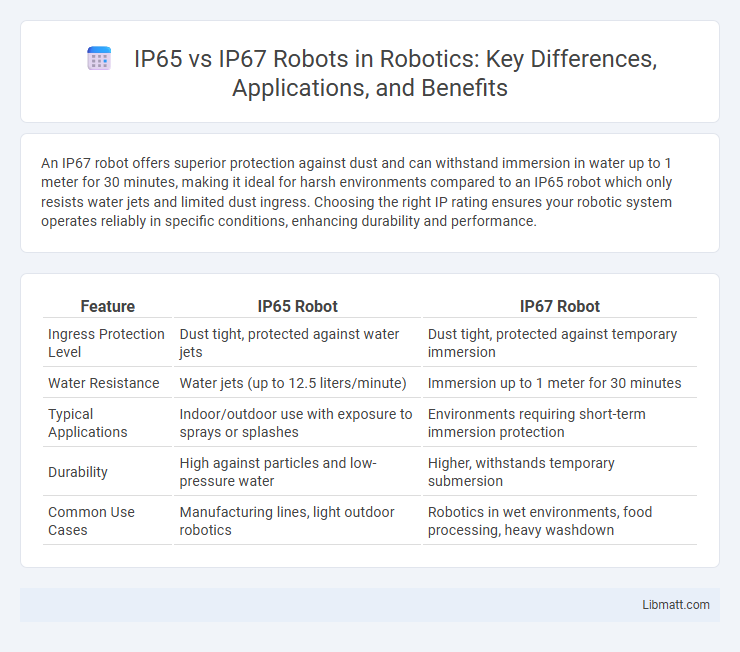

An IP67 robot offers superior protection against dust and can withstand immersion in water up to 1 meter for 30 minutes, making it ideal for harsh environments compared to an IP65 robot which only resists water jets and limited dust ingress. Choosing the right IP rating ensures your robotic system operates reliably in specific conditions, enhancing durability and performance.

Table of Comparison

| Feature | IP65 Robot | IP67 Robot |

|---|---|---|

| Ingress Protection Level | Dust tight, protected against water jets | Dust tight, protected against temporary immersion |

| Water Resistance | Water jets (up to 12.5 liters/minute) | Immersion up to 1 meter for 30 minutes |

| Typical Applications | Indoor/outdoor use with exposure to sprays or splashes | Environments requiring short-term immersion protection |

| Durability | High against particles and low-pressure water | Higher, withstands temporary submersion |

| Common Use Cases | Manufacturing lines, light outdoor robotics | Robotics in wet environments, food processing, heavy washdown |

Understanding IP Ratings: What Do IP65 and IP67 Mean?

IP65 and IP67 are Ingress Protection ratings that define a robot's resistance to dust and water. IP65 ensures complete dust-tight protection and water jets from any direction, making it suitable for general industrial environments. IP67 offers a higher standard by allowing full dust protection plus immersion in water up to 1 meter for 30 minutes, ideal for harsher conditions requiring temporary submersion tolerance.

Key Differences Between IP65 and IP67 Robots

IP65 robots offer protection against dust and low-pressure water jets, making them suitable for general industrial environments where occasional splashes occur. IP67 robots provide a higher level of protection, with full dust-tight sealing and the ability to withstand temporary immersion in water up to 1 meter deep for 30 minutes. Your choice between IP65 and IP67 robots depends on the specific environmental challenges, such as exposure to dust or the risk of submersion, ensuring optimal durability and performance.

Water and Dust Protection: IP65 vs IP67 Comparison

IP65-rated robots offer protection against dust ingress and withstand low-pressure water jets from any direction, ensuring reliable operation in moderately wet environments. In contrast, IP67 robots provide complete dust-tight sealing and can endure temporary immersion in water up to 1 meter depth for 30 minutes, making them ideal for harsher, underwater conditions. Choosing between IP65 and IP67 depends on the robot's exposure to water depth and dust levels in its operating environment.

Environmental Suitability: Where to Use IP65 and IP67 Robots

IP65 robots are best suited for environments with moderate exposure to dust and water, such as indoor manufacturing floors or areas with occasional splashes. IP67 robots are designed for harsher conditions involving temporary immersion in water or heavy dust, making them ideal for outdoor settings, food processing facilities, or washdown zones. Selecting between IP65 and IP67 depends on the specific environmental challenges, ensuring optimal protection and operational reliability.

Performance in Wet Conditions: IP65 Robots vs IP67 Robots

IP65 robots are designed to withstand low-pressure water jets, making them suitable for environments with limited moisture exposure, while IP67 robots offer superior protection by being fully resistant to dust and capable of withstanding immersion in water up to 1 meter for 30 minutes. Your choice between IP65 and IP67 robots should consider the operational environment's water exposure level, with IP67 models preferred for tasks involving frequent or prolonged wet conditions. The enhanced sealing in IP67 robots ensures higher reliability and longer lifespan in wet and dusty industrial settings.

Cost Considerations: Is IP67 Worth the Investment Over IP65?

IP67-rated robots offer superior protection against dust and temporary immersion in water compared to IP65 models, which are resistant only to water jets and dust ingress. The higher cost of IP67 robots reflects enhanced sealing and durability, ideal for harsh industrial environments requiring frequent washdowns or exposure to moisture. Your investment in an IP67 robot can yield long-term savings by reducing downtime and maintenance expenses in conditions where IP65 protection might fall short.

Longevity and Maintenance: Impact of IP65 vs IP67 Ratings

IP67-rated robots offer superior protection against dust and water immersion up to 1 meter for 30 minutes, significantly enhancing longevity in harsh environments compared to IP65-rated robots, which only protect against water jets. This increased ingress protection reduces the frequency of maintenance caused by moisture or particulate damage, minimizing downtime and extending your robot's operational life. Choosing an IP67 robot ensures better durability and lower long-term maintenance costs in demanding industrial settings.

Industry Applications: Choosing the Right IP Rating for Your Robot

IP65-rated robots are ideal for industrial environments where protection against dust and low-pressure water jets is essential, such as automotive assembly lines and food processing plants. IP67-rated robots offer enhanced protection, capable of withstanding temporary immersion in water, making them suitable for heavy washdown areas like pharmaceutical manufacturing or outdoor applications exposed to rain. Selecting the correct IP rating ensures your robot's durability and efficiency in specific industry conditions, optimizing operational reliability and reducing maintenance costs.

Testing Standards: How IP65 and IP67 Robots Are Certified

IP65 and IP67 robots undergo rigorous testing standards based on the IEC 60529 international code for Ingress Protection ratings to ensure their durability against dust and water. IP65 certification requires protection against water jets from any direction and complete dust ingress prevention, while IP67 robots must withstand immersion in water up to 1 meter for 30 minutes along with total dust protection. These tests involve simulated environmental conditions to validate the robot's enclosure integrity, ensuring reliability in industrial applications where exposure to harsh elements is common.

Making the Right Choice: Factors to Consider When Selecting IP65 or IP67 Robots

Selecting between IP65 and IP67 robots depends on the specific environmental conditions and application requirements. IP65 robots are suitable for protection against low-pressure water jets and limited dust exposure, making them ideal for general industrial settings. IP67 robots offer superior protection with complete dust tightness and the ability to withstand temporary immersion in water, essential for more demanding environments where robots may face submersion or heavy contamination.

IP65 vs IP67 Robot Infographic

libmatt.com

libmatt.com