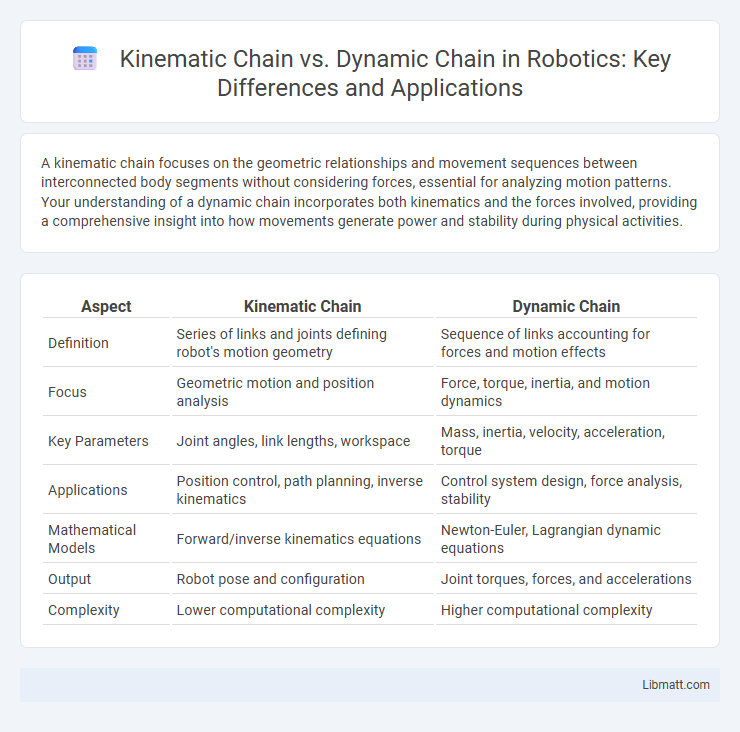

A kinematic chain focuses on the geometric relationships and movement sequences between interconnected body segments without considering forces, essential for analyzing motion patterns. Your understanding of a dynamic chain incorporates both kinematics and the forces involved, providing a comprehensive insight into how movements generate power and stability during physical activities.

Table of Comparison

| Aspect | Kinematic Chain | Dynamic Chain |

|---|---|---|

| Definition | Series of links and joints defining robot's motion geometry | Sequence of links accounting for forces and motion effects |

| Focus | Geometric motion and position analysis | Force, torque, inertia, and motion dynamics |

| Key Parameters | Joint angles, link lengths, workspace | Mass, inertia, velocity, acceleration, torque |

| Applications | Position control, path planning, inverse kinematics | Control system design, force analysis, stability |

| Mathematical Models | Forward/inverse kinematics equations | Newton-Euler, Lagrangian dynamic equations |

| Output | Robot pose and configuration | Joint torques, forces, and accelerations |

| Complexity | Lower computational complexity | Higher computational complexity |

Introduction to Kinematic and Dynamic Chains

Kinematic chains describe interconnected rigid bodies linked by joints to analyze movement patterns without considering forces, forming the basis for understanding mechanical motion. Dynamic chains extend this concept by incorporating the effects of forces and torques, crucial for studying the real-time behavior of mechanical systems under load. Your grasp of kinematic and dynamic chains enables precise modeling of robotic arms, biomechanics, and machinery performance.

Defining Kinematic Chain

A kinematic chain refers to a series of connected rigid bodies or links joined by joints that constrain their relative motion, forming the foundation for analyzing mechanical systems and human movement. Each joint in a kinematic chain allows specific degrees of freedom, enabling precise control over position and orientation without considering forces or torques. Understanding your body's kinematic chain is essential for optimizing movement efficiency and preventing injury during physical activities.

Understanding Dynamic Chain

Dynamic chain refers to the interconnected segments of the body or mechanical system that move and interact through forces, momentum, and muscular activity, enabling coordinated motion and power transfer. It emphasizes the role of active muscle contractions and external forces rather than just the rigid linkages found in a kinematic chain. Understanding dynamic chains is crucial for optimizing movement efficiency in sports science, rehabilitation, and robotics by analyzing how force generation and transfer influence overall performance and stability.

Key Differences Between Kinematic and Dynamic Chains

Kinematic chains primarily describe the geometric and motion relationships between links and joints, focusing on velocity, acceleration, and displacement without considering forces. Dynamic chains extend this by incorporating forces and torques, analyzing how these affect motion and system behavior through Newtonian mechanics. Your understanding of mechanical systems improves significantly by distinguishing kinematic constraints from dynamic forces, crucial for accurate modeling and control.

Types of Kinematic Chains

Kinematic chains are classified into open and closed types, where open chains have a free end allowing for unlimited movement, while closed chains form loops providing greater stability and force transmission. In contrast, dynamic chains focus on the forces and motion within these linkages during movement, emphasizing the interaction of masses, inertia, and external loads. Understanding the types of kinematic chains can enhance your ability to analyze mechanical systems and optimize performance in robotics, biomechanics, and machinery design.

Types of Dynamic Chains

Dynamic chains include open dynamic chains, where segments move independently without fixed base constraints, and closed dynamic chains, characterized by interconnected segments forming loops that restrict motion paths. Parallel dynamic chains involve multiple branches operating simultaneously under coordinated control, enhancing system stability and load distribution. Hybrid dynamic chains combine serial and parallel elements to optimize flexibility and strength in complex mechanical systems.

Applications in Mechanical Systems

Kinematic chains are widely used in robotic arms and mechanical linkages where precise motion control and position analysis are critical, enabling tasks like assembly automation and machine tool operation. Dynamic chains extend kinematic principles by incorporating forces, torques, and mass to analyze system behavior under load, essential for vehicle suspension design and biomechanics simulations. Understanding both chains enhances your ability to optimize mechanical systems for stability, efficiency, and performance in dynamic environments.

Importance in Robotics and Biomechanics

Kinematic chains define the interconnected rigid bodies and joints crucial for analyzing robotic arm movement and human limb mechanics, ensuring precise control and motion prediction. Dynamic chains incorporate forces and torques acting on each segment, enabling accurate modeling of real-world interactions in both robot manipulation and biomechanical load assessments. Understanding the interplay between kinematic and dynamic chains enhances the development of efficient robot controllers and aids in injury prevention by simulating human movement under various conditions.

Advantages and Limitations

Kinematic chains offer precise control and stability in mechanical systems by focusing on rigid body motion, making them ideal for predictable movement in robotics and machinery. However, their limitation lies in handling external forces and real-time changes, as they do not account for dynamics such as inertia or acceleration. Dynamic chains incorporate forces and motion laws, providing advantages in simulating realistic behavior and adaptability in complex environments, though they demand higher computational resources and can be more challenging to model accurately.

Conclusion: Choosing the Right Chain for Your System

Selecting the appropriate chain depends on the specific requirements of your mechanical system, where kinematic chains excel in predictable motion and precise positioning, while dynamic chains are better suited for handling forces, energy transfer, and variable loads. Evaluating factors like system complexity, load characteristics, and desired motion control ensures optimal performance and longevity. Proper analysis leads to enhanced efficiency and reduced mechanical wear by matching the chain type to the application's functional demands.

Kinematic Chain vs Dynamic Chain Infographic

libmatt.com

libmatt.com