational conditions to ensure optimal functionality and longevity.

Metallized Plastic vs Stainless Steel End Effector Infographic

libmatt.com

libmatt.com